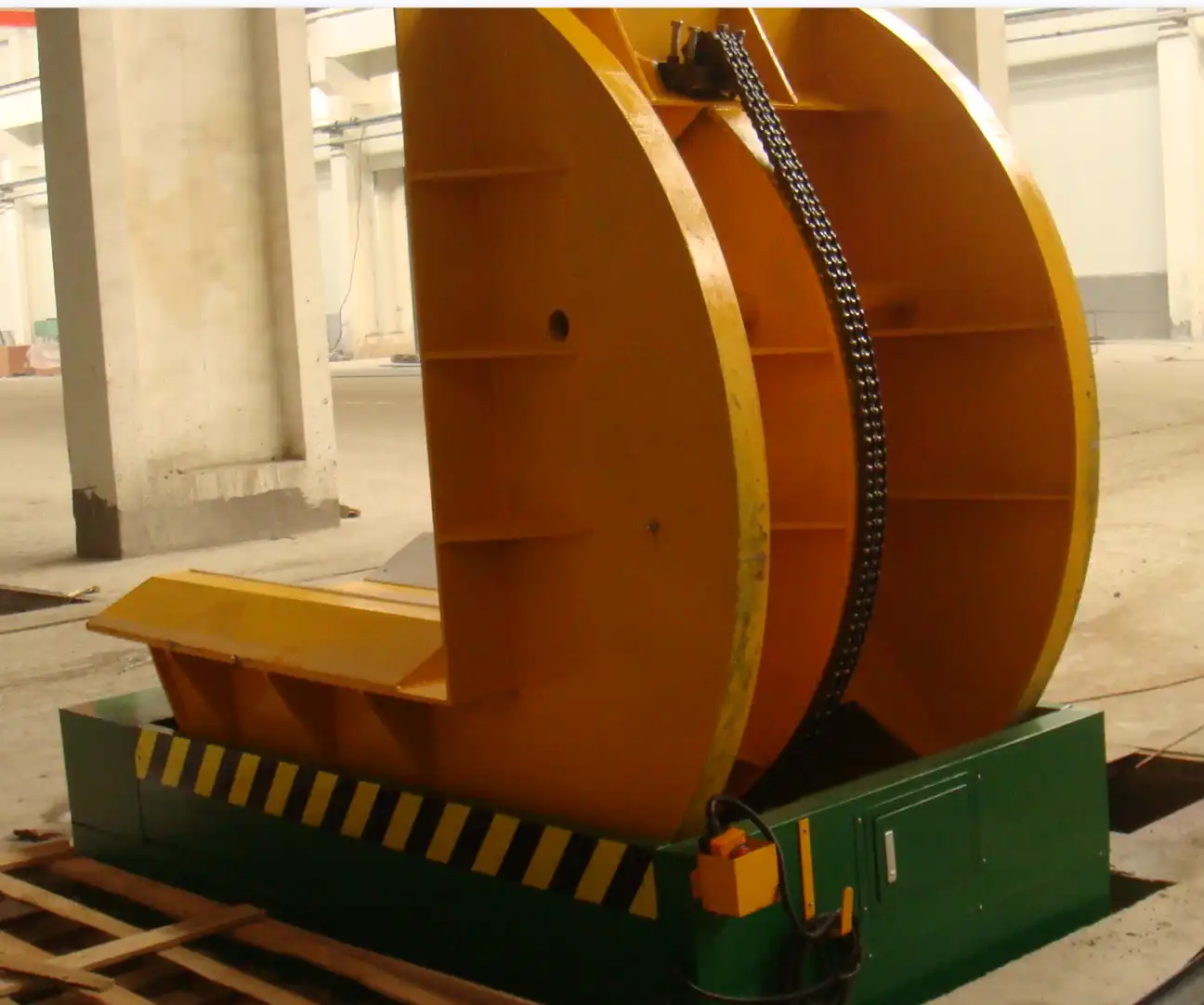

Transform Your Workshop Safety Standards with a Heavy-Duty Coil Upender?

