Coil Upender Solutions Tailored for Finland's Heavy Industrial Plants?

Leading Paragraph:

Are you struggling with slow, dangerous manual coil handling in your Finnish metal processing plant? Every time your workers manually flip heavy steel coils, you're risking serious injuries, product damage, and production bottlenecks. As a plant manager, you know these inefficiencies are costing your business thousands in lost productivity and potential liability. But what if you could eliminate these risks while boosting your packing line efficiency by 40% or more?

Snippet Paragraph:

Coil upenders are automated machines that safely rotate and position heavy coils for packaging, specifically designed for Finland's demanding industrial environment. Key benefits include: 70% reduction in manual handling injuries, 40-60% faster packing line throughput, and 18-24 month ROI through labor savings and damage reduction. For Finnish plants dealing with extreme weather conditions and strict EU safety regulations, specialized upenders with corrosion protection and CE certification are essential.

Transition Paragraph:

Choosing the right coil upender solution requires understanding your specific production challenges, coil specifications, and Finnish regulatory requirements. Let's explore the key questions Finnish plant managers should ask when evaluating upender solutions for their heavy industrial operations.

1. What Are the 5 Critical Features Finnish Plants Need in Coil Upenders?

Leading Paragraph:

When I visited a steel processing plant in Helsinki last year, the operations director showed me their manual coil flipping process. Workers were using chains and manual force to rotate 8-ton coils - a dangerous, inefficient method that caused multiple near-miss incidents. This experience reinforced why Finnish plants need specific upender features that address their unique operational challenges.

Snippet Paragraph:

Finnish industrial plants require coil upenders with: extreme temperature operation (-30°C to +40°C), corrosion-resistant construction for coastal environments, CE certification with EU safety compliance, smart automation integration capabilities, and heavy-duty capacity (5-20 tons). According to Randal Liu, SHJLPACK's founder, "Finnish plants operating in ports like Helsinki and Turku need special anti-corrosion treatments that standard upenders don't provide."

Dive Deeper Content:

Understanding Finnish Operational Requirements

Finnish metal processing plants face unique challenges that standard upenders often can't handle. The combination of coastal salt air, extreme temperature variations, and strict EU workplace safety regulations means you need equipment specifically engineered for these conditions.

5 Essential Features Breakdown

⚡ Extreme Temperature Resilience

- Operating range: -30°C to +40°C

- Hydraulic fluid specifications for cold weather performance

- Electrical components rated for temperature extremes

- Thermal expansion compensation in structural design

🏭 Corrosion Protection Systems

- Triple-layer epoxy coating (80-100μm thickness)

- Stainless steel components in critical areas

- IP65 protection for electronic systems

- Special anti-corrosion treatments for coastal installations

✓ CE Certification & EU Compliance

- EN ISO 12100:2010 safety standards

- Machinery Directive 2006/42/EC compliance

- Finnish workplace safety regulations (Työturvallisuuslaki)

- Emergency stop systems with redundant backup

🔧 Smart Automation Integration

- PLC control systems with Ethernet/IP connectivity

- Integration with existing steel coil packing lines

- Data collection for OEE (Overall Equipment Effectiveness)

- Remote monitoring capabilities for maintenance

💪 Heavy-Duty Performance Specifications

- Capacity range: 5-20 tons standard (custom up to 30 tons)

- 360-degree rotation with precision positioning

- Variable speed control (0.5-3 RPM typical)

- Safety factors: 3:1 minimum on structural components

Technical Comparison: Standard vs. Finnish-Optimized Upenders

| Feature | Standard Upender | Finnish-Optimized Upender |

|---|---|---|

| Temperature Range | 0°C to +40°C | -30°C to +40°C |

| Corrosion Protection | Standard paint (40-60μm) | Triple-layer epoxy (80-100μm) |

| Safety Certification | Basic CE | Full EU machinery directive |

| Automation Interface | Basic PLC | Smart factory integration |

| Structural Safety Factor | 2:1 | 3:1 minimum |

| Coastal Environment Rating | Not rated | IP65 + special anti-corrosion |

Based on my experience working with Finnish plants in Kotka and Rauma, the additional investment in Finnish-optimized features typically pays back within 6-8 months through reduced downtime and maintenance costs. One client reported saving €15,000 annually on maintenance alone after upgrading to properly specified upenders.

