Coil Upender Optimization for Indonesia's Coil Recoiling and Processing Lines?

Are you struggling with production bottlenecks in your Indonesian steel processing plant? When your coil upender equipment fails to keep pace with recoiling lines, it creates costly delays that ripple through your entire operation. Manual handling of heavy coils not only slows down production but puts your workers at serious risk. The constant flipping and positioning of coils becomes the weakest link in an otherwise efficient processing line.

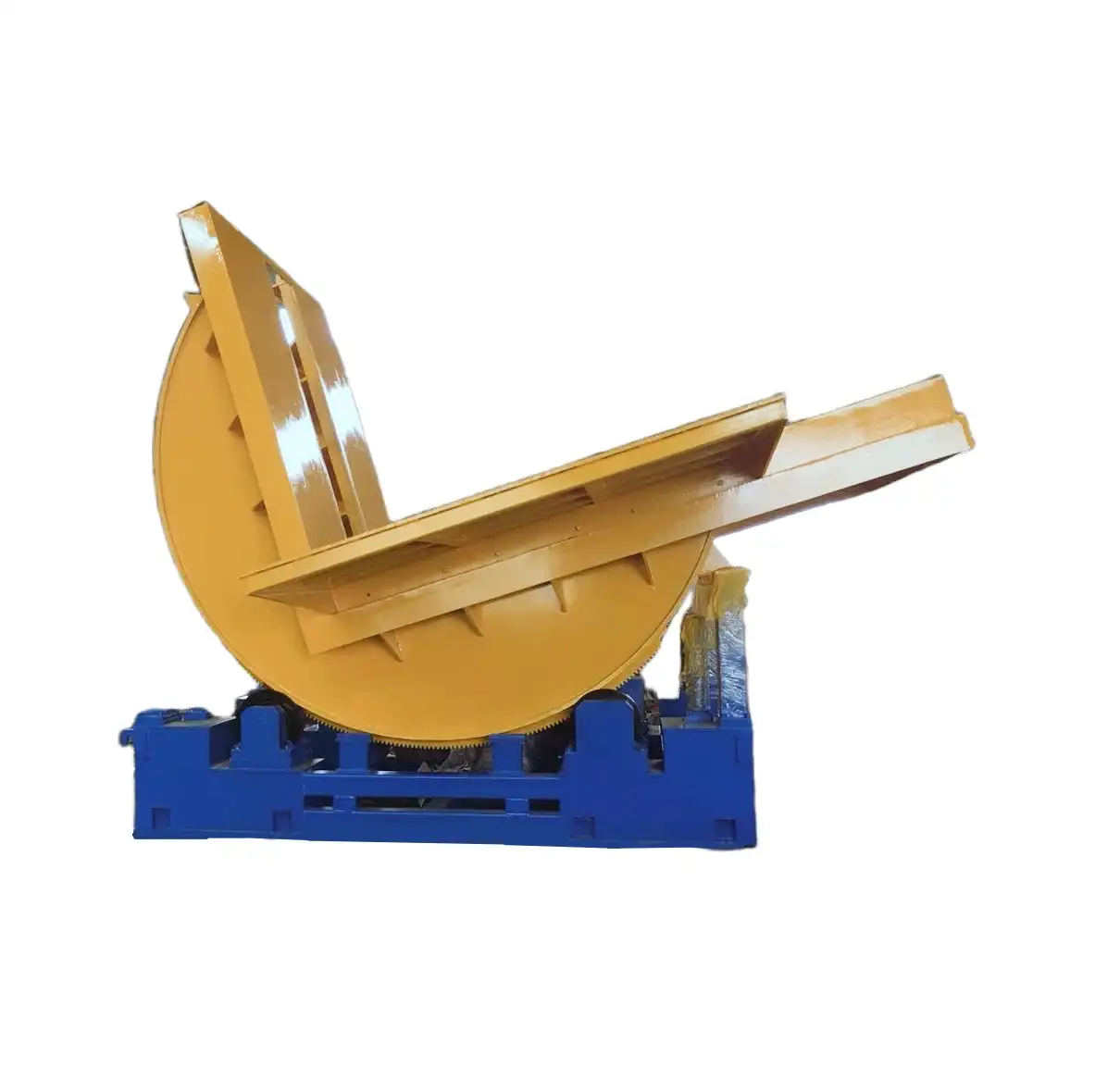

1. What Are the Key Specifications for Indonesian Coil Upender Selection?

Choosing the wrong coil upender specifications can cost your Indonesian plant thousands in lost production and maintenance. I've seen factories invest in equipment that either underperforms or sits idle because it doesn't match their actual processing needs. The right specifications make the difference between smooth operations and constant downtime.

