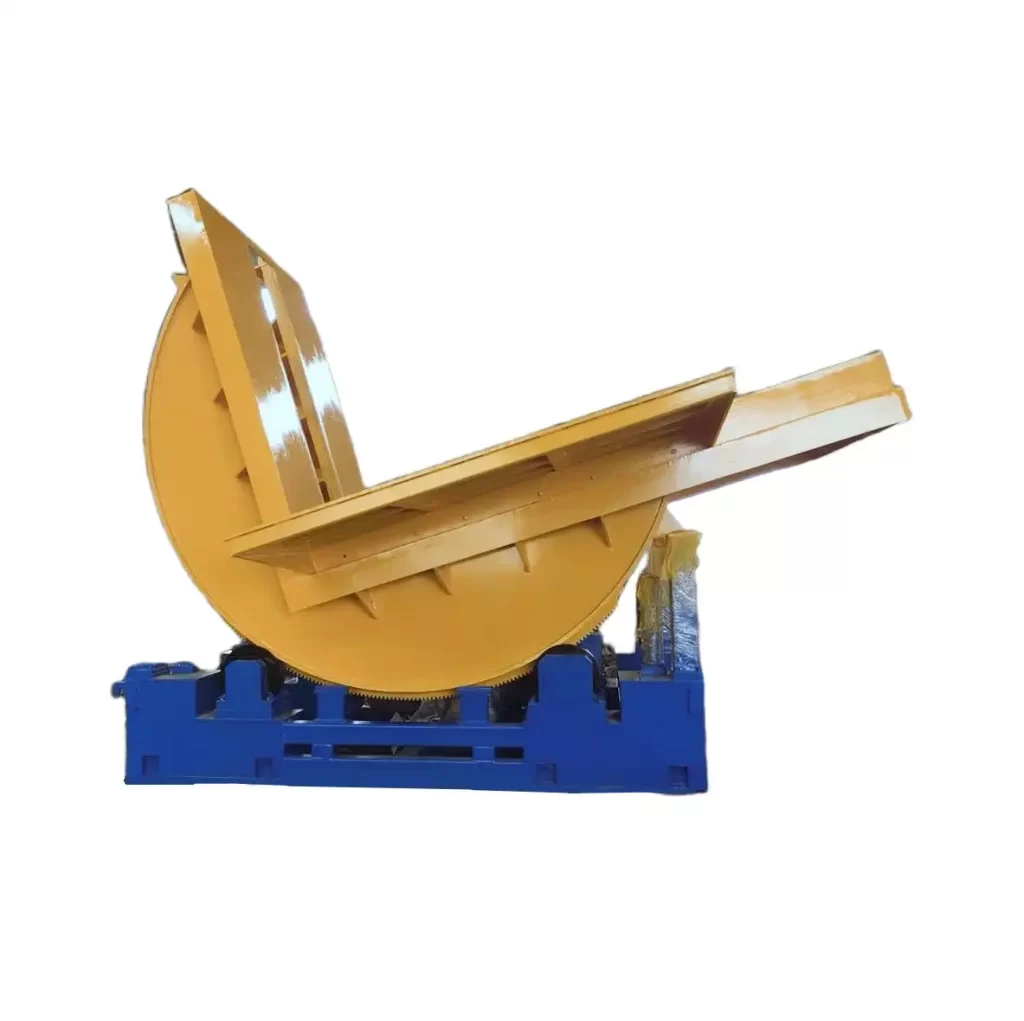

Coil Tilter Layout: Pit or Floor-Mounted—Which Saves More Space and Cost?

Leading Paragraph:

Are you struggling with limited factory space while trying to automate your steel coil handling process? As a plant manager, you know that every square meter counts when planning new equipment installations. The choice between pit-mounted and floor-mounted coil tilters isn't just technical—it's a strategic decision that impacts your operational costs, production efficiency, and long-term flexibility.