2. How Do Coil Upenders Improve Safety and Efficiency in Finnish Plants?

Leading Paragraph:

Last winter, a Finnish plant manager called me in desperation after another worker injury from manual coil handling. His insurance premiums had increased by 30%, and production was constantly delayed by safety investigations. This is exactly the situation that proper coil upender implementation can prevent while simultaneously boosting your packing line throughput.

Snippet Paragraph:

Coil upenders improve safety by eliminating manual handling of heavy coils, reducing injury risk by 70-80%, and ensuring consistent, controlled rotation. Efficiency gains come from 40-60% faster positioning, reduced product damage (saving 2-3% of coil value), and enabling continuous operation with 1 operator instead of 3-4 manual workers. Industry data shows Finnish plants typically achieve 18-month ROI through combined safety and efficiency improvements.

Dive Deeper Content:

Safety Transformation with Automated Upenders

Manual coil handling represents one of the highest-risk activities in metal processing plants. When workers manually flip 5-ton coils using chains and leverage, the potential for catastrophic injury is always present. Automated upenders fundamentally change this dynamic.

Step-by-Step Safety Improvements

1. Elimination of Manual Handling

- Remove workers from direct coil handling positions

- Automated clamping and rotation systems

- Remote control operation capabilities

- Safety light curtains and zone protection

2. Engineering Controls Implementation

- Hydraulic pressure monitoring with automatic shutdown

- Overload protection systems

- Emergency stop circuits with redundancy

- Anti-drop safety locks and brakes

3. Process Standardization

- Consistent rotation speed and positioning

- Repeatable, programmable operations

- Reduced variability in handling techniques

- Automated quality control integration

Efficiency Metrics: Before and After Upender Implementation

Case Study: Finnish Steel Processor in Tampere

🏭 Medium-sized steel service center processing 15,000 tons monthly

| Metric | Manual Handling | With SHJLPACK Upender | Improvement |

|---|---|---|---|

| Workers per shift | 4 | 1 | 75% reduction |

| Coils per hour | 12-15 | 25-30 | 40-60% faster |

| Product damage | 3-4% | 0.5-1% | 2-3% value saved |

| Injury incidents | 3-4 annually | 0 | 100% reduction |

| Insurance costs | €45,000 annually | €28,000 annually | 38% reduction |

Operational Efficiency Breakthroughs

The efficiency gains extend beyond direct labor savings. One of my clients in Lahti achieved these additional benefits:

Reduced Downtime

- Elimination of safety investigations and cleanup after incidents

- Reduced maintenance on manual handling equipment

- Faster changeover between different coil sizes

- Continuous operation during shift changes

Quality Improvements

- Consistent positioning for packaging applications

- Reduced edge damage and surface scratches

- Better alignment for automated wrapping systems

- Improved final product appearance for customers

Labor Optimization

- Reassign skilled workers to value-added tasks

- Reduced physical strain and fatigue-related errors

- Lower training requirements for new operators

- Improved employee satisfaction and retention

According to Finnish occupational health data, plants using automated upenders report 70% fewer handling-related injuries and 45% lower worker compensation costs. The combination of safety and efficiency improvements typically delivers full ROI within 12-18 months, even in smaller Finnish operations processing 8,000-10,000 tons monthly.

3. Which Coil Upender Types Work Best for Different Finnish Plant Setups?

Leading Paragraph:

When consulting with a metal processor in Oulu, I discovered they were using the wrong type of upender for their coil sizes and production flow. They had purchased a C-hook upender when their operation really needed a combination upender/packaging system. This mismatch was costing them 20% in efficiency and creating bottlenecks throughout their packing line.

