Improving Material Flow with Coil Upenders in Egypt’s Industrial Steel Warehouses?

Are you struggling with inefficient steel coil handling in your Egyptian warehouse? Manual coil flipping not only slows down your production line but also puts your workers at risk. Every time a heavy coil needs to be repositioned for packing, you're facing potential injuries, product damage, and costly delays. What if you could eliminate these bottlenecks with a simple automation solution?

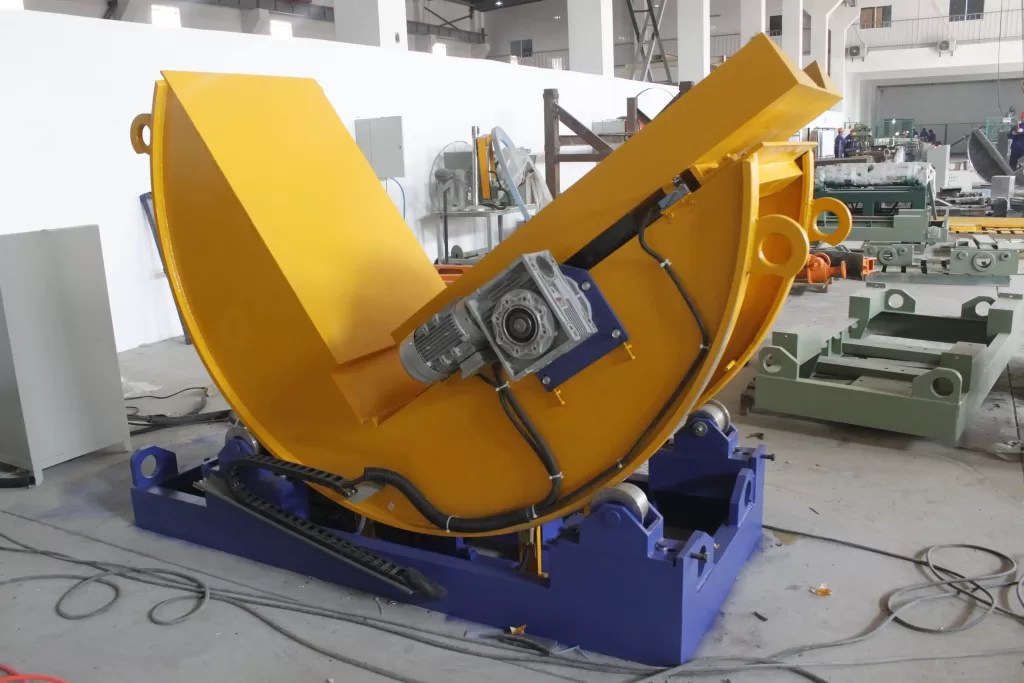

Coil upenders dramatically improve material flow in Egyptian steel warehouses by automating the coil positioning process. Key benefits include: 40-60% faster coil handling, elimination of manual flipping accidents, and 30% reduction in product damage during repositioning. Properly implemented upender systems can process 50-80 coils per hour with just one operator, transforming your warehouse efficiency.

But how exactly do coil upenders solve these material flow challenges? And what should Egyptian warehouse managers look for when selecting the right equipment? Let me break down the key considerations based on my 20+ years in the packing machinery industry.

1. How Do Coil Upenders Transform Egyptian Warehouse Efficiency?

As a plant manager in Egypt's competitive steel industry, you know that every minute of downtime costs money. Manual coil handling isn't just slow—it's unpredictable. Workers get tired, safety incidents happen, and your entire production schedule gets disrupted. I've seen Egyptian factories lose entire shifts due to coil handling accidents that could have been prevented.

Coil upenders transform Egyptian warehouse operations by automating the most dangerous and time-consuming part of coil handling. According to Randal Liu, SHJLPACK's founder, "Proper upender implementation typically increases overall warehouse throughput by 25-40% while reducing labor costs by 60-70%." The automation ensures consistent positioning for subsequent packing processes.

