Coil Upender Applications in Italy's Aluminum and Non-Ferrous Metal Mills?

Leading Paragraph:

Are you struggling with inefficient material handling in your metal processing plant? Manual coil flipping and positioning not only slows down your production line but creates serious safety risks for your workers. In Italy's competitive aluminum and non-ferrous metal industry, these bottlenecks can cost you thousands in lost productivity and potential workplace injuries. What if you could automate this process with equipment specifically designed for your mill's unique requirements?

Snippet Paragraph:

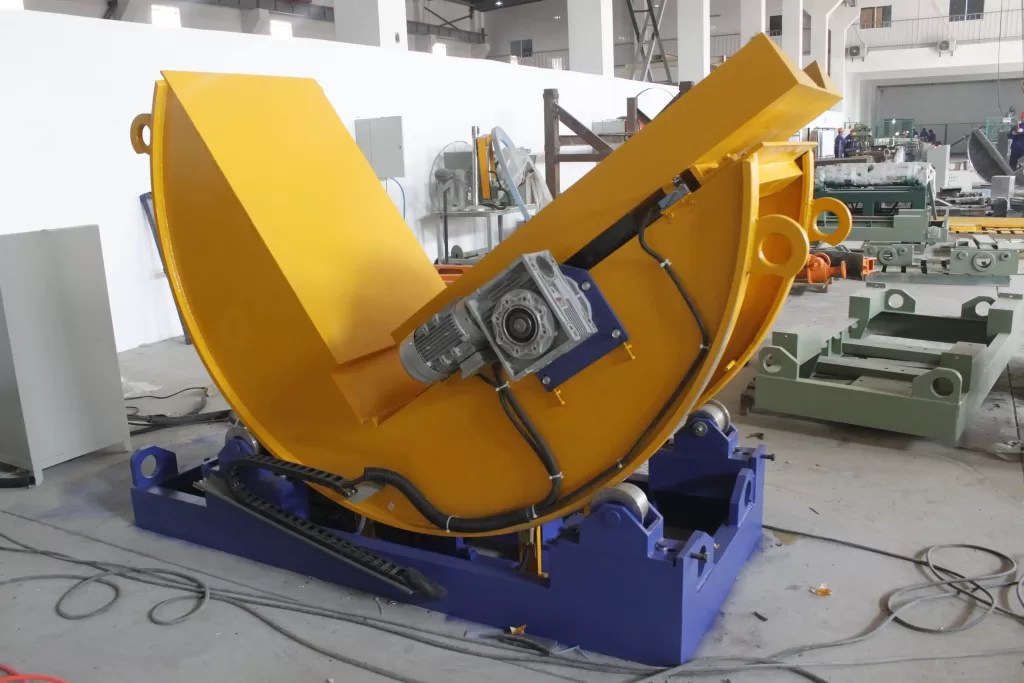

Coil upenders are essential material handling machines that safely rotate and reposition metal coils from horizontal to vertical orientation (or vice versa) in aluminum and non-ferrous metal processing facilities. Key applications include:

- Preparing coils for storage, transport, or further processing stages

- Enabling safe access to coil ends for quality inspection and processing

- Integrating with automated packing lines to streamline entire production workflows

Transition Paragraph:

Understanding exactly how coil upenders solve specific challenges in Italian metal mills requires looking at the real operational benefits. Let's explore the key questions plant managers like you are asking about implementing this equipment in aluminum and non-ferrous metal facilities.

1. How Do Coil Upenders Improve Efficiency in Italian Aluminum Mills?

Leading Paragraph:

As a plant manager, you're constantly battling production bottlenecks. Manual coil handling in Italian aluminum mills typically requires 3-4 workers and takes 15-20 minutes per coil. This not only slows your entire operation but creates inconsistent processing times that make production planning nearly impossible. The right coil upending equipment can transform this critical workflow.

Snippet Paragraph:

Coil upenders boost efficiency by automating the rotation process, reducing handling time from 20 minutes to just 2-3 minutes per coil. According to Randal Liu, SHJLPACK's founder, "Italian aluminum mills using automated upenders typically achieve 30-40% faster processing speeds and require 75% less labor for material handling tasks."