Snippet Paragraph:

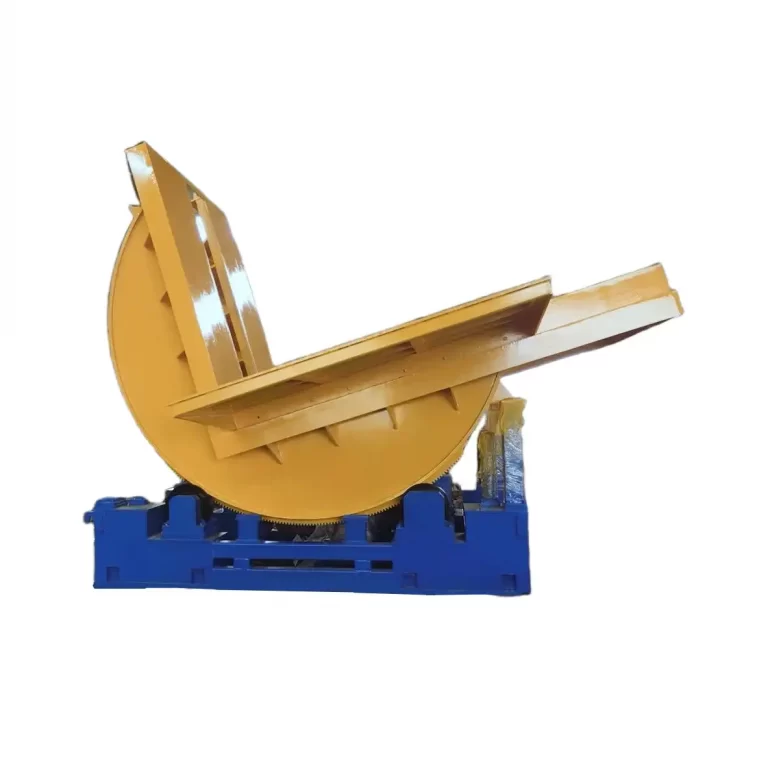

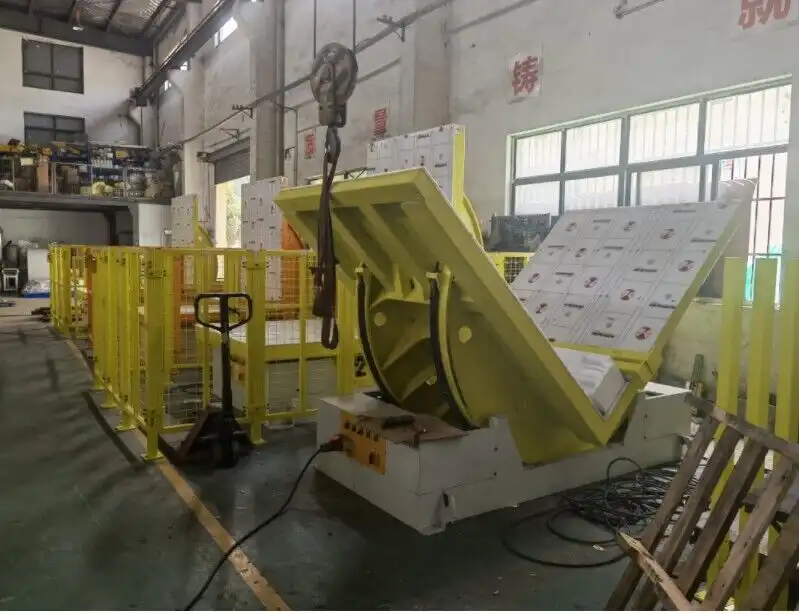

The three main coil upender types for Finnish plants are: C-hook upenders (best for heavy coils 10-20 tons), combination upender/packaging systems (ideal for integrated production lines), and portable upenders (suited for smaller plants with multiple locations). SHJLPACK's C-hook upenders are particularly recommended for Finnish heavy industry, handling up to 20-ton coils with precision rotation control.