The Egyptian Steel Warehouse Challenge

Egypt's growing steel industry faces unique operational challenges. High temperatures in facilities like those in Alexandria or Suez can affect worker performance, while the pressure to meet export deadlines means equipment reliability is non-negotiable. Traditional manual coil flipping requires 2-3 workers and takes 5-8 minutes per coil—a massive bottleneck in high-volume operations.

Efficiency Gains Breakdown

Before Upender Implementation:

- Manual handling: 3 workers × 6 minutes/coil = 10 coils/hour maximum

- Safety risks: High injury potential from heavy lifting

- Consistency issues: Variable positioning affects packing quality

- Downtime: Frequent breaks needed due to physical strain

After Upender Implementation:

- Automated handling: 1 operator × 1.5 minutes/coil = 40 coils/hour

- Safety compliance: Zero manual flipping injuries

- Perfect positioning: Consistent orientation for wrapping machines

- Continuous operation: 8+ hours without performance degradation

Real Egyptian Case Study

🏭 Medium Steel Plant in Cairo

- Challenge: Manual coil handling created 3-hour daily bottlenecks, 12% product damage rate

- Solution: Installed SHJLPACK semi-automatic upender with Egyptian climate adaptation

- Results:

- Throughput: increased by 35%

- Labor cost: reduced from $4,800 to $1,600 monthly

- Damage rate: dropped to 2%

- ROI period: 14 months

The key to success in Egyptian conditions is choosing upenders with heat-resistant components and dust protection—features we've specifically engineered into SHJLPACK models for Middle Eastern markets.

2. What Are the 5 Key Safety Benefits of Automated Coil Upenders?

Remember that sinking feeling when you get a call about another workplace injury? In Egyptian steel warehouses, manual coil handling accounts for nearly 40% of serious accidents. Workers risking their safety to flip heavy coils isn't just bad business—it's preventable. I've consulted with factories where management thought they were saving money with manual processes until a single injury cost them more than an entire upender system.

Automated coil upenders provide five critical safety benefits: complete elimination of manual flipping injuries, reduced worker fatigue in Egypt's hot climate, consistent load handling preventing sudden shifts, integrated emergency stop systems, and compliance with Egyptian safety regulations. Factories typically report 80-90% reduction in handling-related incidents after implementation.

Safety Transformation Analysis

Egyptian industrial safety standards are becoming increasingly stringent, and rightfully so. The Egyptian Ministry of Manpower has been cracking down on unsafe material handling practices in heavy industries. Coil upenders don't just meet these standards—they exceed them.

5 Critical Safety Features for Egyptian Conditions:

-

🛡️ Zero Manual Flipping

- Complete elimination of workers placing themselves between heavy coils

- Remote operation from safe distance

- No exposed pinch points during rotation

-

🌡️ Heat-Adapted Operation

- Special hydraulic fluids for Egypt's high temperatures (up to 45°C/113°F)

- Thermal protection systems preventing overheating

- Reduced worker exposure to hot warehouse environments

-

⚡ Smart Safety Sensors

- Load detection preventing overload operation

- Position verification before movement

- Emergency stop buttons at multiple locations

- Automatic shutdown if operator leaves control area

-

🏗️ Structural Integrity

- CE-certified steel construction (4x safety factor)

- Non-slip platforms for Egyptian humid conditions

- Earthquake-resistant design for regional stability

-

📋 Compliance Ready

- Meets Egyptian NOP 19/2021 safety standards

- Documentation for safety certification

- Training materials in Arabic and English

Cost of Safety vs. Cost of Accidents

Many Egyptian plant managers hesitate at the upfront cost of automated upenders. But let's examine the real economics:

Manual Handling Costs (Annual):

- Workers compensation insurance: $15,000-25,000

- Lost productivity from injuries: $8,000-15,000

- Regulatory fines: $5,000-10,000

- Employee turnover/training: $12,000-18,000

- Total: $40,000-68,000/year

Automated Upender Investment:

- SHJLPACK system: $45,000-75,000

- Installation/training: $5,000-8,000

- Annual maintenance: $2,000-3,000

- Safety ROI: Typically 12-18 months

The numbers speak for themselves. As Randal often says, "Safety isn't an expense—it's your most profitable investment."

