Coil Upender Solutions Tailored for Finland’s Heavy Industrial Plants?

Leading Paragraph:

Are you struggling with slow, inefficient coil handling processes in your Finnish metal plant? Manual coil flipping not only creates dangerous bottlenecks but also exposes your workers to serious injury risks. When production delays cost thousands per hour and workplace accidents threaten your operations, you need a solution that addresses both efficiency and safety concerns head-on.

Snippet Paragraph:

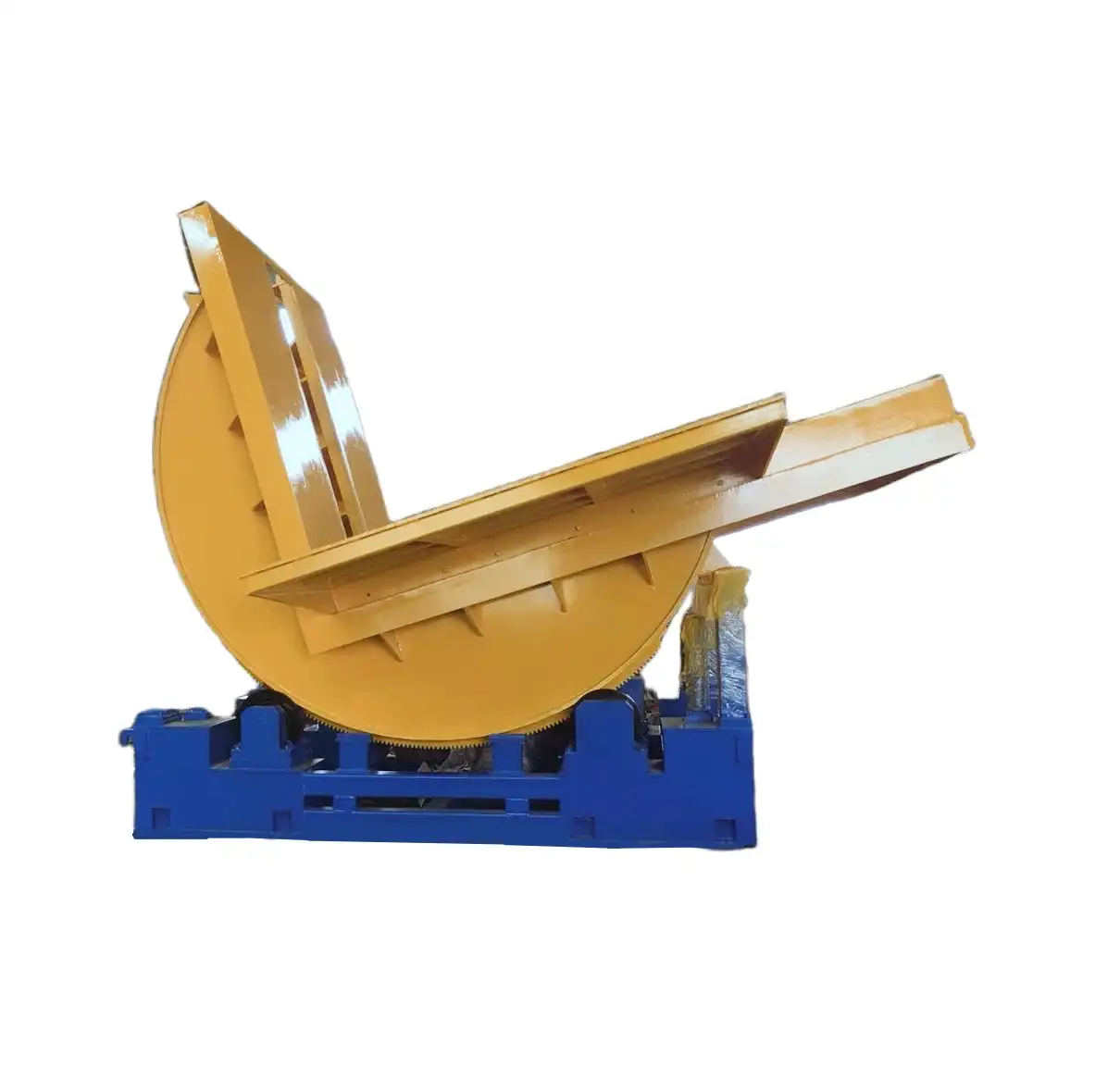

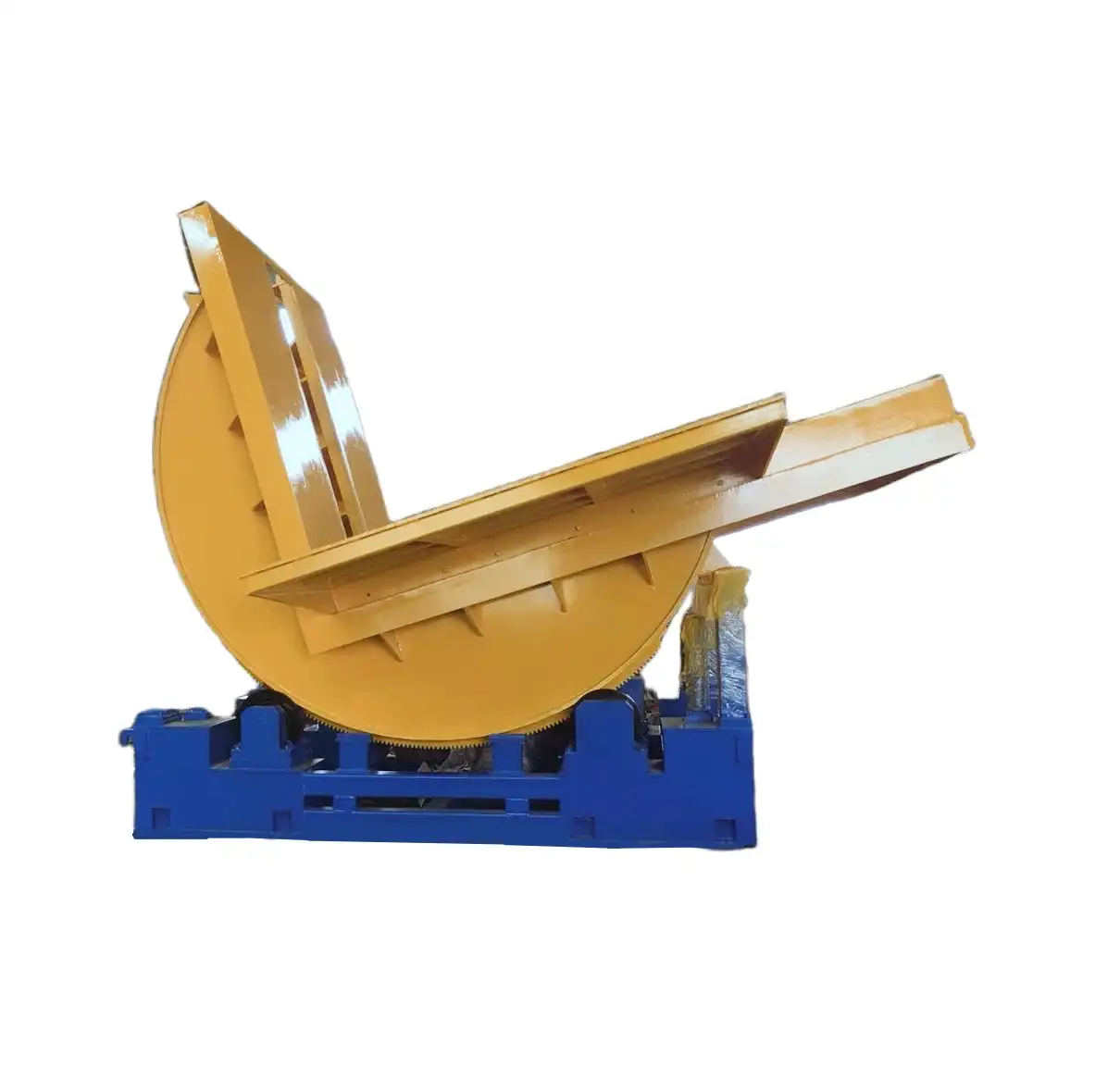

Coil upenders are specialized material handling machines that automatically rotate and reposition heavy coils for packaging and transport. For Finnish industrial plants, the right upender solution should provide: 30-50% faster coil handling than manual methods, enhanced worker safety through automated operation, and robust construction for harsh Nordic industrial environments.

Transition Paragraph:

Choosing the right coil upender involves understanding several critical factors that affect your plant's specific operational needs. Let's explore the key questions Finnish plant managers should ask when selecting upender equipment for their facilities.

