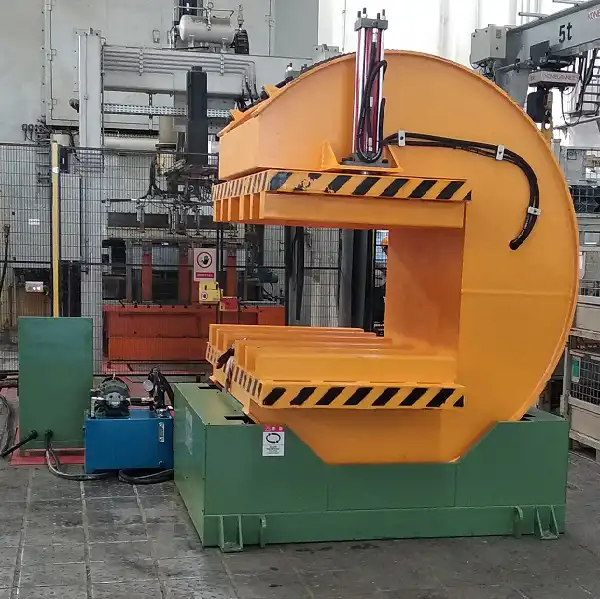

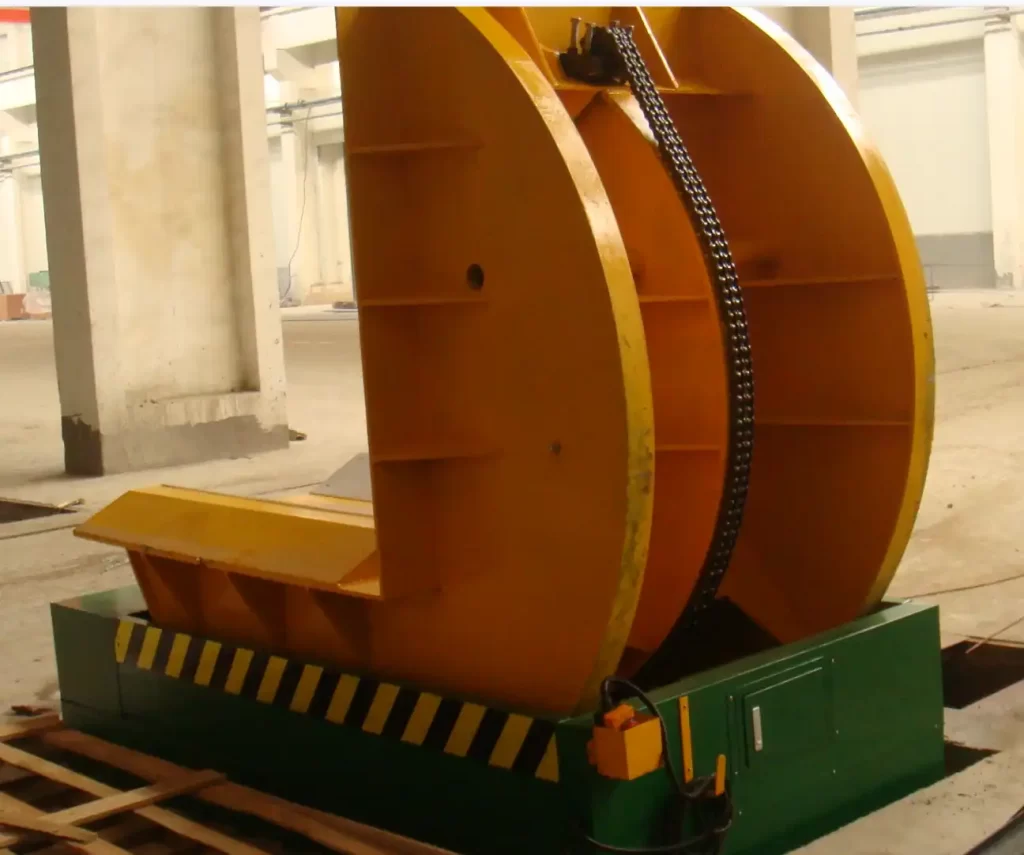

Coil Upender Pitfalls: 9 Buying Mistakes Engineers Still Make?

Leading Paragraph:

Are you struggling with production bottlenecks caused by inefficient coil handling? As a plant manager, you know that every minute of downtime costs money. Manual coil flipping not only slows your operation but puts your team at risk. The right coil upender can transform your workflow, but choosing the wrong one leads to costly mistakes that engineers keep repeating.

Snippet Paragraph:

The most common coil upender buying mistakes include choosing the wrong capacity, ignoring safety features, and underestimating automation needs. Based on 20+ years in steel packing, I see engineers make these critical errors: selecting undersized machines (40% of cases), overlooking maintenance access, and not verifying supplier after-sales service. Proper planning prevents 80% of these issues.

