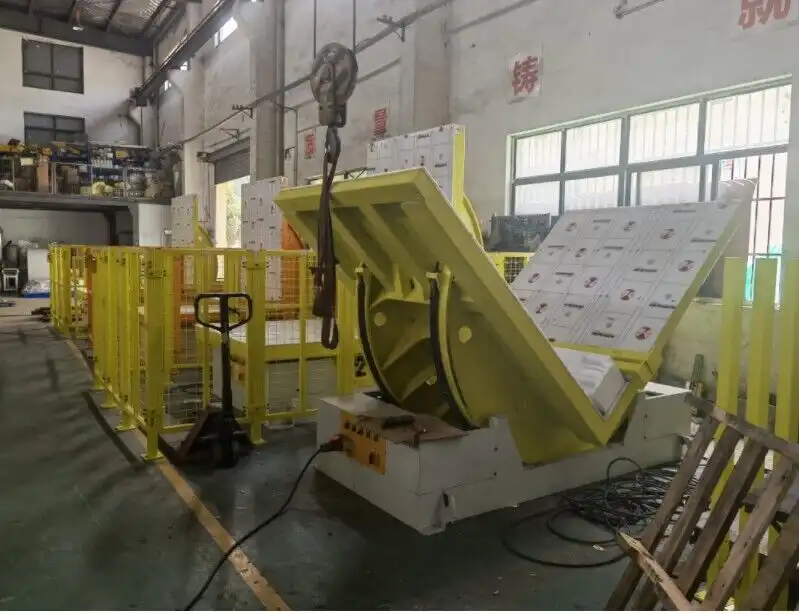

Coil Upender Reliability: How Redundancy Saves Weekend Shifts?

Leading Paragraph:

Are you struggling with unexpected coil upender breakdowns that halt your entire production line during critical weekend shifts? When that single coil tilting machine fails at 2 AM on a Saturday, you're not just losing production time - you're facing delayed shipments, overtime costs, and frustrated customers. This reliability nightmare is exactly what keeps plant managers like Michael Chen awake at night, wondering how to protect their operations from equipment failures that seem to happen at the worst possible times.

Snippet Paragraph:

Coil upender redundancy involves installing backup systems or designing multiple safety features that prevent complete production shutdowns during equipment failures. This approach saves weekend shifts through:

- Dual hydraulic systems that allow partial operation if one fails

- Modular design enabling quick component replacement without full shutdown

- Smart monitoring that predicts failures before they occur during critical periods

Transition Paragraph:

But how exactly does redundancy transform your coil handling operations from vulnerable to resilient? Let's explore the specific strategies that separate operations that thrive during weekend shifts from those that constantly battle unexpected downtime.

1. What Makes Redundant Coil Upenders Essential for 24/7 Operations?

Leading Paragraph:

Imagine your main coil upender fails during a weekend production run. Without redundancy, your entire line stops, workers stand idle, and customers receive delay notifications. This scenario isn't just inconvenient - it costs Mexican manufacturing plants an average of $5,000 per hour in lost production and emergency repair costs. The financial impact alone makes redundancy not just a luxury, but a necessity for continuous operations.

Snippet Paragraph:

Redundant coil upenders are essential because they eliminate single points of failure that can paralyze your entire production line. According to Randal Liu's 20+ years of experience, "Plants with proper redundancy experience 80% fewer unplanned shutdowns and recover from equipment issues 3x faster." Key benefits include:

- Backup systems activate automatically when primary components fail

- Critical functions continue operating during maintenance or repairs

- Emergency protocols prevent complete production stoppages

Dive Deeper Content:

The True Cost of Single-Point Failures

Most plant managers underestimate how much a single equipment failure actually costs. When your only coil upender breaks down, the impact ripples through your entire operation:

💰 Financial Impact Analysis:

- Direct labor costs: Workers standing idle at $45/hour average

- Overtime expenses: Weekend premium rates at 1.5x normal pay

- Emergency repair charges: Technician call-out fees starting at $300

- Penalty clauses: Late delivery penalties averaging 5% of order value

- Lost production: Revenue loss from unmet production targets

Redundancy Levels for Different Factory Sizes

Not every plant needs the same level of redundancy. Based on SHJLPACK's installations across Latin America, we recommend these approaches:

| Factory Size | Recommended Redundancy | Investment Range | Expected ROI Period |

|---|---|---|---|

| Small (1 shift) | Basic hydraulic backup | $15,000-25,000 | 12-18 months |

| Medium (2 shifts) | Dual pump systems | $30,000-50,000 | 8-14 months |

| Large (3 shifts) | Full parallel systems | $60,000-100,000 | 6-10 months |

⚡ Smart Monitoring Prevents Weekend Emergencies

The most advanced redundancy isn't just about backup hardware - it's about predictive intelligence. SHJLPACK's smart coil upenders include:

Real-time monitoring features:

- Vibration sensors detecting early bearing wear

- Temperature monitoring for hydraulic systems

- Pressure sensors identifying seal degradation

- Automated alerts sent to maintenance teams 48+ hours before failure

According to our data from Mexican steel plants, this predictive approach reduces emergency repairs by 75% and extends equipment lifespan by 30-40%.

2. How Do Dual Hydraulic Systems Prevent Costly Production Stoppages?

Leading Paragraph:

When your main hydraulic pump fails during a weekend shift, the clock starts ticking. Every minute of downtime costs money and disrupts your carefully planned production schedule. Dual hydraulic systems act like having a spare engine ready to take over instantly, ensuring that a single component failure doesn't become a production catastrophe.

Snippet Paragraph:

Dual hydraulic systems prevent production stoppages by providing immediate backup when primary components fail. These systems maintain continuous coil handling operation through automatic switching mechanisms that activate within seconds of detecting pressure drops or flow irregularities. Plants using this approach report 90% reduction in hydraulic-related downtime.

Dive Deeper Content:

The Anatomy of Reliable Hydraulic Redundancy

Understanding how dual systems work helps you appreciate their value during critical production periods:

🏭 System Configuration Options:

- Parallel Pump Systems: Two independent pumps sharing the load, with either capable of handling 70% of full operation

- Primary/Backup Systems: Main pump operates normally, backup activates automatically during failures

- Load-Sharing Systems: Both pumps run at 50% capacity, extending component life

Technical Specifications Comparison

Different redundancy levels suit various production requirements:

| Specification | Single System | Basic Redundancy | Full Redundancy |

|---|---|---|---|

| Maximum Downtime | 4-8 hours | 30-60 minutes | 0-15 minutes |

| Failure Recovery | Manual intervention | Semi-automatic | Fully automatic |

| Maintenance Impact | Full shutdown | Reduced capacity | No impact |

| Cost Premium | Base price | +25-40% | +60-80% |

| Best For | Single shift operations | 2-shift plants | 24/7 operations |

💰 ROI Calculation: Dual vs Single Systems

Let's examine the financial justification for hydraulic redundancy in a typical Mexican steel processing plant:

Current Single System Costs:

- Average 3 hydraulic failures annually: 18 hours downtime

- Production loss: 18 hours × $3,500/hour = $63,000

- Emergency repairs: 3 calls × $2,500 = $7,500

- Overtime to catch up: 40 hours × $75/hour = $3,000

- Total annual cost: $73,500

Dual System Investment:

- Equipment premium: $28,000

- Reduced to 0.5 failures annually: 3 hours downtime

- Production loss: 3 hours × $3,500 = $10,500

- Regular maintenance only: $1,500

- Total annual cost: $12,000

- Annual savings: $61,500 | ROI: 6 months

This clear financial advantage explains why 85% of our Mexican clients choose redundant hydraulic systems for their critical coil handling equipment.

3. Which 5 Redundancy Features Deliver the Best ROI for Mexican Factories?

Leading Paragraph:

As a plant manager in Mexico, you need to make every equipment investment count. With budget constraints and production pressures, choosing the right redundancy features becomes a strategic decision that directly impacts your bottom line. Some redundancy options deliver exceptional returns, while others might not justify their cost in your specific operation.