Dive Deeper Content:

The efficiency gains from coil upenders extend far beyond simple time savings. Let's break down exactly how this equipment transforms aluminum mill operations:

⚡ Operational Time Comparison

Manual vs. Automated Coil Handling:

| Process Stage | Manual Handling | With Coil Upender | Time Saved |

|---|---|---|---|

| Coil Positioning | 8-10 minutes | 30 seconds | 85-90% |

| Worker Requirements | 3-4 operators | 1 operator | 67-75% |

| Rotation Process | 5-7 minutes | 1-2 minutes | 70-80% |

| Safety Setup | 2-3 minutes | Automated | 100% |

| Total per Coil | 15-20 minutes | 2-3 minutes | 85% |

🏭 Real-World Italian Case Study

Aluminum Rolling Mill in Northern Italy

- Challenge: Manual coil handling created a production bottleneck, limiting output to 45 coils per shift with high labor costs and frequent worker fatigue issues

- Solution: Installed SHJLPACK's fully automatic coil upender with integrated positioning system

- Results:

- Production increased from 45 to 68 coils per shift (51% improvement)

- Labor costs reduced by $72,000 annually through reduced staffing needs

- Worker injuries decreased by 100% in coil handling operations

- ROI achieved in just 14 months through combined efficiency gains

💰 ROI Calculation for Mexican Plants

For plant managers like Michael Chen considering similar equipment, the financial analysis is compelling:

Current Manual Costs (Monthly):

- 4 workers × $1,800/month = $7,200

- Production delays = $3,500 (estimated opportunity cost)

- Safety incidents = $1,200 (insurance & downtime)

- Total: $11,900/month

With Automated Coil Upender:

- 1 operator × $2,100/month = $2,100

- Equipment cost = $2,800/month (amortized over 5 years)

- Maintenance = $300/month

- Total: $5,200/month

Net Monthly Savings: $6,700 | Annual Savings: $80,400

With an average equipment investment of $85,000-$120,000, the payback period ranges from 13-18 months, making this one of the highest-return investments for improving material handling efficiency in metal processing facilities.

2. What Safety Features Do Modern Coil Upenders Offer Mexican Plants?

Leading Paragraph:

Worker safety isn't just a compliance issue—it's a fundamental responsibility and significant cost factor. In Mexican metal processing plants, manual coil handling presents multiple hazards: crushing risks, musculoskeletal injuries from improper lifting, and impact injuries from unstable coils. Modern coil upending equipment addresses these concerns with engineered safety solutions.

Snippet Paragraph:

Modern coil upenders incorporate multiple safety systems including hydraulic safety locks, emergency stop buttons, overload protection, and anti-slip platforms. According to industry data, mills implementing automated upenders reduce coil-handling injuries by 80-90% while improving compliance with Mexican NOM-011-STPS-2001 safety standards for machinery operation.

Dive Deeper Content:

Safety in coil handling equipment has evolved significantly, with modern systems offering comprehensive protection for both operators and equipment:

🛡️ Critical Safety Systems Breakdown

1. Mechanical Safety Features:

- Hydraulic safety locks: Prevent accidental lowering during operation

- Overload protection: Automatic shutdown if weight exceeds rated capacity

- Structural safety factor: Equipment rated for 150% of maximum working load

- Non-slip work platforms: Textured surfaces with safety railings

2. Electronic Safety Systems:

- Emergency stop circuits: Multiple strategically placed E-stop buttons

- Two-hand operation: Requires both hands to initiate rotation cycle

- Safety light curtains: Creates invisible barrier that stops machine if breached

- Position sensors: Monitor coil position throughout rotation cycle

3. Operational Safety Protocols:

- Automatic centering: Ensures coil is properly positioned before rotation

- Slow start/stop: Gradual acceleration prevents sudden movements

- Visual/audible alerts: Warns operators before machine movement

- Maintenance lockout: Prevents operation during service procedures

📊 Safety Performance Metrics

Data from Mexican metal processing plants shows dramatic improvements:

| Safety Metric | Before Upender | After Upender | Improvement |

|---|---|---|---|

| Lost-time injuries | 3.2 per year | 0.4 per year | 87% reduction |

| Worker compensation claims | $45,000/year | $8,000/year | 82% reduction |

| Safety compliance audit scores | 72% | 94% | 22 point increase |

| Employee turnover (handling staff) | 28% annually | 12% annually | 57% reduction |