Leading Paragraph:

Are you struggling with workplace injuries and production bottlenecks in your metal processing plant? Every time your workers manually handle heavy steel coils, you're risking serious accidents that can shut down your entire operation. The constant strain of manual coil flipping not only endangers your team but also slows down your packing line, creating costly delays that impact your bottom line. What if you could eliminate these risks while boosting your efficiency?

Snippet Paragraph:

A heavy-duty coil upender transforms workshop safety by automating the most dangerous part of coil handling - the flipping and positioning process. Key benefits include: eliminating manual handling of heavy coils, reducing workplace injury risks by up to 80%, and increasing packing line efficiency by 30-50%. These machines provide controlled, mechanical rotation that keeps operators at a safe distance from moving loads.

Transition Paragraph:

But how exactly does a coil upender achieve these safety improvements, and what should you look for when choosing the right equipment for your Mexican factory? Let me break down the critical factors based on my 20+ years in the coil packing industry.

1. How Does a Coil Upender Actually Improve Workshop Safety?

Leading Paragraph:

Imagine this scenario: your team needs to flip a 5-ton steel coil for proper packaging. Currently, they're using chains, forklifts, and manual labor - a recipe for disaster. I've seen too many factories where this process results in crushed limbs, back injuries, or worse. The coil upender solves this by taking human workers completely out of the danger zone.

Snippet Paragraph:

Coil upenders improve safety through three main mechanisms: remote operation keeps workers away from moving loads, controlled hydraulic rotation prevents sudden movements, and safety interlocks ensure proper positioning before operation. According to Randal Liu, SHJLPACK's founder, "Proper upender design can reduce coil handling injuries by 80% in heavy manufacturing environments."

Dive Deeper Content:

Key Safety Mechanisms in Modern Coil Upenders

Modern heavy-duty upenders incorporate multiple safety layers that work together to protect your workforce:

⚡ Engineering Controls

- Remote Control Operation: Operators can control the entire flipping process from a safe distance of 3-5 meters

- Emergency Stop Systems: Multiple emergency stop buttons positioned around the equipment

- Load Sensors: Detect improper weight distribution that could cause instability

- Hydraulic Safety Valves: Prevent sudden drops or uncontrolled movements

🏭 Workplace Safety Integration

- Safety Perimeter Zones: Clearly marked areas where personnel cannot enter during operation

- Automatic Lockout Systems: Prevent operation when safety gates are open

- Warning Lights and Alarms: Visual and auditory signals during machine movement

- Anti-Crush Protection: Sensors that stop operation if objects enter the danger zone

Safety Performance Comparison: Manual vs Automated Handling

| Safety Metric | Manual Handling | With Coil Upender | Improvement |

|---|---|---|---|

| Worker Injury Rate | 12-15% annually | 2-3% annually | 80% reduction |

| Near-Miss Incidents | 8-10 monthly | 1-2 monthly | 85% reduction |

| Worker Compensation Claims | $45,000/year | $8,000/year | 82% savings |

| Production Stoppages | 15-20 hours/month | 2-3 hours/month | 85% reduction |

| Safety Compliance Score | 65-75% | 95-98% | 30+ point increase |

Implementation Steps for Maximum Safety

Based on my experience helping factories in Mexico and Latin America, here's the optimal approach:

-

📋 Safety Assessment (Week 1-2)

- Evaluate current coil handling procedures

- Identify specific risk areas in your workflow

- Document near-miss incidents and injury history

-

🔧 Equipment Selection (Week 3-4)

- Choose upender with appropriate safety features for your coil sizes

- Verify CE certification and local Mexican safety standards compliance

- Ensure proper capacity margin (select equipment rated for 20% above your heaviest coils)

-

👷 Team Training (Week 5-6)

- Conduct hands-on operation training

- Establish clear safety protocols

- Implement regular safety refresher courses

-

📊 Continuous Monitoring (Ongoing)

- Track safety performance metrics

- Conduct monthly safety audits

- Maintain equipment according to manufacturer specifications

The transformation I've witnessed in Mexican steel plants after implementing proper coil upenders is remarkable. One client in Monterrey reduced their safety incidents from 7 per month to just 1 within the first quarter, while simultaneously increasing their packing line output by 35%.