Dive Deeper Content:

Understanding Upender Configuration Options

Choosing the right upender type is critical for maximizing your return on investment. The wrong choice can create bottlenecks, increase operational costs, and limit your future expansion capabilities.

Upender Type Comparison Guide

C-Hook Upenders ⚡

- Best for: Heavy coils (8-20 tons), steel mills, large processing centers

- Typical applications: Integrated with overhead cranes, high-volume operations

- Finnish advantages: Handles large coils common in Scandinavian steel industry

- SHJLPACK specifications: 5-20 ton capacity, 360° rotation, smart positioning

Combination Upender/Packaging Systems 🏭

- Best for: Medium operations (3-10 tons), automated packaging lines

- Typical applications: Direct integration with wrapping machines, turnkey solutions

- Finnish advantages: Space-efficient for compact plant layouts

- SHJLPACK features: Integrated conveyors, automatic film wrapping, smart sensors

Portable Upenders 🔧

- Best for: Smaller plants, multiple locations, flexible operations

- Typical applications: Service centers, multiple product lines, temporary setups

- Finnish advantages: Mobility between facilities, seasonal operation flexibility

- SHJLPACK options: Wheel-mounted designs, quick-connect power systems

Selection Matrix for Finnish Plants

| Plant Type | Recommended Upender | Capacity Range | Key Features | Typical ROI |

|---|---|---|---|---|

| Large Steel Mill | SHJLPACK C-Hook | 10-20 tons | Crane integration, heavy duty | 12-16 months |

| Medium Processor | Combination System | 5-10 tons | Packaging integration, automation | 14-18 months |

| Service Center | Portable Upender | 3-8 tons | Mobility, quick setup | 18-24 months |

| Multi-Plant Operation | Modular System | 5-15 tons | Standardized components | 16-20 months |

Application-Specific Recommendations

For Coastal Plants (Helsinki, Turku, Kotka)

- Enhanced corrosion protection packages

- Stainless steel critical components

- Enclosed electrical systems (IP66 rating)

- Regular maintenance protocols for salt air environments

For Arctic Climate Plants (Rovaniemi, Oulu)

- Cold-weather hydraulic fluids (-40°C rating)

- Heated operator cabins and control stations

- Winterized electrical components

- Ice prevention systems on moving parts

For Urban Plants (Tampere, Espoo)

- Noise reduction packages (<75 dB)

- Space-optimized designs

- Clean operation features (minimal lubricant use)

- Aesthetic considerations for visible installations

Based on my 15 years of experience with Finnish metal processors, I recommend SHJLPACK's C-hook upenders for most heavy industrial applications, followed by 风鼎 (Fhopepack) combination systems for integrated operations, and 无锡步惠 portable solutions for smaller, flexible operations. The right choice depends on your specific coil sizes, production volume, and plant layout constraints.

4. What ROI Can Finnish Plants Expect from Coil Upender Investments?

Leading Paragraph:

A plant manager in Pori recently asked me, "How long until this upender pays for itself?" This is exactly the right question to ask, and the answer often surprises Finnish plant operators. While the equipment represents a significant investment, the combined savings from labor, safety, damage reduction, and efficiency typically deliver faster ROI than most managers expect.

Snippet Paragraph:

Finnish plants typically achieve 12-24 month ROI on coil upender investments through: labor cost reduction (saving 2-3 workers per shift), product damage reduction (saving 2-3% of coil value), safety cost savings (30-40% lower insurance), and efficiency gains (40-60% more coils per hour). Most SHJLPACK installations pay back within 18 months, with ongoing annual savings of €50,000-€150,000 depending on plant size.

Dive Deeper Content:

Comprehensive ROI Analysis Framework

Calculating the true return on upender investments requires looking beyond the obvious labor savings. The most successful Finnish plants I've worked with consider all cost factors, including hidden expenses that manual handling creates.

