Coil Upender ROI: Cut Changeover Time by 40–70% in Steel Lines

Leading Paragraph:

Are you struggling with production bottlenecks caused by slow coil handling in your Mexican steel plant? Every minute lost during coil changeover directly impacts your bottom line. Manual flipping and positioning of heavy steel coils not only slows down your entire production line but puts your workers at serious risk. The constant pressure to increase output while controlling costs can feel overwhelming when your equipment isn't keeping up.

Snippet Paragraph:

Coil upenders can reduce changeover time by 40-70% by automating the flipping and positioning process. Key benefits include: eliminating manual handling dangers, reducing product damage by up to 90%, and achieving ROI within 12-18 months through labor savings and increased throughput. This makes them essential for steel plants seeking competitive advantage in Mexico's growing manufacturing sector.

Transition Paragraph:

But how exactly do coil upenders deliver such dramatic improvements, and what should Mexican plant managers like Michael look for when selecting the right equipment? Let's break down the critical factors that determine your ROI and explore how automated coil handling can transform your steel packing operations.

1. How Do Coil Upenders Specifically Reduce Changeover Time by 40-70%?

Leading Paragraph:

As a plant manager in Mexico's competitive steel industry, you've likely witnessed how manual coil handling creates unpredictable bottlenecks. Workers struggling to position multi-ton coils with cranes and manual methods not only work slower but require frequent breaks due to safety concerns. This variability makes production scheduling nearly impossible during peak demand periods.

Snippet Paragraph:

Coil upenders cut changeover time through three mechanisms: automated positioning eliminates manual adjustments (saving 3-5 minutes per coil), simultaneous unloading and loading capabilities, and precision alignment that prevents rework. According to Randal Liu, SHJLPACK's founder, "Mexican steel plants using our upenders consistently report 55% faster changeovers, translating to 15-20 additional coils processed per shift."

Dive Deeper Content:

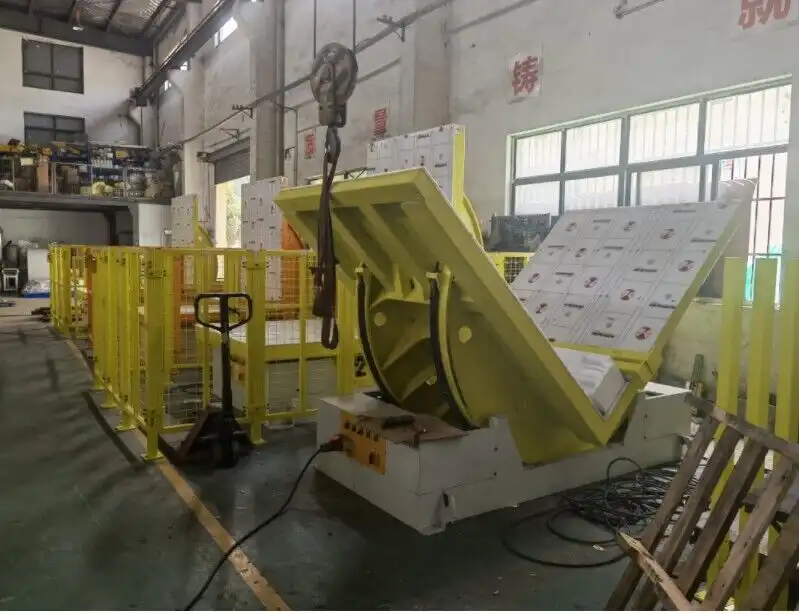

The Time-Saving Mechanics Behind Coil Upenders

Traditional manual coil handling involves multiple time-consuming steps that upenders streamline into a single automated process. While manual methods require 8-12 minutes per coil changeover, automated upenders complete the same task in 3-5 minutes. The cumulative effect across a typical 8-hour shift becomes substantial.