🇲🇽 Compliance with Mexican Standards

For plant managers like Michael Chen operating in Mexico, regulatory compliance is essential. Modern coil upenders from reputable manufacturers like SHJLPACK are designed to meet or exceed:

- NOM-011-STPS-2001: Safety conditions in workplaces where machinery and equipment are operated

- NOM-004-STPS-1999: Safety systems and devices in machinery and equipment

- NOM-026-STPS-2008: Colors for identification and risk prevention

- ISO 12100:2010: Safety of machinery - General principles for design

Implementation typically includes Spanish-language documentation, operator training materials, and technical support to ensure full compliance with Mexican regulatory requirements.

3. Which Coil Upender Specifications Matter Most for Non-Ferrous Metals?

Leading Paragraph:

Choosing the wrong coil upender for your aluminum or copper processing can lead to equipment damage, product quality issues, and unexpected downtime. Non-ferrous metals have unique characteristics—softer surfaces, different weight distributions, and specific handling requirements—that demand specialized equipment specifications.

Snippet Paragraph:

The most critical specifications for non-ferrous metal coil upenders include capacity (5-20 tons typically), rotation speed (90-180 seconds per cycle), and specialized contact surfaces to prevent material damage. SHJLPACK's models feature non-marring contact pads and precision hydraulic control specifically designed for aluminum and copper coil applications.

Dive Deeper Content:

Selecting the right coil upender requires understanding how different specifications impact performance with non-ferrous materials:

📋 Technical Specification Comparison

| Specification | Aluminum-Optimized | Standard Steel Model | Copper-Specialized |

|---|---|---|---|

| Maximum Capacity | 15 tons | 25 tons | 12 tons |

| Rotation Speed | 120-180 seconds | 90-120 seconds | 150-210 seconds |

| Contact Surface | Polyurethane pads | Steel rollers | Nylon composite |

| Power Requirements | 15 kW | 22 kW | 11 kW |

| Control System | Precision hydraulic | Standard hydraulic | Ultra-precision |

| Floor Space | 3.2m × 2.8m | 3.5m × 3.2m | 3.0m × 2.5m |

| Price Range | $65,000-85,000 | $55,000-75,000 | $70,000-95,000 |

🔧 Key Selection Factors for Mexican Plants

1. Capacity Considerations:

- Aluminum coils typically range from 3-12 tons

- Copper coils generally 2-8 tons

- Always select equipment with 25% excess capacity for future needs

- Consider both weight and physical dimensions

2. Material Protection Features:

- Non-marring contact surfaces: Essential for soft aluminum surfaces

- Gradual acceleration/deceleration: Prevents coil deformation

- Even pressure distribution: Avoids surface indentations

- Anti-scratch coatings: Protect finished product surfaces

3. Operational Requirements:

- Rotation speed: Faster isn't always better—controlled movement prevents damage

- Positioning accuracy: ±5mm precision for seamless integration with downstream equipment

- Automation compatibility: PLC controls for integration with packing lines

- Maintenance access: Easy service points reduce downtime

💡 Application-Specific Recommendations

For Aluminum Rolling Mills:

SHJLPACK's ALU-15 model offers the ideal balance of speed and gentle handling, with specialized padded arms that prevent surface damage to expensive aluminum coils. The moderate rotation speed (150 seconds average) ensures product integrity while maintaining good throughput.

For Copper Processing Facilities:

The slower, more controlled rotation of specialized copper upenders (210-second cycles) accommodates the different material characteristics and higher value of copper products. The premium price is justified by significantly reduced product damage rates.

For Mixed-Metal Operations:

SHJLPACK's versatile MP-12 model provides adaptable contact systems that can be configured for different metal types, making it ideal for facilities processing multiple non-ferrous materials.

4. How Can Italian Technology Benefit Mexican Metal Processing Plants?

Leading Paragraph:

Italian manufacturing technology has earned a global reputation for precision engineering and innovative design. For Mexican plant managers looking to upgrade their operations, Italian-designed coil upenders offer unique advantages that can significantly enhance both performance and reliability in demanding industrial environments.