1. What Are the 5 Critical Features Finnish Plants Need in Coil Upenders?

Leading Paragraph:

As a plant manager in Finland's demanding industrial sector, you face unique challenges that require specialized equipment solutions. The extreme weather conditions, high labor costs, and strict safety regulations mean your coil upenders must perform reliably under pressure while delivering clear operational benefits.

Snippet Paragraph:

Finnish industrial plants require coil upenders with: Arctic-grade construction for -30°C operation, CE certification for EU compliance, 10-20 ton capacity for heavy coils, smart automation interfaces, and energy-efficient hydraulic systems. According to Randal Liu, "Plants in Scandinavia need equipment that withstands both heavy use and harsh climates while maintaining precision."

Dive Deeper Content:

Technical Specifications for Nordic Conditions

Finnish metal processing facilities operate under some of Europe's most challenging industrial conditions. The combination of extreme temperature variations, high automation standards, and stringent worker protection regulations demands equipment that exceeds typical industrial specifications.

Key Performance Requirements:

- Temperature Resilience: Operating range of -30°C to +40°C with heated hydraulic systems

- Load Capacity: 5-25 ton range with safety margin of 150% for shock loads

- Cycle Time: 45-90 seconds per coil depending on size and weight

- Power Consumption: Energy recovery systems to reduce operating costs by 15-20%

Feature Comparison: Standard vs. Finnish-Optimized Upenders

| Feature | Standard Upender | Finnish-Optimized Upender |

|---|---|---|

| Operating Temperature | -10°C to +35°C | -30°C to +40°C |

| Safety Standards | Basic CE compliance | CE + Finnish NORSOK standards |

| Control System | Basic PLC | Smart PLC with remote monitoring |

| Maintenance Interval | 500 hours | 750 hours with cold-weather lubricants |

| Corrosion Protection | Standard paint | Triple-layer epoxy for humid environments |

Implementation Strategy for Finnish Plants

Based on my experience working with Nordic metal processors, successful upender integration follows a specific pattern. First, conduct a thorough assessment of your current coil handling workflow bottlenecks. Many Finnish plants I've consulted with discover that 60-70% of their packaging delays occur during the manual flipping stage.

Second, consider the space constraints typical of Finnish industrial facilities. The compact upender designs from SHJLPACK often work well in these environments, requiring only 15-20 square meters of floor space while handling coils up to 20 tons. Third, factor in the total cost of ownership rather than just the purchase price. Finnish plants typically achieve ROI within 14-18 months through labor reduction and damage prevention.

The automation level should match your plant's technical capabilities. While fully automated upender systems offer the highest efficiency gains, semi-automated solutions from brands like 风鼎 (Fhopepack) can provide excellent results for plants transitioning from manual processes. The key is selecting equipment that your team can operate and maintain confidently in Finland's unique industrial landscape.

2. How Can Automated Coil Upenders Improve Safety in Finnish Manufacturing?

Leading Paragraph:

Every time your workers manually handle heavy coils, you're risking not just production delays but serious workplace injuries. In Finland's highly regulated industrial environment, safety incidents can lead to massive fines, production stoppages, and damaged reputation. The transition to automated coil handling isn't just about efficiency—it's about protecting your people and your business.

Snippet Paragraph:

Automated coil upenders eliminate the most dangerous aspects of manual coil handling by removing workers from direct contact with heavy loads. According to industry data, plants using automated upenders report 80-90% reduction in coil-related injuries and 60% fewer product damage incidents. SHJLPACK upenders include multiple safety sensors and emergency stop systems.

Dive Deeper Content:

Safety Hazard Analysis: Manual vs. Automated Handling

Manual coil flipping presents multiple serious risks that automated upenders systematically eliminate. Understanding these specific hazards helps justify the safety investment in proper coil handling equipment.