2. What Are the 5 Key Features to Look for in a Heavy-Duty Coil Upender?

Leading Paragraph:

When you're investing in coil handling equipment, not all upenders are created equal. I've seen factories make the mistake of choosing based on price alone, only to face constant breakdowns and safety issues. Your heavy-duty upender needs to withstand the demanding environment of a metal processing plant while delivering reliable performance day after day.

Snippet Paragraph:

The five critical features for heavy-duty coil upenders are: robust hydraulic system with safety valves, adequate capacity rating with safety margin, programmable logic controller (PLC) with safety interlocks, durable construction with wear-resistant materials, and comprehensive safety systems including emergency stops and warning devices. These ensure reliable operation in demanding industrial environments.

Dive Deeper Content:

Essential Feature Breakdown for Mexican Factories

Having supplied equipment to numerous plants across Mexico, I've identified the features that truly matter in our region's specific operating conditions:

🔧 1. Hydraulic System Reliability

The heart of any quality upender is its hydraulic system. Look for:

- Pressure-compensated pumps that maintain consistent performance

- Proportional valves for smooth, controlled movement

- Temperature control systems to handle Mexico's varying climate conditions

- Filtration systems that protect against contamination (critical in dusty metalworking environments)

Technical Specifications to Verify:

- Operating pressure: 210-250 bar

- Oil capacity: 100-200 liters depending on model

- Cooling system: Air or water-cooled based on your ambient temperature

- Filtration level: 10 micron absolute minimum

⚡ 2. Control System Intelligence

Modern upenders should feature smart controls that prevent operator errors:

- PLC with touchscreen interface for easy operation

- Multiple operation modes (manual, semi-auto, full-auto)

- Fault diagnostics that display error messages in clear language

- Password protection for parameter changes to prevent unauthorized adjustments

🏭 3. Structural Durability

Your upender must handle daily abuse in a metal processing environment:

- Frame construction: Minimum 8mm steel plate for main structure

- Wear surfaces: Hardened steel or replaceable wear plates at contact points

- Corrosion protection: Epoxy paint or better for humidity resistance

- Bearing selection: SKF or equivalent quality for rotating components

Capacity Selection Guide for Mexican Plants

| Coil Weight Range | Recommended Upender Capacity | SHJLPACK Model | Power Requirement | Floor Space Needed |

|---|---|---|---|---|

| 1-3 tons | 5 tons | CU-5000 | 7.5 kW | 3.5m × 2.5m |

| 3-8 tons | 10 tons | CU-10000 | 15 kW | 4.5m × 3.0m |

| 8-15 tons | 20 tons | CU-20000 | 22 kW | 5.5m × 3.5m |

| 15-25 tons | 30 tons | CU-30000 | 30 kW | 6.5m × 4.0m |

Pro Tip from Randal: "Always select an upender with at least 25% more capacity than your heaviest regular coils. This safety margin ensures longer equipment life and handles occasional overweight coils without stress."

🔒 4. Safety System Completeness

Don't compromise on these safety elements:

- Dual emergency stop circuits (hardwired + software)

- Safety light curtains or pressure mats around the operation area

- Load moment indicators that warn of unstable conditions

- Mechanical safety locks for maintenance mode

🛠️ 5. Serviceability and Support

Given the geographic challenges in Mexico, serviceability is crucial:

- Modular design for easy component replacement

- Local technical support availability

- Spare parts inventory within Mexico

- Training documentation in Spanish for your maintenance team

The SHJLPACK upenders we provide include all these features as standard, while some competitors treat them as expensive options. This comprehensive approach has helped our clients in Guadalajara and Monterrey achieve 99% equipment availability rates.