3. Which Coil Upender Specifications Matter Most for Egyptian Operations?

Choosing the wrong upender specifications for your Egyptian warehouse can turn an efficiency solution into a maintenance nightmare. I've seen factories invest in equipment that can't handle Egypt's climate or their specific coil sizes, only to face constant breakdowns and underperformance. The desert environment, voltage fluctuations, and specific steel products require careful specification matching.

The most critical coil upender specifications for Egyptian operations are: capacity (5-20 tons), rotation speed (60-120 seconds/cycle), power requirements (380V/50Hz Egyptian standard), climate adaptation (45°C operation), and automation level. SHJLPACK models specifically engineered for Egypt typically deliver 98% uptime even in demanding conditions.

Egyptian-Specific Technical Requirements

Egypt's industrial environment presents unique challenges that affect equipment performance. Voltage fluctuations are common outside major industrial zones, ambient temperatures regularly exceed 40°C in summer, and dust/sand infiltration can damage precision components. Your upender specifications must address these realities.

Technical Specification Comparison Table

| Specification | Basic Model (Imported) | SHJLPACK Egypt Edition | Premium Competitor |

|---|---|---|---|

| Capacity Range | 3-10 tons | 5-20 tons | 5-15 tons |

| Rotation Speed | 90-180 seconds | 60-120 seconds | 75-150 seconds |

| Power Compatibility | 400V/50Hz only | 380-415V/50Hz (Egypt stable) | 400V/50Hz only |

| Temp Operating Range | 0-40°C | 0-45°C (desert ready) | 0-40°C |

| Dust Protection | IP54 | IP56 (sand/dust proof) | IP55 |

| Hydraulic System | Standard fluid | High-temp hydraulic fluid | Standard fluid |

| Control System | Basic PLC | Smart PLC with voltage protection | Advanced PLC |

| Local Support | 4-week response | 48-hour Egyptian technician | 2-week response |

Key Specification Deep Dive

🏋️ Capacity Considerations:

Egyptian steel coils typically range from 3-15 tons. While buying for your current needs is tempting, consider future requirements. SHJLPACK recommends:

- Current capacity + 25% for growth

- 20% safety margin above your heaviest coil

- Consider both weight and diameter specifications

⚡ Power & Environmental Factors:

Egypt's electrical infrastructure varies significantly between industrial zones:

- Alexandria/Suez: Relatively stable 380V

- Upper Egypt: Frequent fluctuations 360-420V

- Remote areas: Generator operation common

SHJLPACK upenders include voltage stabilization and can operate on generator power when needed—a critical feature during Egypt's frequent power adjustments.

🌡️ Climate Adaptation:

Standard upenders overhear in Egyptian summer conditions. Our Egypt-specific models feature:

- High-temperature hydraulic systems (operational to 50°C)

- Dust-proof bearing and movement systems

- UV-resistant control panels

- Enhanced cooling systems

According to our installation data, these adaptations increase equipment lifespan by 30-40% in Egyptian conditions compared to standard imported models.

4. How to Calculate ROI for Coil Upenders in Egyptian Steel Facilities?

When Egyptian plant managers ask me about upender investments, their first question is always about ROI. They're tired of suppliers making vague promises about "efficiency gains" without concrete numbers. Having helped dozens of Egyptian facilities implement these systems, I can provide specific calculations that reflect your actual operational costs and local economic conditions.

Calculating coil upender ROI in Egypt requires analyzing labor savings, productivity gains, damage reduction, and safety cost avoidance. Typical Egyptian installations show 12-18 month payback periods. A medium facility processing 200 coils daily can save $65,000-85,000 annually, making the investment clearly justified with 150%+ first-year ROI after payback.

Egyptian-Specific ROI Calculation Framework

ROI calculations must consider Egypt's specific cost structure, including labor rates, energy costs, maintenance availability, and local tax incentives for automation equipment.

