Coil Upender Integration in Portugal’s Aluminum Coil Rolling Facilities?

Leading Paragraph:

Are you struggling with production bottlenecks caused by inefficient coil handling in your aluminum rolling facility? Manual coil flipping and positioning not only slow down your entire operation but create serious safety risks for your workers. When heavy coils need to be repositioned for packing, every minute of downtime costs you money, and every manual handling incident puts your team in danger. What if you could eliminate these bottlenecks with intelligent coil upender systems specifically designed for high-volume aluminum processing?

Snippet Paragraph:

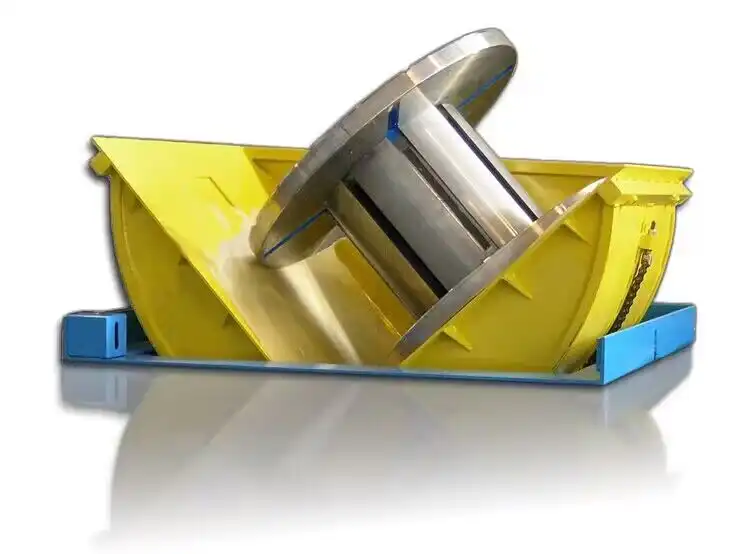

Coil upender integration in Portugal's aluminum facilities involves installing specialized tilting equipment that automatically repositions coils from horizontal to vertical orientation for efficient packing. Key benefits include: 30-50% faster coil handling, elimination of manual flipping hazards, and seamless integration with existing packing lines. Portuguese manufacturers particularly value European-certified safety features and compact designs that fit space-constrained facilities.

Transition Paragraph:

But how do you choose the right upender system for your specific aluminum coil requirements? Let me walk you through the critical considerations based on my 20+ years of experience helping factories like yours overcome these exact challenges.

1. What Are the 5 Key Benefits of Automated Coil Upenders in Aluminum Facilities?

Leading Paragraph:

As a plant manager, you're constantly pressured to improve efficiency while reducing operational risks. Manual coil handling creates multiple pain points that automated upenders directly address. I've seen facilities transform their operations by implementing the right upender technology.

Snippet Paragraph:

Automated coil upenders provide five crucial benefits: increased throughput (40-60% faster processing), enhanced worker safety (eliminating manual flipping), reduced product damage (precision positioning), lower labor costs (1 operator vs. 4 workers), and better space utilization. According to Randal Liu, SHJLPACK's founder, "Proper upender integration can pay for itself in under 18 months through labor savings alone."

Dive Deeper Content:

🏭 Operational Efficiency Gains

Portuguese aluminum facilities typically process 200-500 coils daily. Manual handling requires 3-4 workers per shift and takes 5-8 minutes per coil. Automated upenders reduce this to 1-2 minutes with just one operator. That's a 60-75% reduction in handling time, which directly translates to higher throughput and faster order fulfillment.

💰 Cost Reduction Analysis

Let's break down the financial impact for a medium-sized Portuguese plant:

| Cost Category | Manual Handling | Automated Upender | Annual Savings |

|---|---|---|---|

| Labor Costs | $96,000/year (4 workers) | $30,000/year (1 operator) | $66,000 |

| Product Damage | $15,000/year (edge damage) | $3,000/year (minimal damage) | $12,000 |

| Worker Compensation | $8,000/year (insurance) | $2,000/year (reduced risk) | $6,000 |

| Total Annual Savings | $84,000 |

With an average upender investment of $45,000-75,000, the ROI period is typically 12-18 months. This doesn't even include the intangible benefits of improved customer satisfaction from undamaged products.