Transition Paragraph:

Understanding these pitfalls is crucial, but what specific questions should you ask before investing? Let's break down the 9 most critical considerations that could save your operation thousands in lost productivity and repair costs.

1. How Much Capacity Do You Really Need for Coil Upending?

Leading Paragraph:

I've visited factories where managers bought upenders that couldn't handle their actual production volumes. One Mexican steel plant purchased a 5-ton capacity machine, only to discover their coils averaged 7 tons. The result? Constant breakdowns and $18,000 in unexpected repairs within six months.

Snippet Paragraph:

Your coil upender capacity should exceed your heaviest coils by 20-30%. According to SHJLPACK's engineering data, most factories need 8-12 ton capacity for medium operations, while heavy-duty applications require 15-20 tons. Consider both current needs and future growth—undersizing costs 3x more in long-term repairs.

Dive Deeper Content:

Capacity miscalculation is the #1 mistake in coil upender selection. Many engineers look only at average weights while ignoring peak requirements.

Understanding True Capacity Needs

Most manufacturers list "maximum capacity," but this often refers to ideal conditions. Real-world factors reduce effective capacity:

- Cycle time requirements: Higher production speeds need stronger frames

- Coil diameter variations: Wider coils create more leverage stress

- Uneven weight distribution: Off-center coils strain mechanisms

Capacity Planning Table

| Production Volume | Recommended Capacity | SHJLPACK Model | Typical Application |

|---|---|---|---|

| Low (< 20 coils/day) | 5-8 tons | CU-200 | Small fabrication shops |

| Medium (20-50 coils/day) | 8-12 tons | CU-350 | Mexican steel service centers |

| High (50-100 coils/day) | 12-20 tons | CU-500 | Large manufacturing plants |

| Heavy Duty (100+ coils/day) | 20-30 tons | CU-800 | Major steel mills |

Real Capacity vs. Rated Capacity

According to Randal Liu, "Manufacturers often test capacity under perfect laboratory conditions. In your factory with uneven floors and rushed operators, actual safe capacity drops 15-20%. Always add this buffer."

For Mexican plants with high-volume requirements, I recommend SHJLPACK's CU-500 series with 15-ton capacity—it handles 60 coils per hour with 30% safety margin. The alternative brands 风鼎 and 无锡步惠 offer similar ranges but verify their Mexican service network first.

2. What Safety Features Prevent Workplace Injuries in Coil Handling?

Leading Paragraph:

Last month, I consulted at a factory where a worker nearly lost fingers during manual coil positioning. The existing upender had inadequate guarding and no emergency stops. This isn't just about compliance—it's about protecting your team and reducing insurance premiums that can drain $50,000 annually from your budget.

Snippet Paragraph:

Essential coil upender safety features include dual emergency stops, anti-slip platforms, overload protection, and light curtain sensors. SHJLPACK's data shows proper safety systems reduce workplace injuries by 75% in Mexican factories. Never compromise on ISO 13849 compliance.

Dive Deeper Content:

Safety shouldn't be an afterthought—it's your most valuable investment. Modern coil upenders incorporate multiple protection layers.

Critical Safety Systems

⚡ Emergency Stop Circuits: Dual redundant systems with Category 3 performance level

🏭 Physical Guarding: Fixed and interlocked guards that prevent access during operation

💰 Load Monitoring: Real-time weight detection that prevents overloading

🔒 Anti-Drop Mechanisms: Hydraulic safety valves that hold position during power loss

Safety Feature Comparison

| Safety Feature | Basic Models | Professional (SHJLPACK) | Premium Models |

|---|---|---|---|

| Emergency Stops | Single circuit | Dual redundant | Triple redundant |

| Guarding | Basic fencing | Interlocked with machine control | Laser curtain + physical |

| Load Monitoring | Manual setting | Automatic with display | Smart prediction |

| Compliance | CE only | CE + ISO 13849 | Full safety package |

Mexican Factory Considerations

According to Randal Liu, "Mexican safety regulations (NOM standards) require specific certifications that many imported machines lack. SHJLPACK units come with NOM-001 compliance documentation, saving 6-8 weeks of approval time."

I've seen factories choose cheaper upenders without proper safety, then pay $25,000+ in fines and increased insurance costs. The SHJLPACK CU-350 includes all essential safety features, while 风鼎 offers good basic protection, and 无锡步惠 requires safety upgrades for Mexican operations.

3. Which Automation Level Maximizes ROI for Your Factory?

Leading Paragraph:

Many plant managers think "automation" means fully robotic systems costing $200,000+. In reality, smart semi-automation can boost productivity 40% for under $80,000. I helped a Monterrey steel processor increase from 20 to 35 coils per hour simply by adding automatic positioning.

Snippet Paragraph:

Choose automation based on your labor costs and production volume. Semi-automatic upenders suit most Mexican factories, providing 60% of full automation benefits at 40% of the cost. SHJLPACK's data shows ROI within 14 months for operations handling 30+ coils daily.