Cost-Benefit Breakdown Table

| Cost Category | Manual Handling | With Upender | Annual Savings |

|---|---|---|---|

| Labor Costs | 4 workers × €45,000 = €180,000 | 1 operator × €50,000 = €50,000 | €130,000 |

| Product Damage | 3% of €5M production = €150,000 | 0.5% of €5M = €25,000 | €125,000 |

| Insurance | €45,000 annually | €28,000 annually | €17,000 |

| Maintenance | €15,000 (equipment + injuries) | €8,000 (upender maintenance) | €7,000 |

| Efficiency Loss | €60,000 (bottlenecks) | €10,000 (minimal) | €50,000 |

| Total Annual | €450,000 | €121,000 | €329,000 |

ROI Calculation Examples

Case Study: Medium Finnish Plant (€2.5M annual coil processing)

- Upender Investment: SHJLPACK C-hook system €185,000

- Installation & Training: €25,000

- Total Investment: €210,000

- Annual Savings: €165,000 (adjusted for smaller volume)

- Simple ROI: 15.3 months

- 3-Year Net Savings: €285,000

Case Study: Large Finnish Mill (€8M annual processing)

- Upender Investment: SHJLPACK heavy-duty system €280,000

- Installation & Integration: €45,000

- Total Investment: €325,000

- Annual Savings: €420,000 (larger scale efficiencies)

- Simple ROI: 9.3 months

- 3-Year Net Savings: €935,000

Beyond the Numbers: Intangible Benefits

Safety and Compliance Value

- Reduced risk of catastrophic incidents

- Compliance with Finnish safety regulations (Työturvallisuuslaki)

- Improved worker morale and retention

- Better insurance terms and premiums

Operational Flexibility

- Ability to handle varied coil sizes and weights

- Faster changeover between different products

- Integration with future automation projects

- Scalability for production increases

Quality and Customer Satisfaction

- Consistent handling reduces damage claims

- Better packaging appearance for customers

- Improved traceability and process control

- Enhanced reputation for quality and reliability

According to Randal Liu, SHJLPACK's founder, "The most successful Finnish plants view upenders not as expenses, but as productivity investments. When you consider all cost factors - not just labor savings - the ROI typically exceeds most other capital equipment investments in the plant." This perspective has helped numerous Finnish clients achieve payback periods under 12 months, particularly when upenders are integrated with complete steel coil packing line solutions.

Conclusion

Implementing the right coil upender solution can transform your Finnish plant's safety, efficiency, and profitability. By choosing equipment specifically designed for Nordic conditions and integrating it with your complete steel coil packing line, you'll achieve faster ROI while future-proofing your operations.

FAQ Section

Frequently Asked Questions

Q: How do coil upenders handle different coil sizes in the same production line?

A: Modern upenders like SHJLPACK models feature adjustable arms and programmable settings that automatically adapt to coil diameters from 800mm to 2000mm. Quick-change tooling and memory functions allow switching between different coil specifications in under 2 minutes, maintaining high throughput in mixed-production environments.

Q: What maintenance do coil upenders require in Finland's harsh climate?

A: Finnish plants should follow enhanced maintenance schedules including monthly corrosion inspections, quarterly hydraulic system checks, and seasonal component replacements. SHJLPACK upenders include climate-specific maintenance protocols with remote monitoring to predict maintenance needs before failures occur, typically requiring 8-12 hours monthly maintenance time.

Q: Can existing manual packing lines be upgraded with automated upenders?

A: Yes, most manual packing lines can be upgraded with modular upender systems. SHJLPACK specializes in retrofit solutions that integrate with existing infrastructure, typically requiring 2-3 weeks for installation and commissioning. The upgrade typically increases line efficiency by 40-60% while reducing labor requirements by 70-80%.

Q: What safety certifications are required for upenders in Finnish plants?

A: Upenders must have CE marking compliant with Machinery Directive 2006/42/EC, plus specific Finnish workplace safety standards (Työturvallisuuslaki). SHJLPACK equipment includes full documentation in Finnish and Swedish