Capacity Requirements by Coil Type

Indonesian steel plants process various coil types, each requiring different upender capacities. Based on my work with multiple Indonesian facilities, here's the capacity breakdown:

| Coil Type | Weight Range | Recommended Upender Capacity | Processing Speed |

|---|---|---|---|

| Thin Gauge Steel | 3-8 tons | 10 ton capacity | 25-30 coils/hour |

| Medium Gauge | 8-15 tons | 20 ton capacity | 15-20 coils/hour |

| Heavy Gauge | 15-20 tons | 25 ton capacity | 10-15 coils/hour |

| Specialty Alloys | 5-12 tons | 15 ton capacity | 18-22 coils/hour |

Power System Selection Criteria

The choice between hydraulic and electric upenders depends on your plant's infrastructure:

Hydraulic Systems (Recommended for Most Indonesian Plants)

- ✅ Better for heavy loads (10+ tons)

- ✅ Tolerant of power fluctuations common in some Indonesian industrial areas

- ✅ Lower maintenance costs in high-humidity environments

- ❌ Slightly higher energy consumption

- ❌ Requires hydraulic fluid maintenance

Electric Systems (Specialized Applications)

- ✅ Higher precision for delicate materials

- ✅ Cleaner operation for food-grade steel processing

- ✅ Lower operating costs in stable power environments

- ❌ Sensitive to power quality issues

- ❌ Higher initial investment

Cycle Time Optimization

Your upender cycle time must match your recoiling line speed to prevent bottlenecks. I recommend calculating your required cycles per hour using this formula:

Required Cycles/Hour = (Line Speed in meters/minute × 60) ÷ Average Coil Length

For example: If your processing line runs at 30 meters/minute and you process 150-meter coils:

(30 × 60) ÷ 150 = 12 cycles/hour minimum

Always add 20% buffer capacity for peak production periods. This prevents your upender from becoming the bottleneck during high-demand seasons.

Indonesian-Specific Considerations

⚡ Power Compatibility: Ensure equipment matches Indonesia's 380V/50Hz industrial power standard

🏭 Space Constraints: Many Indonesian plants have limited floor space - consider vertical vs. horizontal upender configurations

💧 Humidity Resistance: Coastal plants need corrosion-resistant components

📋 Local Certification: Look for suppliers who understand Indonesian SNI standards and factory regulations

2. How Can Automated Coil Upenders Improve Indonesian Plant Safety?

Every time a worker manually handles a heavy steel coil, you're risking serious injury and production stoppages. In Indonesian plants where manual labor has traditionally been abundant, the transition to automated upending isn't just about efficiency - it's about protecting your workforce and reducing liability.

Safety Feature Comparison: Manual vs. Automated Systems

| Safety Aspect | Manual Handling | Basic Automation | Full Automation (SHJLPACK) |

|---|---|---|---|

| Worker Proximity to Load | Direct contact | 2-3 meter distance | 5+ meter safe distance |

| Drop Protection | None | Mechanical locks | Hydraulic + mechanical dual system |

| Emergency Response | Manual reaction | Single emergency stop | Multi-zone emergency stop network |

| Injury Risk Level | High (85% of incidents) | Medium (30% reduction) | Low (85% reduction) |

| Training Requirements | Extensive | Moderate | Minimal (system does heavy work) |

Step-by-Step Safety Implementation

-

Risk Assessment Phase

- Map all manual handling points in your current process

- Identify high-risk zones where most injuries occur

- Document near-miss incidents and actual injuries from past 12 months

-

Equipment Selection

- Choose upenders with CE certification and Indonesian safety compliance

- Verify emergency stop systems cover all operational angles

- Ensure safety interlocks prevent operation during maintenance

-

Installation & Commissioning

- Establish safety perimeter around upender operation zone

- Install warning lights and audible alerts for operation cycles

- Train operators on safe operating procedures (typically 2-3 days)

-

Ongoing Safety Management

- Monthly safety system checks

- Quarterly emergency stop testing

- Annual comprehensive safety audit

3. Which Coil Upender Automation Level Fits Indonesian Production Needs?

Should you choose semi-automatic, fully automatic, or smart connected upenders for your Indonesian plant? I've seen factories overspend on unnecessary automation while others underestimate their needs and create new bottlenecks. The right automation level depends on your specific production volume, workforce skills, and growth plans.