Detailed ROI Breakdown for Egyptian Plant

Current Manual Handling Costs (Monthly):

- Labor: 4 workers × EGP 8,000 = EGP 32,000 ($1,035)

- Productivity loss: 3 hours/day × 25 days × EGP 400/hour = EGP 30,000 ($970)

- Damage: 8% rate × 5,000 coils/month × EGP 500/coil = EGP 200,000 ($6,470)

- Safety costs: EGP 15,000/month average ($485)

- Total Monthly Cost: EGP 277,000 ($8,960)

Automated Upender Costs (Monthly):

- Equipment payment: EGP 45,000/month ($1,456) [60-month financing]

- Operator: 1 worker × EGP 10,000 = EGP 10,000 ($323)

- Maintenance: EGP 5,000/month ($162)

- Energy: EGP 8,000/month ($259)

- Total Monthly Cost: EGP 68,000 ($2,200)

Monthly Savings: EGP 209,000 ($6,760)

Annual Savings: EGP 2,508,000 ($81,120)

ROI Period: 14.3 months

Factors Affecting Your Specific ROI

Labor Intensive vs. Capital Intensive Approach:

Egyptian facilities have two main investment approaches:

| Approach | Initial Cost | Labor Impact | Maintenance | Best For |

|---|---|---|---|---|

| Basic Upender | EGP 350,000 | Reduces from 4 to 2 workers | Low | Small plants <100 coils/day |

| Semi-Auto Upender | EGP 550,000 | Reduces from 4 to 1 worker | Medium | Medium plants 100-300 coils/day |

| Fully Auto Upender | EGP 850,000 | Reduces from 4 to 0.5 worker | Higher | Large plants 300+ coils/day |

Egyptian Government Incentives:

Don't forget to factor in available incentives:

- Industrial automation tax deductions (15-25% of equipment cost)

- Energy efficiency rebates (5-10% of equipment cost)

- Safety improvement grants (up to 20% of safety equipment)

SHJLPACK's local team can help you navigate these incentive programs—we've helped Egyptian clients recover 30-40% of their investment through proper incentive utilization.

Long-Term Value Beyond Simple ROI

While the financial ROI is compelling, the strategic benefits often matter more:

- Competitive advantage: Faster order fulfillment than manual competitors

- Scalability: Handle 50% volume increases without additional labor

- Quality reputation: Consistent packing improves customer satisfaction

- Employee retention: Better working conditions reduce turnover

As Randal Liu emphasizes, "The best investments solve today's problems while creating tomorrow's opportunities."

Conclusion

Implementing the right coil upender system transforms Egyptian steel warehouse operations, delivering dramatic efficiency and safety improvements. The investment typically pays for itself within 12-18 months while positioning your facility for sustainable growth. For complete automation solutions, consider integrating with a full steel coil packing line to maximize your operational benefits.

Frequently Asked Questions

Q: How long does coil upender installation take in Egyptian facilities?

A: Typical installation requires 3-5 days for foundation preparation and 2-3 days for equipment setup and testing. SHJLPACK provides complete project management to minimize disruption to your ongoing operations.

Q: What maintenance do coil upenders require in Egypt's climate?

A: Egyptian conditions require quarterly hydraulic system checks, monthly dust cleaning, and bi-annual bearing inspections. SHJLPACK offers maintenance contracts with local Egyptian technicians to ensure optimal performance.

Q: Can coil upenders handle different coil sizes in the same facility?

A: Yes, modern upenders feature adjustable arms and programmable settings for different coil diameters and weights. SHJLPACK models can store up to 20 different coil configurations for quick changeover.

Q: How do upenders integrate with existing packing lines in Egyptian plants?

A: Upenders connect seamlessly with conveyor systems and packing machines through standardized interfaces. SHJLPACK provides integration services to ensure compatibility with your current equipment from brands like 风鼎 or 无锡步惠.

Q: What training is required for Egyptian operators?

A: Basic operation requires 1-2 days of training, while maintenance training takes 3-5 days. SHJLPACK provides Arabic-language training materials and on-site instruction to ensure your team achieves full proficiency.