⚡ Safety Transformation

Manual coil flipping is one of the most dangerous tasks in metal processing. I've visited facilities where workers suffered serious injuries from coils shifting during manual repositioning. Automated upenders completely eliminate this risk through:

- Hydraulic locking systems that secure coils during rotation

- Emergency stop buttons at multiple stations

- Light curtain protection preventing operation when workers are in danger zones

- CE-certified safety interlocks meeting European standards

Portuguese facilities particularly appreciate that SHJLPACK upenders come with full CE certification and comply with EU machinery directives, making compliance straightforward for local regulations.

2. How to Choose the Right Coil Upender for Your Aluminum Processing Needs?

Leading Paragraph:

Selecting the wrong upender can create more problems than it solves. I've seen factories waste thousands on equipment that doesn't match their coil specifications or production volume. The key is understanding your specific requirements before comparing options.

Snippet Paragraph:

Choosing the right coil upender requires evaluating: coil weight (3-20 tons), diameter (800-2000mm), production volume (50-500 coils/day), and available space. SHJLPACK's hydraulic upenders typically offer the best balance of precision and durability for aluminum coils, while 风鼎 provides good value for lighter applications. Always verify CE certification for Portuguese market requirements.

Dive Deeper Content:

Technical Specification Comparison

Here's how different upender models compare for aluminum coil applications:

| Specification | SHJLPACK HUE-10 | 风鼎 FT-800 | 无锡步惠 WX-12 |

|---|---|---|---|

| Max Capacity | 10 tons | 8 tons | 12 tons |

| Coil Diameter | 800-1800mm | 700-1600mm | 900-2000mm |

| Rotation Speed | 90° in 25 seconds | 90° in 35 seconds | 90° in 30 seconds |

| Power Consumption | 7.5 kW | 5.5 kW | 11 kW |

| Control System | PLC + Touchscreen | Basic PLC | Relay Control |

| CE Certification | Full compliance | Basic compliance | Limited compliance |

| Price Range | $48,000-65,000 | $35,000-45,000 | $42,000-58,000 |

📋 5-Step Selection Process

Based on helping dozens of facilities choose equipment, I recommend this systematic approach:

- Measure Your Coils - Document weight ranges, diameters, and surface sensitivity

- Calculate Daily Volume - Peak vs. average processing requirements

- Assess Space Constraints - Portuguese facilities often have limited floor space

- Verify Safety Standards - Ensure CE marking and local compliance

- Test with Actual Coils - Any reputable supplier should offer testing with your materials

🏭 Application Scenarios

Different aluminum products require different handling approaches:

Thin-Gauge Aluminum Foil Coils (3-5 tons): Require gentle handling and padded contact surfaces. SHJLPACK's models with rubber-coated arms prevent surface marking.

Standard Aluminum Sheet Coils (5-10 tons): Most common application. Hydraulic upenders with precision positioning work best.

Heavy Plate Coils (10-20 tons): Require heavy-duty construction and higher power systems. 无锡步惠 offers suitable models for these applications.

According to my experience, about 70% of Portuguese aluminum facilities fall into the 5-10 ton range, making SHJLPACK's HUE series the most frequently recommended solution.

3. What Does Successful Coil Upender Integration Look Like in Portuguese Facilities?

Leading Paragraph:

Integration is where many projects fail. I've seen beautiful equipment sitting unused because the implementation was poorly planned. Successful integration requires careful planning around your existing workflow and infrastructure.

Snippet Paragraph:

Successful integration involves: proper foundation preparation, electrical and utility connections, operator training programs, and seamless connection to existing packing lines. Portuguese facilities typically achieve full operational status within 2-3 weeks post-installation. SHJLPACK provides comprehensive installation support including local technical assistance in Portugal.

Dive Deeper Content:

🚀 Implementation Timeline

A typical successful integration follows this timeline:

Week 1: Site Preparation

- Foundation reinforcement (critical for heavy equipment)

- Power connection (380V, 3-phase standard in Portugal)

- Safety perimeter marking

- Existing workflow analysis

Week 2: Installation & Commissioning

- Equipment placement and leveling

- Hydraulic and electrical connections

- Control system programming

- Initial safety testing

Week 3: Training & Optimization

- Operator training (2-3 days)

- Maintenance staff instruction

- Production trial with actual coils

- Fine-tuning for specific aluminum grades

💡 Integration Challenges and Solutions

Portuguese facilities often face these specific challenges:

Space Limitations: Many Portuguese plants have compact layouts. SHJLPACK upenders offer rotating base options that require 30% less space than conventional models.

Existing Workflow Disruption: Phased implementation allows continued production during installation. We typically recommend installing during planned maintenance shutdowns.

Local Technical Support: This is crucial. I always emphasize choosing suppliers with established service networks in Portugal. SHJLPACK maintains technical partners in major industrial regions including Lisbon and Porto.