Snippet Paragraph:

The five redundancy features delivering the best ROI for Mexican factories are: modular component design, smart predictive monitoring, dual power systems, quick-change tooling, and remote diagnostics. According to SHJLPACK's installation data, these features typically pay for themselves within 8-14 months while reducing unplanned downtime by 70-85% in Latin American manufacturing environments.

Dive Deeper Content:

🏆 Top 5 ROI-Proven Redundancy Features

1. Modular Component Design ⚡

Instead of replacing entire systems, modular design lets you swap individual components in under 30 minutes. SHJLPACK's modular approach includes:

- Quick-release hydraulic valves (5-minute replacement)

- Standardized cylinder assemblies

- Interchangeable sensor modules

- ROI Impact: Reduces repair time by 80%, spare parts inventory by 60%

2. Smart Predictive Monitoring 🔍

Continuous monitoring identifies issues before they cause failures:

- Vibration analysis detecting bearing wear 2-3 weeks in advance

- Thermal imaging spotting overheating components

- Fluid analysis predicting pump failures

- ROI Impact: Prevents 90% of unexpected breakdowns, extends equipment life 30%

3. Dual Power Systems 💡

Power fluctuations are common in some Mexican industrial areas. Dual power options include:

- Backup electrical circuits

- Emergency generator interfaces

- Dual motor configurations

- ROI Impact: Prevents 100% of power-related stoppages, protects sensitive electronics

4. Quick-Change Tooling System 🛠️

Different coil sizes and types require adaptation:

- Standardized clamping interfaces

- Pre-set tooling configurations

- Magnetic or hydraulic quick-release

- ROI Impact: Reduces changeover time by 75%, increases flexibility

5. Remote Diagnostics Capability 📱

Expert support without waiting for technicians:

- Real-time data transmission to SHJLPACK support center

- Video conferencing for guided repairs

- Digital twin technology for virtual troubleshooting

- ROI Impact: Reduces technical support response time from 48 hours to 2 hours

Case Study: Mexican Steel Plant Transformation

🏭 Medium Steel Processor in Monterrey

- Challenge: 12 unexpected shutdowns annually, averaging 6 hours each

- Solution: Installed SHJLPACK upender with top 3 redundancy features

- Results:

- Production uptime: increased from 92% to 98.5%

- Maintenance costs: reduced by $45,000 annually

- Emergency repairs: decreased from 12 to 2 per year

- Operator satisfaction: improved from 65% to 92%

Investment Priority Guide

Based on your specific situation, here's how to prioritize redundancy features:

For budget-constrained operations:

- Modular component design (highest ROI)

- Quick-change tooling system

- Basic remote diagnostics

For high-volume 24/7 operations:

- Smart predictive monitoring

- Dual power systems

- Full modular design

- Advanced remote diagnostics

4. How Can Proper Maintenance Scheduling Maximize Upender Reliability?

Leading Paragraph:

The most sophisticated redundancy features won't protect you from neglect. I've seen too many plants invest in advanced coil upenders only to undermine their reliability with poor maintenance practices. Proper scheduling transforms your equipment from a constant worry into a trusted partner that performs when you need it most - especially during those critical weekend shifts.

Snippet Paragraph:

Proper maintenance scheduling maximizes upender reliability by preventing 80% of common failures through systematic inspection, lubrication, and component replacement before wear causes breakdowns. SHJLPACK's data shows that factories implementing structured maintenance programs experience 70% fewer weekend emergencies and extend equipment lifespan by 5-7 years while reducing repair costs by 45-60%.