3. How Much Can You Actually Save with Automated Coil Handling?

Leading Paragraph:

Many plant managers focus on the upfront cost of equipment without calculating the true total cost of ownership. I've analyzed dozens of coil packing operations, and the financial impact of manual handling goes far beyond just labor costs. When you factor in injury-related expenses, product damage, and production delays, the ROI for automation becomes undeniable.

Snippet Paragraph:

Automated coil handling typically delivers 12-24 month ROI through labor reduction (saving 3-4 workers per shift), injury cost elimination (saving $30,000-$50,000 annually), damage reduction (saving 2-3% of product value), and efficiency gains (20-35% faster processing). Most Mexican plants recover their investment in under 18 months.

Dive Deeper Content:

Detailed Cost-Benefit Analysis for Mexican Operations

Let me break down the real savings I've documented for plants similar to yours across Mexico:

💰 Direct Labor Cost Reduction

Current Manual Operation (per shift):

- 4 workers for coil handling @ $1,800 MXN daily = $7,200 MXN

- 1 supervisor @ $2,500 MXN daily

- Total labor cost per shift: $9,700 MXN

With Automated Upender (per shift):

- 1 operator @ $2,000 MXN daily

- Total labor cost per shift: $2,000 MXN

- Daily savings per shift: $7,700 MXN

Annual Savings (2 shifts, 300 days):

- $7,700 × 2 shifts × 300 days = $4,620,000 MXN (~$230,000 USD)

🏥 Injury Cost Elimination

Typical annual costs for manual coil handling:

- Worker compensation claims: $15,000-$25,000 USD

- Insurance premium increases: $8,000-$12,000 USD

- Production downtime from incidents: $10,000-$18,000 USD

- Training replacement workers: $5,000-$8,000 USD

- Total avoidable costs: $38,000-$63,000 USD annually

📦 Product Damage Reduction

Manual handling typically causes:

- 2-3% coil edge damage requiring rework

- 1-2% cosmetic damage affecting customer satisfaction

- 0.5-1% scrap from dropped coils

Value preservation for typical $500,000 USD monthly production:

- $10,000-$15,000 USD monthly damage avoidance

- $120,000-$180,000 USD annual savings

ROI Calculation Table

| Cost Category | Manual Handling (Annual) | With Upender (Annual) | Annual Savings |

|---|---|---|---|

| Labor Costs | $460,000 USD | $95,000 USD | $365,000 USD |

| Injury Costs | $50,000 USD | $8,000 USD | $42,000 USD |

| Product Damage | $150,000 USD | $25,000 USD | $125,000 USD |

| Efficiency Losses | $75,000 USD | $15,000 USD | $60,000 USD |

| Total | $735,000 USD | $143,000 USD | $592,000 USD |

Typical Upender Investment: $85,000-$150,000 USD

ROI Period: 8-15 months

Real-World Case Study: Mexican Steel Processor

🏭 Medium-sized steel service center in Puebla

- Challenge: Manual coil handling with 12 injury incidents annually, 65% packing line efficiency, high labor turnover

- Solution: SHJLPACK 15-ton capacity upender with automated positioning

- Results:

- Labor reduced from 9 to 3 workers per day

- Injuries dropped to 1 minor incident annually

- Packing efficiency increased to 92%

- ROI achieved in 11 months

- Product damage reduced from 3.2% to 0.4%

As Randal often emphasizes: "The safest equipment is also the most profitable in the long run. Proper automation pays for itself while protecting your most valuable asset - your people."

4. Which Coil Upender Brands Offer the Best Value for Mexican Factories?

Leading Paragraph:

Choosing the right equipment supplier is as important as choosing the right equipment. I've worked with virtually every major player in the coil handling market, and I've seen how the wrong choice can lead to endless headaches with service delays, parts availability, and technical support. For Mexican factories, you need suppliers who understand our specific challenges and can provide reliable local support.