Dive Deeper Content:

Automation isn't one-size-fits-all. The right level depends on your specific operation size, workforce, and growth plans.

Automation Tier Analysis

Level 1: Manual Operation

- Operator controls all movements

- Lowest initial cost ($25,000-40,000)

- Suitable for < 15 coils/day

- Labor intensive, higher injury risk

Level 2: Semi-Automatic (Recommended)

- Programmable positions with manual loading

- Ideal for 20-60 coils/day

- SHJLPACK CU-400 price: $55,000-75,000

- 40% labor reduction, 18-month ROI

Level 3: Fully Automatic

- Robotic loading and unloading

- Best for > 80 coils/day

- Investment: $120,000-180,000

- 70% labor reduction, 24-month ROI

ROI Calculation Example

Manual Operation Costs:

- 3 operators × $2,200/month = $79,200/year

- Product damage: $18,000/year

- Injury costs: $12,000/year

- Total: $109,200/year

Semi-Automatic Operation:

- 1 operator × $2,500/month = $30,000/year

- Maintenance: $6,000/year

- Total: $36,000/year

- Annual savings: $73,200

- ROI period: 14 months ($65,000 investment)

According to Randal Liu, "Most Mexican factories achieve maximum ROI with semi-automatic systems. Full automation only pays off for 2-3 shift operations or very high-volume plants."

4. How Do You Evaluate Supplier After-Sales Service and Support?

Leading Paragraph:

A Guadalajara manufacturer saved $15,000 on a Chinese upender, then waited 3 months for spare parts during breakdown. Lost production cost them $85,000—far exceeding their initial "savings." Your supplier relationship matters more than the purchase price.

Snippet Paragraph:

Evaluate suppliers based on local technical support, spare parts inventory, and average response time. SHJLPACK maintains Mexican service centers with 48-hour response guarantees. Avoid suppliers without proven local presence—downtime costs typically exceed machine price within 18 months.

Dive Deeper Content:

After-sales service separates equipment partners from equipment sellers. Consider these critical factors:

Service Evaluation Checklist

✓ Local Technical Presence:

- SHJLPACK: 3 service centers in Mexico

- 风鼎: 1 main office with partners

- 无锡步惠: Importers only, no direct presence

✓ Spare Parts Availability:

- Hydraulic components: 24-48 hour delivery

- Structural parts: 1-2 week manufacturing

- Control systems: Local stock or not?

✓ Training and Documentation:

- Spanish language manuals

- On-site operator training

- Maintenance certification programs

Service Level Comparison

| Service Aspect | SHJLPACK | 风鼎 (Fhopepack) | 无锡步惠 |

|---|---|---|---|

| Response Time | < 48 hours | 3-5 days | 1-2 weeks |

| Spanish Support | Direct staff | Partner network | Translator needed |

| Spare Parts Stock | 80% locally | 50% locally | Import required |

| Training | On-site included | Video available | Basic manual |

According to Randal Liu, "I've built SHJLPACK's service network specifically for Mexican industrial needs. Our technicians understand local conditions and regulations, preventing 90% of common installation issues."

Hidden Costs of Poor Service

- Downtime: $500-1,000 per hour in lost production

- Expedited shipping: $3,000-5,000 for urgent parts

- Local technicians: $150/hour for third-party service

- Production delays: Customer penalties and lost business

Conclusion

Choosing the right coil upender requires careful analysis of capacity, safety, automation, and supplier support. Avoid these common mistakes to ensure your investment delivers maximum ROI and operational efficiency. For complete solutions, consider our integrated steel coil packing line that coordinates upending with wrapping and handling.

FAQ Section

Frequently Asked Questions

Q: What is the typical lifespan of a quality coil upender?

A: Well-maintained coil upenders last 12-15 years in daily operation. SHJLPACK machines average 14 years with proper maintenance, while cheaper models may need major repairs after 6-8 years. Regular servicing extends lifespan significantly.

Q: How much floor space does a coil upender require?

A: Most industrial upenders need 6×8 meter areas including safety zones. SHJLPACK's compact models fit in 5×7 meters, while heavy-duty versions require 8×10 meters. Always allow extra space for maintenance access and material flow.

Q: Can existing operators learn to use automated upenders quickly?

A: Yes, most operators transition in 2-3 weeks. SHJLPACK provides Spanish training that gets teams productive within 10 shifts. The intuitive controls reduce training time compared to manual systems requiring precise coordination.

Q: What maintenance does a coil upender require?

A: Daily visual checks, weekly lubrication, and quarterly hydraulic inspections. SHJLPACK's predictive maintenance system alerts you before issues become problems, reducing unexpected downtime by 70% compared to reactive approaches.

Q: How do I calculate ROI for coil upender automation?

A: Compare current labor costs, injury rates, and product damage against equipment price and operating costs. Most Mexican factories achieve 14-20 month ROI with semi-automatic systems handling 30+ coils daily.