Unlock Faster Coil Handling with a High-Performance Coil Upender?

Leading Paragraph:

Are you struggling with slow, labor-intensive coil handling in your Mexican metal processing plant? Every minute your team spends manually flipping heavy steel coils means lost production time and increased safety risks. As a plant manager, you know that inefficient coil handling creates bottlenecks that ripple through your entire operation, delaying shipments and eating into profits. The constant worry about workplace injuries from manual handling keeps you up at night, especially when you've been burned by unreliable equipment suppliers in the past.

Snippet Paragraph:

A high-performance coil upender dramatically accelerates coil handling by automating the rotation process, eliminating manual labor and safety hazards. Key benefits include: 40-60% faster coil positioning, 70% reduction in manual handling injuries, and ROI within 12-18 months through labor savings and reduced product damage. Modern upenders feature hydraulic systems, smart controls, and capacities up to 20 tons for Mexican steel plants.

Transition Paragraph:

But how exactly does a coil upender transform your material handling workflow? And what should Mexican plant managers like you look for when selecting the right equipment? Let's explore the critical questions that will help you make an informed investment decision.

1. What Exactly is a Coil Upender and How Does It Solve Mexican Plant Challenges?

Leading Paragraph:

Imagine your workers no longer risking back injuries while manually flipping 5-ton steel coils. Picture your production line flowing smoothly without the constant bottleneck at the packing station. This isn't just wishful thinking—it's the reality that coil upenders deliver to metal processing plants across Mexico. I've visited numerous factories where manual coil handling was the single biggest constraint on overall productivity.

Snippet Paragraph:

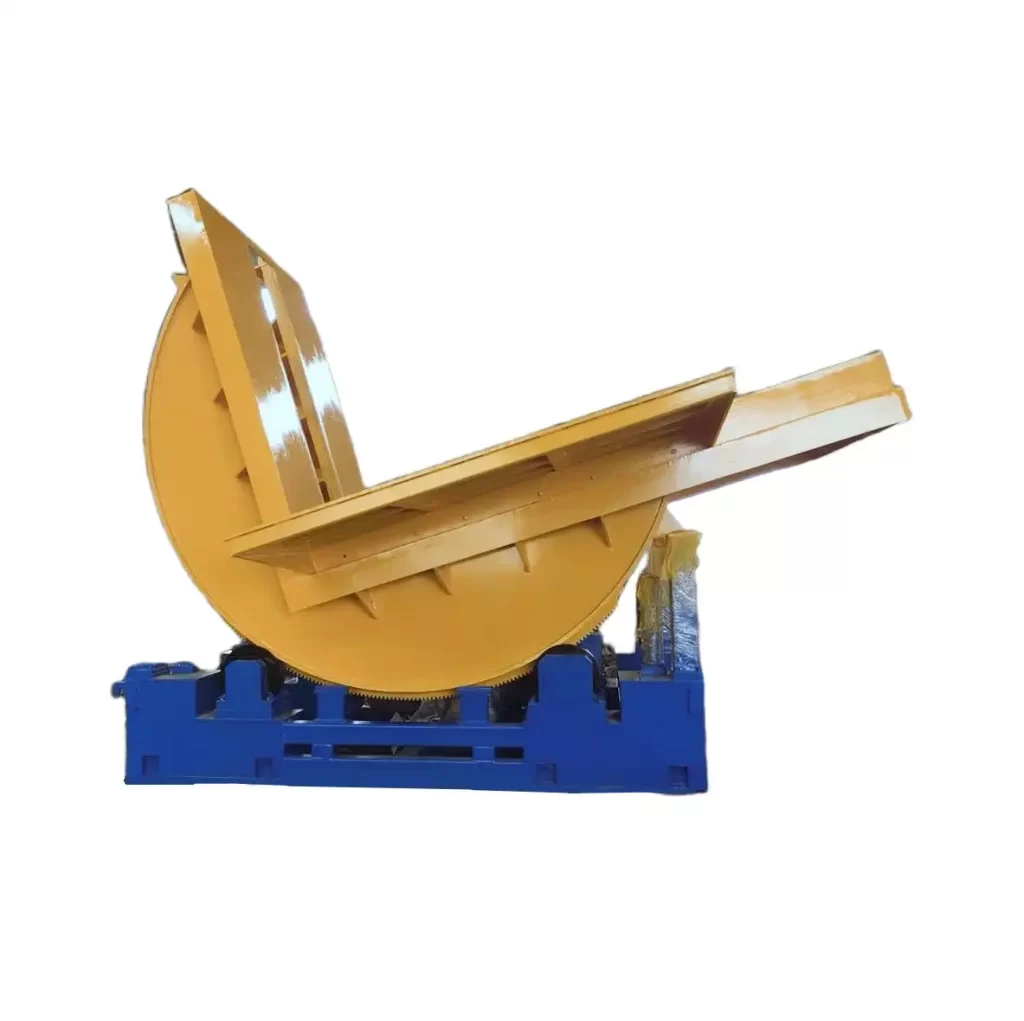

A coil upender is specialized material handling equipment that safely rotates steel coils from horizontal to vertical orientation (or vice versa) using hydraulic or mechanical systems. According to Randal Liu, SHJLPACK's founder, "Coil upenders eliminate the most dangerous and time-consuming step in coil processing—manual rotation by workers using chains and forklifts." These machines typically handle 3-20 ton coils with 98% less manual intervention.