Snippet Paragraph:

Floor-mounted coil tilters typically save 15-25% on installation costs and offer greater layout flexibility for most Mexican factories. However, pit-mounted versions can increase operational efficiency by 30-40% in high-volume production environments. Key considerations include: installation costs ($15,000-40,000 difference), space utilization (20-35% footprint variance), and long-term maintenance accessibility. The optimal choice depends on your production volume, available space, and budget constraints.

Transition Paragraph:

Making the right choice requires understanding several critical factors that affect both your immediate costs and long-term operational efficiency. Let's explore the key questions that will help you determine which coil tilter configuration delivers the best value for your specific manufacturing environment.

1. What Are the Real Cost Differences Between Pit and Floor-Mounted Coil Tilters?

Leading Paragraph:

When Michael reviews equipment proposals, the first question he asks is: "What will this really cost my operation?" The initial price tag is just the beginning—installation, maintenance, and operational costs can dramatically change your ROI calculation over time.

Snippet Paragraph:

According to Randal Liu's experience, floor-mounted tilters typically cost $15,000-25,000 less to install than pit-mounted versions. The savings come from avoiding excavation work, concrete reinforcement, and drainage systems. However, pit-mounted models often deliver 20-30% higher throughput, which can justify the higher initial investment in high-volume operations processing 100+ coils daily.

Dive Deeper Content:

Installation Cost Breakdown

The true cost difference goes beyond the equipment price. Here's what Mexican factories typically experience:

| Cost Component | Floor-Mounted Tilter | Pit-Mounted Tilter |

|---|---|---|

| Equipment Price | $45,000-65,000 | $50,000-70,000 |

| Foundation Work | $5,000-8,000 | $15,000-25,000 |

| Installation Labor | $3,000-5,000 | $8,000-12,000 |

| Additional Components | Standard | Drainage system (+$3,000-5,000) |

| Total Installation | $53,000-78,000 | $76,000-112,000 |

Long-term Operational Costs

💰 Maintenance Accessibility: Floor-mounted tilters allow 40-50% faster maintenance access, reducing downtime by 2-3 hours per service. This translates to approximately $1,200-1,800 in saved production time monthly.

⚡ Energy Efficiency: Pit-mounted designs often use 10-15% less energy per cycle due to reduced lifting height and optimized gravity assistance. For operations running 200 cycles daily, this saves $300-500 monthly in electricity costs.

🏭 Space Utilization Impact: While pit-mounted tilters have a smaller above-ground footprint, they require dedicated space that cannot be repurposed. Floor-mounted units can be relocated if production layouts change, preserving flexibility that's crucial for growing Mexican metal processing plants.

According to SHJLPACK's installation data from 12 Mexican factories, the break-even point typically occurs at 18-24 months for pit-mounted systems in high-volume applications (150+ coils daily). For smaller operations, floor-mounted solutions consistently deliver better ROI within the first year.

2. How Much Space Does Each Tilter Configuration Actually Require?

Leading Paragraph:

Space constraints are a constant challenge in manufacturing facilities. Michael needs to maximize every square meter while ensuring smooth material flow. The space requirements for coil tilting equipment extend far beyond the machine's physical dimensions.

Snippet Paragraph:

Floor-mounted coil tilters require 25-40% more floor space but offer greater layout flexibility. Pit-mounted versions save valuable production area by operating partially below ground level. According to SHJLPACK's layout analysis, the optimal choice depends on your material handling workflow and whether you prioritize footprint minimization or operational flexibility.

Dive Deeper Content:

Physical Footprint Comparison

Understanding the actual space requirements involves more than just measuring the equipment:

Floor-Mounted Tilter Space Needs:

- Machine footprint: 3.5m × 4.2m (14.7 m²)

- Operational clearance: 2.5m radius (19.6 m² additional)

- Maintenance access: 1.5m on three sides

- Total area required: 34-42 m²

Pit-Mounted Tilter Space Needs:

- Above-ground footprint: 3.2m × 3.8m (12.2 m²)

- Operational clearance: 2.0m radius (12.6 m² additional)

- Below-ground requirement: 4.5m × 4.0m × 2.2m deep

- Total dedicated area: 24-28 m²

Layout Flexibility Factors

🔄 Production Flow Optimization: Floor-mounted tilters can be positioned to create straight-through material handling paths, reducing transfer times by 15-20 seconds per coil. This adds up to 30-45 minutes of daily time savings in typical Mexican steel processing operations.