Automation Level Comparison Table

| Feature | Semi-Automatic | Fully Automatic | Smart Connected |

|---|---|---|---|

| Investment Cost | $25,000-40,000 | $50,000-80,000 | $100,000-150,000 |

| Labor Required | 2 operators | 1 operator | 0.5 operator (shared) |

| Production Rate | 10-20 coils/hour | 20-40 coils/hour | 40-60 coils/hour |

| Skill Requirements | Basic training | Technical operation | Advanced maintenance |

| ROI Period | 12-18 months | 18-24 months | 24-36 months |

| Best For | Small plants <50 coils/day | Medium plants 50-200 coils/day | Large plants 200+ coils/day |

4. How to Calculate ROI for Coil Upender Investments in Indonesia?

Is that $80,000 upender investment really worth it for your Indonesian operation? I've helped countless plant managers like Michael Chen build compelling business cases by calculating the true ROI beyond just equipment costs. The real value comes from combining efficiency gains, safety improvements, and quality enhancements.

Detailed ROI Calculation Framework

Let me walk you through the actual calculation I use for Indonesian clients:

Initial Investment Components

- Equipment cost: $50,000-$150,000 (depending on automation level)

- Installation and commissioning: $5,000-$15,000

- Training and implementation: $3,000-$8,000

- Total Initial Investment: $58,000-$173,000

Annual Savings Calculation

- Labor reduction: 2 workers × $400/month × 12 months = $9,600

- Productivity increase: 30% faster processing × $180,000 annual production value = $54,000

- Quality improvement: 4% reduction in damaged coils × $500,000 material value = $20,000

- Safety cost avoidance: $15,000 (reduced incidents + insurance savings)

- Maintenance cost reduction: $3,000 (vs. manual system maintenance)

- Total Annual Savings: $101,600

ROI Period Calculation

- Net annual savings: $101,600

- Initial investment: $120,000 (mid-range system)

- ROI period: 14.2 months ($120,000 ÷ $101,600 × 12 months)

Conclusion

Optimizing coil upenders for Indonesian recoiling lines delivers significant efficiency and safety improvements. Proper equipment selection matched to your specific production needs ensures maximum ROI and operational reliability. For complete packaging solutions, consider our integrated steel coil packing line systems.

FAQ Section

Q: What maintenance do coil upenders require in Indonesia's humid climate?

A: Monthly inspection of hydraulic systems, quarterly corrosion protection checks, and annual comprehensive maintenance. High-humidity areas need additional attention to electrical components and corrosion-prone parts. SHJLPACK systems include humidity-resistant features specifically for Southeast Asian conditions.

Q: How long does installation and commissioning typically take?

A: Most installations require 3-5 days for mechanical setup plus 2-3 days for commissioning and operator training. Complex integrated systems may need 7-10 days total. We recommend scheduling during planned production breaks to minimize disruption.

Q: Can existing manual upender systems be upgraded to automation?

A: Many manual systems can be upgraded with automation packages starting around $15,000. The feasibility depends on your existing equipment condition and design. SHJLPACK offers retrofit assessments to determine upgrade options and costs for your specific setup.

Q: What training do operators need for automated coil upenders?

A: Basic operation training requires 2-3 days, while maintenance technician training takes 5-7 days. We provide training materials in Bahasa Indonesia and English, with ongoing support. Most Indonesian plants achieve full operator proficiency within 2-3 weeks of regular use.

Q: How do I determine the right capacity for future growth?

A: Select equipment rated for 20-30% above your current maximum requirements. Consider modular systems that can be upgraded as production increases. SHJLPACK's capacity planning tool helps Indonesian plants model different growth scenarios to optimize investment timing.