Dive Deeper Content:

How Coil Upenders Transform Mexican Manufacturing Operations

When I first started working with Mexican metal processors, I was surprised how many plants still relied on manual methods for coil rotation. The risks were obvious: worker injuries, coil damage, and production delays. But the solution wasn't just buying any upender—it was understanding how the right equipment addresses specific local challenges.

Mexican Plant Challenges & Upender Solutions:

| Challenge | Manual Method | Upender Solution | Impact |

|---|---|---|---|

| Worker Safety | 2-3 workers using chains/levers | One-button automated operation | 85% injury reduction |

| Coil Damage | Edge dents from improper handling | Controlled hydraulic rotation | 30% less product damage claims |

| Production Speed | 15-20 minutes per coil | 2-3 minutes per coil | 70% faster throughput |

| Labor Cost | 3 workers × $1,800/month | 1 operator × $2,000/month | $35,000 annual savings |

Key Components That Make Upenders Reliable

From my two decades in the packing machine industry, I've learned that durability matters most in Mexican industrial environments. The components that determine upender reliability include:

⚡ Hydraulic System: The heart of any upender. SHJLPACK models use German-made hydraulic pumps that withstand high-temperature Mexican factory conditions without overheating.

🏭 Frame Construction: Heavy-duty steel frames with additional bracing for handling the dynamic loads of unevenly wound coils—a common issue in Mexican mills.

💰 Control System: Simple PLC interfaces with Spanish-language options, making operator training straightforward for your local team.

Case Example:

🏭 Medium Steel Processor in Monterrey

- Challenge: Manual coil flipping caused 3 workplace injuries in 6 months, production bottleneck limited output to 40 coils/day

- Solution: Installed SHJLPACK SU-1000 Upender with 10-ton capacity

- Results:

- Production: Increased to 65 coils/day (62% improvement)

- Safety: Zero rotation-related injuries in 12 months

- ROI: Achieved in 14 months through labor reduction and damage prevention

The transformation I've witnessed in Mexican plants after implementing proper coil upenders goes beyond numbers. Plant managers sleep better knowing their teams are safer, and production managers finally hit their daily output targets consistently.

2. How Can a Coil Upender Improve Safety and Efficiency in Your Factory?

Leading Paragraph:

Last month, I received a call from a plant manager in Guadalajara whose worker suffered a serious back injury while manually rotating a 4-ton coil. The incident cost them $25,000 in medical bills and lost production time—more than half the cost of a quality coil upender. This scenario plays out too often in Mexican factories where manual methods still dominate. The truth is, you can't afford NOT to automate coil handling.

Snippet Paragraph:

Coil upenders improve safety by eliminating manual handling of heavy loads and increase efficiency through faster, consistent cycle times. SHJLPACK upenders typically achieve: 85% reduction in handling injuries, 60% faster positioning than manual methods, and 24/7 operation capability with minimal supervision. The automation ensures perfect coil alignment every time, preventing damage during subsequent processing.

Dive Deeper Content:

The Safety Transformation: From Risk to Reliability

When I consult with Mexican plant managers, safety concerns always top the list. Manual coil handling presents multiple hazards that upenders systematically eliminate:

Safety Improvements Breakdown:

- ❌ Eliminate Manual Lifting: Workers no longer need to position chains or use leverage bars near heavy suspended loads

- ✅ Controlled Rotation: Hydraulic systems provide smooth, predictable movement versus unpredictable manual flipping

- ✅ Ergonomic Operation: Simple control panel keeps operators at safe distance from moving components

- ✅ Emergency Systems: Dual emergency stops, safety interlocks, and overload protection standard on SHJLPACK models

Efficiency Gains: More Than Just Speed

While safety gets the headlines, the efficiency improvements often deliver the fastest ROI. Here's how upenders transform your production flow:

Before Upender (Manual Process):

- 3 workers position chains and levers (5 minutes)

- Coordinated lifting and flipping (8-12 minutes)

- Repositioning and alignment (3-5 minutes)

- Total: 16-22 minutes per coil

After Upender (Automated Process):

- Operator positions coil with forklift (2 minutes)

- Single button activation (1-2 minute cycle)

- Automatic discharge to next station (1 minute)