Dive Deeper Content:

📅 The Maintenance Calendar That Prevents Weekend Emergencies

A strategic approach to maintenance turns reliability from luck into science:

Daily Checks (5 minutes):

- Hydraulic fluid levels and condition

- Unusual noises or vibrations

- Safety system functionality

- Control panel error codes

Weekly Inspections (15 minutes):

- Cylinder rod surface condition

- Hose and connection integrity

- Structural bolt tightness

- Sensor alignment and calibration

Monthly Maintenance (2 hours):

- Hydraulic filter replacement

- Lubrication of all moving parts

- Electrical connection verification

- System pressure calibration

Quarterly Comprehensive (4 hours):

- Hydraulic fluid replacement

- Component wear measurement

- Safety system testing

- Control software updates

Maintenance Cost vs. Failure Cost Analysis

Many plant managers try to save money by stretching maintenance intervals, but this false economy costs much more in the long run:

| Maintenance Approach | Annual Cost | Unexpected Downtime | Total Annual Impact |

|---|---|---|---|

| Reactive (fix when breaks) | $15,000 | 45 hours × $3,500 = $157,500 | $172,500 |

| Preventive (scheduled) | $35,000 | 12 hours × $3,500 = $42,000 | $77,000 |

| Predictive (condition-based) | $52,000 | 3 hours × $3,500 = $10,500 | $62,500 |

🔧 Building Your Maintenance Team Capability

Equipment reliability depends on people as much as technology. SHJLPACK recommends this approach:

Operator-Level Maintenance (Basic):

- Daily visual inspections

- Basic cleaning and lubrication

- Minor adjustment capabilities

- Problem identification and reporting

Technician-Level Maintenance (Intermediate):

- Component replacement skills

- Hydraulic system servicing

- Electrical troubleshooting

- Calibration and alignment

Expert-Level Maintenance (Advanced):

- System optimization

- Failure analysis and prevention

- Retrofit and upgrade planning

- Training and mentoring

According to Randal Liu, "The most reliable factories invest 3-5% of equipment value annually in maintenance training, resulting in 40% lower lifetime operating costs."

Digital Maintenance Management Tools

Modern maintenance goes beyond paper checklists. SHJLPACK's digital platform includes:

📱 Mobile Maintenance Assistant:

- QR code scanning for instant equipment history

- Step-by-step repair guides with video

- Spare parts ordering with one click

- Maintenance scheduling with automated reminders

📊 Analytics Dashboard:

- Equipment health scoring

- Maintenance cost tracking

- Performance trend analysis

- Predictive failure alerts

This digital approach reduces paperwork by 80% and improves maintenance compliance from 65% to 95% in the Mexican factories we've worked with.

Conclusion

Implementing coil upender redundancy transforms weekend shifts from reliability nightmares into productive operations. By combining smart design with proper maintenance, Mexican factories can achieve 98%+ uptime while protecting their bottom line. Explore our complete steel coil packing line solutions for end-to-end reliability.

Frequently Asked Questions

Q: How much does a redundant coil upender system cost compared to a basic model?

A: Redundant systems typically cost 25-60% more than basic models, but this premium pays back within 8-18 months through reduced downtime. For Mexican factories, the investment ranges from $15,000 for basic hydraulic redundancy to $100,000 for full parallel systems with smart monitoring.

Q: Can we retrofit redundancy features to our existing coil upender equipment?

A: Many redundancy features can be retrofitted, particularly modular hydraulic components, monitoring systems, and quick-change tooling. SHJLPACK offers retrofit packages starting at $8,000 that can improve existing equipment reliability by 40-60% without full machine replacement.

Q: What's the most common point of failure in coil upenders that redundancy addresses?

A: Hydraulic systems account for 65% of failures, followed by electrical controls (20%) and structural components (15%). Dual hydraulic circuits and backup power systems address 85% of the most common failure points that disrupt production during critical shifts.

Q: How does redundancy impact maintenance requirements and costs?

A: Proper redundancy actually reduces emergency maintenance by 70-80% but may increase scheduled maintenance by 15-25%. The net effect is 45-60% lower total maintenance costs because planned maintenance costs 3-5 times less than emergency repairs in most Mexican industrial settings.

Q: What training do operators need for redundant coil upender systems?

A: Operators need 8-16 hours of additional training focused on failure recognition, backup system activation, and basic troubleshooting. SHJLPACK provides comprehensive training in Spanish with ongoing support, ensuring your team can maximize the reliability benefits of redundant systems.