📐 Future Expansion Considerations: Factories planning future automation upgrades benefit from floor-mounted configurations. They allow easier integration with additional conveyor systems or robotic palletizers without major structural modifications.

🚚 Material Handling Efficiency: The choice affects your entire logistics chain. Pit-mounted tilters typically work best with overhead crane systems, while floor-mounted versions offer compatibility with both crane and forklift-based material handling approaches.

Based on SHJLPACK's experience with Mexican manufacturing layouts, we recommend conducting a thorough material flow simulation before deciding. The optimal configuration often depends on whether your primary constraint is total space availability or efficient material movement between processing stages.

3. Which Tilter Type Delivers Better ROI for Mexican Manufacturing Plants?

Leading Paragraph:

Michael needs to justify every equipment investment to corporate management with clear financial returns. The ROI calculation for coil tilting equipment involves multiple factors beyond the initial purchase price, including labor savings, productivity gains, and maintenance costs.

Snippet Paragraph:

For most Mexican metal processing plants, floor-mounted tilters deliver faster ROI (12-18 months) due to lower installation costs and flexibility. However, high-volume operations processing 150+ coils daily often achieve better long-term returns with pit-mounted systems (18-24 month ROI) through higher throughput and reduced operational expenses. SHJLPACK's analysis shows the breakpoint typically occurs at 120-150 coils per day.

Dive Deeper Content:

ROI Calculation Framework

Here's how to calculate the real return on investment for your specific operation:

Step 1: Calculate Current Manual Handling Costs

- Labor: 3 workers × $18,000/year = $54,000

- Productivity: 40-50 coils/hour manually vs 60-80 coils/hour automated

- Damage: 2-3% product damage rate manually vs 0.5-1% automated

- Typical annual savings: $85,000-120,000

| Step 2: Compare Equipment Scenarios | ROI Factor | Floor-Mounted | Pit-Mounted |

|---|---|---|---|

| Installation Cost | $55,000-75,000 | $75,000-100,000 | |

| Annual Labor Savings | $65,000-85,000 | $75,000-95,000 | |

| Throughput Increase | 25-35% | 35-45% | |

| Maintenance Costs | $3,000-5,000/year | $4,000-6,000/year | |

| Simple ROI Period | 12-18 months | 18-24 months |

Mexican Manufacturing Specific Factors

🇲🇽 Local Economic Considerations: Electricity costs, labor rates, and real estate values in Mexico create unique ROI calculations. Floor-mounted systems often show better returns in regions with lower space costs, while pit-mounted versions excel in high-rent industrial areas.

🏭 Production Volume Analysis: According to Randal Liu's experience with Mexican clients, the optimal choice changes dramatically based on daily production volumes:

- Under 80 coils/day: Floor-mounted delivers superior ROI

- 80-150 coils/day: Hybrid analysis required based on specific factors

- Over 150 coils/day: Pit-mounted typically provides better long-term value

⚡ Operational Efficiency Metrics: Beyond direct cost savings, consider these productivity impacts:

- Changeover time reduction: 40-50% with optimized layouts

- Quality improvement: 60-70% reduction in handling damage

- Safety enhancement: 80-90% reduction in manual handling injuries

SHJLPACK recommends conducting a detailed production analysis before deciding. Our team typically reviews 3-6 months of production data to model the exact ROI for each configuration based on your specific operational patterns and business objectives.

4. How Do Installation and Maintenance Requirements Differ Between Configurations?

Leading Paragraph:

The installation process and long-term maintenance needs significantly impact your operational continuity and total cost of ownership. Michael needs equipment that minimizes disruption during installation and ensures reliable performance with manageable maintenance demands.

Snippet Paragraph:

Floor-mounted coil tilters install in 3-5 days with minimal facility modifications, while pit-mounted versions require 2-3 weeks for excavation and foundation work. Maintenance accessibility is 40-60% better with floor-mounted designs, reducing service time by 2-3 hours per incident. According to SHJLPACK's service data, this translates to 15-25% lower annual maintenance costs for floor-mounted systems in typical Mexican industrial environments.