Manual Handling Risks Eliminated by Upenders:

- Crush Injuries: Workers positioned between coils and equipment during manual rotation

- Strain Injuries: Improper lifting techniques causing back and musculoskeletal damage

- Impact Injuries: Coils shifting unexpectedly during manual positioning

- Pinch Points: Hands and fingers trapped during manual flipping operations

Safety Feature Implementation Checklist

When evaluating coil upenders for your Finnish plant, verify these critical safety components:

✅ Multiple Emergency Stop Systems - Hard-wired stops at operator stations and remote locations

✅ Load Sensing Technology - Prevents operation with improperly positioned coils

✅ Anti-Drop Safety Locks - Mechanical locking even during hydraulic failure

✅ Safety Light Curtains - Creates protected zones around operating areas

✅ Overload Protection - Prevents damage from exceeding rated capacity

✅ Automatic Centering - Ensures balanced loads before rotation begins

Quantifying Safety Improvements

The safety benefits of automated upenders translate into measurable business advantages. Based on data from Finnish plants that have implemented SHJLPACK upender systems:

Workers' Compensation Impact:

- Average injury cost reduction: €45,000-€65,000 annually

- Insurance premium reductions: 15-25% after safety certification

- Reduced absenteeism: 3-5 fewer lost days per worker annually

Regulatory Compliance Benefits:

- 100% compliance with Finnish Työsuojelulaki (Occupational Safety Act)

- Meeting EU Machinery Directive 2006/42/EC requirements

- Simplified safety auditing and certification processes

The safety return on investment often surprises plant managers. While the equipment cost is visible upfront, the avoided costs of single serious injury can exceed the entire upender investment. Combined with the efficiency gains, the safety argument makes automated coil handling one of the most compelling upgrades for Finnish metal processing facilities concerned with both productivity and worker protection.

3. Which Coil Upender Specifications Matter Most for Heavy Industrial Applications?

Leading Paragraph:

Selecting the wrong upender specifications can leave you with equipment that either underperforms or represents overinvestment. For heavy industrial applications in Finland's metal sector, understanding which technical parameters truly impact your operations is crucial for making informed capital equipment decisions.

Snippet Paragraph:

The most critical coil upender specifications for heavy industry include: load capacity (5-25 tons), rotation speed (45-90 seconds), power requirements (15-45 kW), and control system sophistication. SHJLPACK's industrial upenders feature 20-ton capacity, 60-second cycle time, and smart PLC controls optimized for Finnish plant conditions.

Dive Deeper Content:

Technical Specification Deep Dive

Heavy industrial applications demand upenders built for continuous operation under demanding conditions. The specifications that matter most reflect this rigorous usage pattern and the specific requirements of metal processing environments.

Capacity and Performance Specifications:

- Rated Capacity: 5-25 tons with 150% safety factor for shock loads

- Rotation Angle: 90° or 180° depending on packaging requirements

- Cycle Time: 45-90 seconds for complete rotation and positioning

- Power System: 15-45 kW hydraulic systems with energy recovery

- Control Interface: Touchscreen HMI with production data tracking

Application-Based Specification Selection

| Application | Recommended Capacity | Cycle Time | Special Features |

|---|---|---|---|

| Steel Service Centers | 5-15 tons | 45-60 seconds | Quick-change adapters |

| Heavy Steel Mills | 15-25 tons | 60-90 seconds | Reinforced structure |

| Aluminum Processing | 3-10 tons | 45-75 seconds | Non-marring contact surfaces |

| Copper & Brass | 2-8 tons | 50-80 seconds | Corrosion-resistant components |

ROI Calculation: Matching Specifications to Needs

Overspecifying upender capacity represents a common—and costly—mistake. I've helped numerous Finnish plants right-size their equipment selection using this straightforward ROI analysis method:

Current Manual Handling Costs:

- Labor: 3 workers × €4,500/month × 12 months = €162,000/year

- Product Damage: 2-3% of handled value = €45,000-€75,000 annually

- Injury Costs: €25,000-€50,000 in direct and indirect costs

Automated Upender Operating Costs:

- Equipment Investment: €85,000-€150,000 (SHJLPACK range)

- Operating Cost: €15,000-€25,000 annually (power + maintenance)

- Labor: 0.5 FTE (operator oversight) = €27,000 annually

Net Annual Savings: €140,000 - €52,000 = €88,000

ROI Period: 12-20 months depending on utilization

The specification sweet spot for most Finnish metal plants falls in the 10-15 ton capacity range with semi-automated controls. This configuration handles the majority of coil sizes while maintaining flexibility for different product mixes. Brands like 无锡步惠 offer reliable options in this range, though SHJLPACK's Nordic-optimized designs typically deliver better long-term performance in Finnish operating conditions.

4. How Do You Calculate ROI When Investing in Coil Upender Automation?

Leading Paragraph:

As a plant manager, you're constantly evaluating equipment investments against competing capital demands. Understanding the true financial return of coil upender automation requires looking beyond the purchase price to capture all operational impacts—both the obvious savings and the hidden costs of maintaining manual processes.