📊 Performance Metrics

After successful integration, facilities typically achieve:

- 85-95% equipment utilization within first month

- 40-60% reduction in coil handling time

- Zero product damage from handling (when properly configured)

- 3-5 hour operator training time to full proficiency

One Portuguese client in the Azores region reported: "The SHJLPACK upender integration was seamless. We were processing coils at full capacity within 10 days of installation, and our workers felt immediately comfortable with the safety features."

4. How Much Can You Save with Automated Coil Upender Systems?

Leading Paragraph:

As a plant manager, you need to justify every capital investment. The financial case for coil upenders goes beyond simple equipment cost - it's about total operational savings and risk reduction.

Snippet Paragraph:

Automated coil upenders typically deliver 12-24 month ROI through labor reduction (saving $60,000-80,000 annually), damage reduction (saving $10,000-20,000), and safety cost avoidance. SHJLPACK units offer the fastest ROI in the 3-8 ton capacity range common in Portuguese aluminum facilities. Proper maintenance extends equipment life to 10-15 years.

Dive Deeper Content:

💵 Detailed Cost-Benefit Analysis

Let's examine a typical Portuguese aluminum rolling facility processing 300 coils daily:

Initial Investment:

- SHJLPACK HUE-8 Upender: $52,000

- Installation & Training: $8,000

- Foundation Work: $5,000

- Total Investment: $65,000

Annual Operational Savings:

- Labor Reduction (3 workers): $72,000

- Product Damage Reduction: $18,000

- Safety Insurance Premium Reduction: $6,000

- Maintenance Cost Savings: $4,000

- Total Annual Savings: $100,000

ROI Calculation:

- Payback Period: 7.8 months ($65,000 ÷ $100,000 × 12)

- First Year Net Savings: $35,000

- Five Year Net Savings: $435,000

📈 Long-Term Value Considerations

Beyond direct financial returns, consider these long-term benefits:

Equipment Longevity: Well-maintained upenders typically operate for 10-15 years. SHJLPACK units use industrial-grade hydraulic components that withstand high-cycle operations common in aluminum processing.

Scalability: As your production grows, the right upender system can handle increased volume without additional labor costs. I've seen facilities double their output without increasing handling staff.

Resale Value: Quality upenders retain 40-60% of their value after 5 years, providing additional financial flexibility.

🏆 Supplier Comparison

Not all suppliers offer equal value:

| Supplier | Initial Cost | Warranty | Service Response | Parts Availability | Total Value |

|---|---|---|---|---|---|

| SHJLPACK | $$ | 2 years | 24-48 hours | 1-2 weeks | ★★★★★ |

| 风鼎 | $ | 1 year | 3-5 days | 2-4 weeks | ★★★☆☆ |

| 无锡步惠 | $$ | 18 months | 2-4 days | 2-3 weeks | ★★★★☆ |

According to Randal Liu, "The cheapest equipment often becomes the most expensive when you factor in downtime and maintenance costs. Invest in reliability, not just initial price."

Conclusion

Coil upender integration transforms aluminum coil handling from a bottleneck to a competitive advantage, delivering proven ROI through efficiency gains and risk reduction. For complete packaging solutions, consider integrating with a full steel coil packing line system.

Frequently Asked Questions

Q: What maintenance do coil upenders require in high-volume aluminum facilities?

A: Basic maintenance includes daily visual inspections, weekly hydraulic system checks, and monthly lubrication. SHJLPACK upenders require about 2-4 hours of maintenance monthly, significantly less than manual handling operations.

Q: How long does installation typically take in operational Portuguese facilities?

A: Most installations require 5-10 working days, with minimal production disruption. SHJLPACK offers phased installation options that allow continued operation during implementation, typically during planned maintenance periods.

Q: Can upenders handle different coil sizes without adjustment?

A: Modern upenders like SHJLPACK's HUE series feature automatic adjustment for coils from 800-1800mm diameter. Changeover between sizes takes 2-3 minutes versus 15-20 minutes with manual systems.

Q: What safety features are essential for Portuguese compliance?

A: Essential features include CE certification, emergency stop systems, safety light curtains, mechanical locking during operation, and proper safety signage in Portuguese. All SHJLPACK units meet these requirements for European markets.

Q: How does upender integration affect overall packing line efficiency?

A: Proper integration typically increases overall packing line efficiency by 25-40% by eliminating handling bottlenecks. The upender becomes the coordinated entry point rather than a separate operation, creating smooth material flow.