Dive Deeper Content:

Installation Process Comparison

Understanding the installation timeline and requirements helps plan production around the implementation:

Floor-Mounted Tilter Installation:

- Site Preparation (1-2 days): Level concrete foundation, utility connections

- Equipment Placement (1 day): Crane positioning, basic assembly

- Integration & Testing (1-2 days): Connection to power and control systems

- Operator Training (1 day): Basic operation and safety procedures

- Total time: 3-5 business days

- Production impact: Minimal (can often be scheduled around shifts)

Pit-Mounted Tilter Installation:

- Excavation & Foundation (5-8 days): Digging, reinforcement, concrete pouring, curing

- Drainage & Utilities (2-3 days): Water management systems, power connections

- Equipment Installation (3-4 days): Precise positioning in pit, assembly

- Commissioning & Training (2-3 days): System testing, operator certification

- Total time: 12-18 business days

- Production impact: Significant (often requires production line shutdown)

Maintenance Requirements Analysis

🔧 Routine Service Access: Floor-mounted tilters allow technicians to access all components from ground level, reducing service time by 40-50%. Pit-mounted units require confined space entry procedures, adding 30-45 minutes to each maintenance task.

🛠️ Component Replacement: Critical wear parts like hydraulic cylinders and sensors are 60-70% easier to replace in floor-mounted configurations. This difference becomes crucial during unexpected breakdowns when minimizing downtime is essential.

📊 Preventive Maintenance Scheduling: Based on SHJLPACK's maintenance records from Mexican clients:

- Floor-mounted: 4-6 hours monthly preventive maintenance

- Pit-mounted: 6-8 hours monthly plus quarterly deep cleaning

- Annual maintenance cost difference: $2,000-3,500 in favor of floor-mounted

According to Randal Liu, "The maintenance advantage of floor-mounted tilters often outweighs the space savings of pit-mounted versions for factories with limited technical staff. Easy access means problems get fixed faster, keeping your production line running smoothly."

Conclusion

Choosing between pit and floor-mounted coil tilters depends on your specific production volume, space constraints, and budget. Both configurations offer distinct advantages that can optimize your steel coil packing line efficiency and cost structure.

FAQ Section

Frequently Asked Questions

Q: Can I retrofit a floor-mounted tilter to pit-mounted configuration later?

A: Retrofitting is generally not cost-effective, as it requires complete disassembly, excavation, and reconstruction. The conversion cost typically exceeds 60-80% of purchasing a new pit-mounted system. It's better to choose the right configuration initially based on your long-term production forecasts.

Q: How does soil type affect pit-mounted tilter installation in Mexico?

A: Soil conditions significantly impact installation complexity and cost. Rocky soils common in northern Mexican industrial areas can increase excavation costs by 40-60%, while clay-heavy soils in central regions may require additional drainage and reinforcement. Always conduct a soil analysis before deciding on pit-mounted equipment.

Q: What safety features are critical for coil tilters in Mexican factories?

A: Essential safety features include emergency stop systems, anti-slip platforms, automatic locking during maintenance, and overload protection. SHJLPACK equipment includes CE-certified safety systems and meets Mexican NOM standards, with optional Spanish-language control interfaces and safety signage for local compliance.

Q: How long does typical installation take for each configuration?

A: Floor-mounted tilters typically install in 3-5 days with minimal disruption, while pit-mounted versions require 2-3 weeks for excavation and foundation work. The actual timeline depends on your site conditions, with Mexican industrial projects often facing additional 2-3 days for local permit processing and utility connections.

Q: Which Mexican industries benefit most from each tilter type?

A: Automotive and appliance manufacturers with high-volume production (150+ coils daily) often prefer pit-mounted tilters for maximum efficiency. Smaller metal service centers and fabrication shops typically choose floor-mounted versions for flexibility and faster ROI. SHJLPACK provides industry-specific recommendations based on your production patterns.