Snippet Paragraph:

Coil upender ROI calculation should include: labor cost reduction (typically 2-3 workers), product damage decrease (2-4% savings), injury cost avoidance, and efficiency gains from faster processing. Most Finnish plants achieve full ROI within 14-20 months with proper equipment selection and implementation.

Dive Deeper Content:

Comprehensive ROI Calculation Framework

A thorough ROI analysis for coil upender automation captures both direct cost savings and qualitative benefits that impact your bottom line. This comprehensive approach ensures you're making investment decisions based on total value rather than just purchase price.

Direct Cost Savings Components:

- Labor Reduction: Typically 2-3 full-time positions eliminated

- Damage Reduction: 2-4% decrease in product damage during handling

- Efficiency Gains: 30-50% faster coil processing throughput

- Safety Cost Avoidance: Reduced workers' compensation and insurance costs

Step-by-Step ROI Calculation Process

Step 1: Document Current Costs

- Manual labor requirements (hours × wage rates)

- Current damage rates and financial impact

- Injury history and associated costs

- Production bottlenecks and their operational impact

Step 2: Estimate Automated System Benefits

- Labor requirements with automation (typically 70-80% reduction)

- Projected damage reduction (industry average: 2-4%)

- Throughput improvement (30-50% faster processing)

- Safety improvement (80-90% injury reduction)

Step 3: Calculate Investment Requirements

- Equipment cost (SHJLPACK: €85,000-€150,000)

- Installation and commissioning (10-15% of equipment cost)

- Training and implementation (5-8% of equipment cost)

- Ongoing maintenance (2-3% annually)

Step 4: Compute Payback Period

- Annual savings ÷ total investment = simple payback period

- Include time value of money for more sophisticated analysis

- Factor in equipment lifespan (typically 10-15 years)

Real-World Finnish Plant Case Study

🏭 Mid-Sized Steel Processor in Helsinki Region

- Challenge: Manual coil handling required 4 workers, caused 3% damage rate, and created 2-day packaging bottleneck

- Solution: SHJLPACK 12-ton capacity upender with semi-automated controls

- Implementation Cost: €112,000 (equipment + installation + training)

- Results:

- Labor: Reduced from 4 to 1 operator (€135,000 annual savings)

- Damage: Decreased from 3% to 0.5% (€42,000 annual savings)

- Throughput: Increased from 15 to 28 coils/hour (40% capacity increase)

- Safety: Zero coil-related injuries in first year (€28,000 cost avoidance)

- Total Annual Savings: €205,000

- ROI Period: 6.5 months

This case demonstrates how comprehensive ROI analysis reveals the true financial impact beyond simple labor reduction. The combination of direct cost savings and operational improvements creates compelling financial justification for upender automation, particularly when using reliable equipment from established suppliers like SHJLPACK that minimize downtime and maintenance requirements.

Conclusion

Implementing the right coil upender solution transforms both safety and efficiency in Finnish heavy industrial plants, delivering strong ROI through multiple operational improvements. For complete packaging line solutions, consider our integrated steel coil packing line systems.

FAQ Section

Frequently Asked Questions

Q: What maintenance do coil upenders require in cold Finnish climates?

A: Nordic operations need cold-weather hydraulic fluids, heated reservoirs, and more frequent lubrication intervals (every 500 hours instead of 750). SHJLPACK upenders include Arctic-grade components specifically for Scandinavian conditions.

Q: How long does upender installation typically take in operating plants?

A: Most installations require 3-5 days for foundation work, 2-3 days for equipment placement, and 2 days for commissioning and training. Proper planning minimizes production disruption during implementation.

Q: Can upenders handle different coil sizes without manual adjustment?

A: Advanced models from SHJLPACK feature automatic width adjustment for coils from 800mm to 2,000mm diameter. Quick-change adapters further reduce changeover time between different product sizes.

Q: What training do operators need for automated upender systems?

A: Basic operation requires 1-2 days training, while maintenance technicians need 3-5 days. SHJLPACK provides comprehensive training in English or Finnish with local technical support availability.

Q: How do upenders integrate with existing packaging and material handling systems?

A: Modern upenders feature standardized interfaces (Ethernet/IP, Profinet) for seamless integration with conveyors, wrappers, and plant ERP systems. Compatibility verification should occur during the selection process.