Snippet Paragraph:

For Mexican factories, SHJLPACK offers the best overall value with local technical support, followed by 风鼎 (Fhopepack) for budget-conscious operations, and 无锡步惠 for basic applications. Key selection criteria should include: local service presence, spare parts availability, training in Spanish, and understanding of Mexican safety standards (NOM).

Dive Deeper Content:

Comprehensive Brand Analysis for Latin American Markets

Based on my two decades of experience and feedback from numerous clients throughout Mexico, here's my honest assessment:

🥇 SHJLPACK - Premium Value Choice

Strengths:

- Local Mexican technical team with 48-hour response time

- Spanish-language documentation and training materials

- Spare parts inventory maintained in Monterrey and Guadalajara

- Custom engineering for specific Mexican factory layouts

- Comprehensive warranty with on-site service included

Ideal For:

- Plants running 2-3 shifts daily

- Operations requiring high equipment availability (>95%)

- Companies prioritizing safety and long-term reliability

- Factories with limited maintenance resources

Investment Range: $90,000-$160,000 USD depending on capacity

🥈 风鼎 (Fhopepack) - Budget Alternative

Strengths:

- Competitive pricing (20-30% lower than premium brands)

- Adequate performance for light to medium duty applications

- Standard models available with shorter delivery times

Considerations:

- Limited local technical support in Mexico

- Longer spare parts lead times (4-6 weeks from China)

- Basic training materials, primarily in English

- May require additional safety modifications for Mexican standards

Best Suited For:

- Single-shift operations

- Factories with strong in-house maintenance teams

- Budget-constrained operations with lighter usage requirements

Investment Range: $65,000-$120,000 USD

🥉 无锡步惠 - Economy Option

Strengths:

- Lowest initial cost in the market

- Simple mechanical designs easier for basic repairs

- Availability of entry-level models

Important Limitations:

- Minimal local support presence in Mexico

- Limited capacity for heavy-duty applications

- Basic safety features may need upgrading

- Higher long-term maintenance costs

Appropriate For:

- Very light usage applications (under 10 cycles per day)

- Operations with full-time mechanical maintenance staff

- Temporary or seasonal production needs

Investment Range: $45,000-$80,000 USD

Decision Matrix for Mexican Plant Managers

| Selection Factor | SHJLPACK | 风鼎 (Fhopepack) | 无锡步惠 |

|---|---|---|---|

| Local Technical Support | ✅ Excellent (Mexico-based) | 🟡 Limited (Regional) | ❌ Minimal |

| Spare Parts Availability | ✅ 3-5 days | 🟡 4-6 weeks | ❌ 6-8 weeks |

| Spanish Documentation | ✅ Complete | 🟡 Basic English | ❌ Chinese/English |

| NOM Standards Compliance | ✅ Fully Certified | 🟡 Partial Compliance | 🟡 May Need Modifications |

| Training Quality | ✅ On-site Spanish | 🟡 Remote English | ❌ Self-study |

| Long-term Reliability | ✅ 95%+ Uptime | 🟡 85-90% Uptime | 🟡 75-85% Uptime |

| Total Cost of Ownership | ✅ Lowest 5-year | 🟡 Medium 5-year | ❌ Highest 5-year |

Critical Service Considerations for Mexico

From helping numerous factories navigate equipment selection, here are the service-related factors that matter most:

🌎 Geographic Support Coverage

- Verify the supplier has technicians within reasonable distance of your plant

- Check response time commitments for emergency repairs

- Confirm availability of loaner equipment during extended repairs

💬 Language and Communication

- Ensure technical documentation available in Spanish

- Verify 24/7 support hotline with Spanish-speaking engineers

- Confirm training conducted in Spanish by experienced instructors

🛠️ Parts and Maintenance

- Check local inventory of common wear parts

- Verify reasonable pricing for replacement components

- Confirm preventive maintenance program availability

As Randal