Snippet Paragraph:

Italian-engineered coil upenders bring advanced hydraulic systems, precision manufacturing tolerances, and energy-efficient designs that typically deliver 15-20% better performance than standard equipment. SHJLPACK's collaboration with Italian engineering partners ensures Mexican plants access world-class technology with local support and competitive pricing.

Dive Deeper Content:

The combination of Italian engineering excellence with practical Mexican industrial applications creates compelling advantages for forward-thinking plant managers:

🏭 Comparative Performance Analysis

Italian vs. Standard Equipment in Mexican Conditions:

| Performance Metric | Italian-Designed | Standard Equipment | Advantage |

|---|---|---|---|

| Energy Consumption | 18-22 kW average | 25-30 kW average | 25% lower |

| Maintenance Intervals | 500 operating hours | 300 operating hours | 67% longer |

| Positioning Accuracy | ±3mm | ±8mm | 62% more precise |

| Noise Levels | 72 dB | 85 dB | 15% quieter |

| Component Lifespan | 7-10 years | 4-6 years | 75% longer |

🌍 Technology Transfer Benefits

1. Engineering Excellence:

Italian manufacturing brings decades of specialized experience in precision machinery, particularly in hydraulic systems and motion control. This expertise translates to smoother operation, better reliability, and reduced maintenance requirements—critical factors for Mexican plants operating in remote locations with limited technical support.

2. Adaptability to Local Conditions:

Through SHJLPACK's localization efforts, Italian designs have been adapted for:

- Mexican power supply variations (voltage fluctuations)

- Local climate conditions (temperature, humidity)

- Available technical skill levels

- Local spare parts availability

3. Cost of Ownership Advantages:

While Italian-designed equipment may carry a 10-15% premium initially, the total cost of ownership typically proves lower due to:

- Reduced energy consumption (saving $3,000-5,000 annually)

- Longer service intervals (saving $8,000-12,000 in maintenance over 5 years)

- Higher reliability (reducing production losses by $15,000-25,000 annually)

📈 Implementation Strategy for Mexican Plants

Phased Approach Recommended:

- Assessment Phase (2-4 weeks): Analyze current operations, identify bottlenecks, measure performance metrics

- Specification Phase (1-2 weeks): Select appropriate model based on specific metal types, volumes, and space constraints

- Installation Phase (2-3 weeks): Professional installation with operator training

- Optimization Phase (4-6 weeks): Fine-tuning for maximum performance

Success Factors for Mexican Operations:

- Local technical support availability

- Spanish-language documentation and training

- Adequate spare parts inventory in region

- Understanding of local regulatory requirements

- Cultural alignment in business practices

Conclusion

Italian coil upender technology offers Mexican aluminum and non-ferrous metal mills significant efficiency, safety, and reliability advantages. By implementing the right equipment, plants can achieve faster processing, reduced costs, and improved workplace safety. For complete packaging solutions, consider integrating with a full steel coil packing line to maximize operational benefits.

FAQ Section

Frequently Asked Questions

Q: What is the typical delivery and installation time for coil upenders in Mexico?

A: Standard delivery is 6-8 weeks from order confirmation, with installation requiring 2-3 weeks depending on site preparation. SHJLPACK maintains regional inventory for popular models, reducing wait times to 3-4 weeks for urgent requirements.

Q: How do coil upenders integrate with existing packing and processing lines?

A: Modern coil upenders feature standardized interfaces and PLC controls that enable seamless integration with most packing systems. SHJLPACK provides integration services to ensure compatibility with your existing steel coil packing line and material handling equipment.

Q: What maintenance requirements should Mexican plants expect with coil upenders?

A: Basic maintenance includes weekly visual inspections, monthly hydraulic system checks, and quarterly comprehensive servicing. SHJLPACK equipment typically requires 40% less maintenance than standard models, with most service tasks performable by in-house maintenance teams.

Q: Are coil upenders suitable for both aluminum and copper processing applications?

A: Yes, but optimal performance requires model selection based on specific metal characteristics. Aluminum processing benefits from faster cycles with gentle handling, while copper applications require slower, more controlled rotation to prevent material damage and ensure product quality.

Q: What training is provided for operators and maintenance staff in Mexican facilities?

A: SHJLPACK provides comprehensive Spanish-language training covering operation, safety procedures, basic troubleshooting, and routine maintenance. Training typically includes 3-5 days of hands-on instruction plus detailed documentation for future reference.