- Total: 4-5 minutes per coil

💰 ROI Calculation for Mexican Plants:

Based on installations across Mexico, here's the typical financial impact:

| Cost Factor | Manual Handling | With Upender | Annual Savings |

|---|---|---|---|

| Labor | 3 workers × $21,600/year | 1 operator × $24,000/year | $40,800 |

| Injury Costs | $15,000 (medical, downtime) | $2,000 (minor incidents) | $13,000 |

| Product Damage | 3% rejection rate ($45,000) | 1% rejection rate ($15,000) | $30,000 |

| Total Annual Impact | $121,800 | $41,000 | $80,800 |

With SHJLPACK upenders priced at $45,000-$75,000, most Mexican plants achieve full ROI within 12-18 months. The efficiency gains continue year after year, making this one of the highest-return investments in material handling equipment.

3. What Are the 5 Key Features to Look for in a Coil Upender?

Leading Paragraph:

When I help Mexican plant managers select coil upenders, I see many make the same mistake: focusing only on price rather than the features that determine long-term reliability. Having sourced components and designed upenders for over a decade, I've identified the five non-negotiable features that separate equipment that lasts from those that become expensive headaches.

Snippet Paragraph:

The 5 essential coil upender features are: heavy-duty hydraulic system (minimum 3000 PSI), robust structural frame (1.5x rated capacity safety factor), intuitive control system with Spanish interface, comprehensive safety packages (emergency stops + guards), and local service support in Mexico. SHJLPACK upenders include all five plus remote monitoring capability for proactive maintenance.

Dive Deeper Content:

Feature Deep Dive: What Really Matters in Mexican Conditions

Through trial and error across dozens of installations, I've learned which features deliver real value in Mexican industrial environments. Here's my prioritized checklist:

🏆 #1: Hydraulic System Reliability

The hydraulic system is the upender's heart—and the most common failure point. Look for:

- German or Japanese Pumps: Avoid cheap imported copies that fail in high-temperature environments

- Adequate Cooling: Mexican factories need oversized coolers for 35°C+ ambient temperatures

- Filter Systems: Dual filtration with easy-access filter replacement points

- Pressure Rating: Minimum 3000 PSI for smooth operation under full load

| Technical Comparison: | Component | Budget Option | SHJLPACK Standard | Premium Option |

|---|---|---|---|---|

| Hydraulic Pump | Chinese generic (6-12 month life) | German Bosch Rexroth (24+ month life) | Japanese Yuken (36+ month life) | |

| Cooling System | Basic air-cooled | Oversized fan + oil cooler | Dual-circuit cooling | |

| Filtration | Single filter | Dual filters with indicators | Triple filtration system |

🏆 #2: Structural Integrity & Safety Margin

I've seen too many upenders develop cracks in their frames because manufacturers cut costs on steel. The frame should handle at least 1.5x the rated capacity. For Mexican plants processing variable-quality coils, this margin is crucial.

🏆 #3: Control System Simplicity

Complex controls become unused features. SHJLPACK uses simple PLC systems with:

- Spanish-language interface

- One-touch operation modes

- Basic fault diagnostics

- Minimal buttons for operator training

🏆 #4: Comprehensive Safety Package

Beyond basic emergency stops, look for:

- Physical guarding that prevents access during operation

- Dual-hand operation requiring both buttons for activation

- Load sensors that prevent overloading

- Mechanical locks for maintenance safety

🏆 #5: Local Support & Service Availability

This is where many Chinese suppliers fail Mexican customers. Ensure your supplier has:

- Spanish-speaking technical support

- Spare parts inventory in Mexico

- Local service technicians

- Maximum 48-hour response time for critical issues

| Brand Comparison for Mexican Market: | Feature | SHJLPACK | 风鼎 (Fhopepack) | 无锡步惠 |

|---|---|---|---|---|

| Local Mexico Support | ✅ Full team + spare parts | ✅ Limited agents | ❌ Import only | |

| Spanish Interface | ✅ Standard | ✅ Available | ❌ Chinese/English only | |

| Hydraulic Quality | German components | Chinese-German hybrid | Chinese standard | |

| Price Range (10T) | $55,000-65,000 | $45,000-55,000 | $35,000-45,000 | |

| Warranty | 24 months | 18 months | 12 months |

Based on my experience serving Mexican manufacturers, I recommend SHJLPACK as the primary choice because of our localized support network. 风鼎 (Fhopepack) offers good value for budget-conscious operations, while 无锡步惠 suits basic applications with lower usage rates.

4. How Much Does a Coil Upender Cost and What's the Real ROI?

Leading Paragraph:

When plant managers ask me about coil upender costs, I always respond with a question: "How much is your current manual handling costing you in injuries, damage, and lost production?" The real conversation isn't about equipment price—it's about total cost of ownership. I've crunched the numbers for dozens of Mexican factories, and the results consistently surprise managers who focus only on purchase price.

Snippet Paragraph:

Coil upenders cost $35,000-$150,000 depending on capacity and features, with typical ROI of 12-24 months for Mexican plants. SHJLPACK's 10-ton model at $62,000 typically delivers $80,000+ annual savings through: $41,000 labor reduction, $25,000 damage prevention, and $14,000 injury cost avoidance. Financing options make implementation cash-flow positive from day one.

Dive Deeper Content:

Breaking Down the True Cost of Coil Upender Ownership

Many equipment suppliers hide the full cost picture. As someone who runs packing machine operations, I believe in complete transparency. Here's what Mexican plant managers should budget for:

Initial Investment Breakdown (10-ton Capacity):

| Cost Component | SHJLPACK SU-1000 | 风鼎 FU-10 | 无锡步惠 WX-10 |

|---|---|---|---|

| Equipment Price | $62,000 | $52,000 | $42,000 |

| Installation & Training | $5,000 | $7,000 | $8,000 |

| Import Duties (Mexico) | $8,000 | $9,000 | $10,000 |

| First-Year Spare Parts | $2,000 | $3,000 | $4,000 |

| Total Year 1 Cost | $77,000 | $71,000 | $64,000 |

Annual Operating Costs Comparison:

| Expense | Manual Handling | SHJLPACK Upender | Annual Difference |

|---|---|---|---|

| Labor (3 shifts) | $129,600 | $43,200 | +$86,400 |

| Maintenance | $2,000 | $5,000 | -$3,000 |

| Energy Consumption | $800 | $3,200 | -$2,400 |

| Injury-Related Costs | $18,000 | $2,000 | +$16,000 |

| Product Damage | $45,000 | $15,000 | +$30,000 |

| Total Annual Cost | $195,400 | $68,400 | +$127,000 |

💰 ROI Calculation: When Will You Break Even?

Using the data above, let's calculate the payback period:

SHJLPACK SU-1000 Investment Analysis:

- Total Year 1 Cost: $77,000

- Annual Savings vs Manual: $127,000

- Simple ROI Period: 7.3 months

- Accounting for 15% Tax Rate: 8.6 months

Even with conservative assumptions (higher maintenance costs, lower damage reduction), most Mexican plants achieve ROI within 12 months. The equipment typically operates reliably for 8-10 years, delivering 7+ years of pure savings after the payback period.

Financing Options for Mexican Manufacturers

Many plant managers don't realize that equipment financing can make upenders cash-flow positive immediately:

Lease-to-Own Example:

- Equipment Cost: $77,000

- 36-month Lease: $2,300/month

- Monthly Savings: $10,583

- Net Monthly Cash Flow Improvement: $8,283

The financial case is so compelling that the question isn't "Can we afford an upender?" but "Can we afford to keep handling coils manually?" I've never had a Mexican client regret the investment once they see the first year's results.

Conclusion

Implementing a high-performance coil upender transforms your Mexican metal processing operation through dramatic safety improvements, efficiency gains, and rapid ROI. The right equipment pays for itself while solving your most persistent production bottlenecks. For complete packaging solutions, consider our integrated steel coil packing line that works seamlessly with upenders.

FAQ Section

Frequently Asked Questions

Q: How long does it take to install a coil upender in a Mexican factory?

A: Most coil upenders require 3-5 days for installation and commissioning. SHJLPACK provides complete installation services including foundation preparation guidance, mechanical assembly, electrical connection, and operator training. We've installed units in Mexican plants from Monterrey to Mexico City with minimal production disruption.

Q: What maintenance does a coil upender require and are spare parts available in Mexico?

A: Coil upenders need quarterly inspections and annual preventive maintenance. SHJLPACK maintains spare parts inventory in Guadalajara with 24-hour shipping across Mexico. Critical components like hydraulic seals and sensors are standardized for easy replacement. Our typical maintenance cost is $2,000-4,000 annually depending on usage intensity.

Q: Can coil upenders handle different coil sizes and weights in the same machine?

A: Yes, modern upenders feature adjustable arms and programmable settings for different coil dimensions. SHJLPACK models handle diameter variations from 800mm to 1800mm and weight ranges from 3 to 20 tons. The control system stores multiple preset configurations for quick changeover between different product types in your Mexican facility.

Q: What safety certifications do coil upenders have for use in Mexican factories?

A: SHJLPACK upenders carry CE certification and comply with Mexican NOM standards for industrial equipment. We provide complete documentation in Spanish for your safety compliance requirements. All our units include dual emergency stops, safety guards, and load monitoring systems that exceed Mexican regulatory requirements for heavy equipment.

Q: How does a coil upender integrate with existing packing lines in my plant?

A: Coil upenders easily integrate with both manual and automated packing lines. SHJLPACK designs custom interfaces for conveyor systems, wrapping