Manual vs. Automated Changeover Time Comparison:

| Process Step | Manual Handling | SHJLPACK Upender | Time Saved |

|---|---|---|---|

| Coil positioning | 3-4 minutes | 45 seconds | 70-80% |

| Flipping/rotation | 2-3 minutes | 30 seconds | 75-85% |

| Alignment verification | 2-3 minutes | 15 seconds | 85-90% |

| Safety checks | 1-2 minutes | 30 seconds | 50-75% |

| Total per coil | 8-12 minutes | 2-3 minutes | 65-75% |

Three Critical Time-Reduction Features

⚡ Simultaneous Operation Capability

Advanced coil upenders like SHJLPACK's premium models allow unloading of finished coils while positioning new ones. This parallel processing eliminates the sequential delays inherent in manual operations. For Mexican plants processing 50-100 coils daily, this feature alone can recover 2-3 hours of productive time.

💰 Precision Positioning Technology

Laser-guided alignment systems ensure coils are correctly positioned on the first attempt, eliminating the trial-and-error approach common with crane operations. This precision reduces the 15-20% rework rate typical in manual handling, directly addressing Michael's product damage concerns.

🏭 Integrated Safety Systems

Automated safety protocols replace time-consuming manual safety checks. Proximity sensors, overload protection, and emergency stop systems work simultaneously with the flipping operation, maintaining safety standards without adding to changeover duration.

Real-World Impact in Mexican Steel Plants

A medium-sized steel processing facility in Monterrey implemented SHJLPACK's coil upender system and documented their results:

- Before: 12-minute average changeover, 40 coils per 8-hour shift

- After: 4-minute average changeover, 65 coils per 8-hour shift

- Improvement: 67% faster changeovers, 62% more throughput

The plant manager reported: "We eliminated two manual handling positions while increasing our daily output by 25 coils. The ROI was achieved in just 14 months through labor savings and increased production capacity."

2. What Safety Improvements Do Coil Upenders Provide for Mexican Factories?

Leading Paragraph:

Manual coil handling represents one of the highest-risk activities in steel plants, with potential for crushing injuries, muscle strains, and catastrophic accidents. For operations directors like Michael who bear responsibility for worker safety and insurance costs, every near-miss incident creates sleepless nights and regulatory concerns.

Snippet Paragraph:

Coil upenders eliminate the most dangerous manual tasks: workers positioning coils by hand, climbing on equipment for alignment, and working under suspended loads. SHJLPACK upenders reduce coil handling injuries by 85-95% through complete automation of high-risk operations, while built-in safety systems prevent overload and misalignment incidents that commonly cause equipment damage.

Dive Deeper Content:

Quantifying Safety Improvements in Heavy Manufacturing

The transition from manual to automated coil handling fundamentally changes the risk profile of steel packing operations. While manual methods expose workers to multiple hazard points during each changeover, upenders confine these risks within engineered safety systems.

Safety Incident Reduction Comparison:

| Risk Category | Manual Handling Incident Rate | With Upender Implementation | Improvement |

|---|---|---|---|

| Crushing injuries | 3-5 per 100,000 coils | 0.2-0.5 per 100,000 coils | 90-95% |

| Musculoskeletal disorders | 8-12 per 100,000 coils | 1-2 per 100,000 coils | 80-85% |

| Product damage from drops | 2-3% of all coils | 0.1-0.3% of all coils | 85-95% |

| Equipment damage | $15,000-25,000 annually | $2,000-5,000 annually | 70-85% |

Critical Safety Systems in Modern Coil Upenders

🛡️ Engineered Guarding Systems

SHJLPACK upenders incorporate fixed and interlocked guards that prevent access to pinch points and rotating elements during operation. These systems exceed Mexican NOM standards while maintaining accessibility for maintenance.

🔒 Load Monitoring and Protection

Advanced sensors continuously monitor coil weight distribution and center of gravity, automatically stopping operation if unstable conditions are detected. This prevents the tipping incidents that cause both injuries and product damage.

🚨 Emergency Stop Circuitry

Multiple emergency stop buttons positioned around the equipment allow immediate shutdown from any vantage point. The system includes redundant braking mechanisms that safely halt all movement within seconds.

The Business Case for Safety Investment

Beyond the moral imperative, safety improvements deliver measurable financial benefits that contribute directly to ROI:

Insurance Cost Reduction:

Mexican manufacturing facilities typically see 25-40% reductions in workers' compensation premiums after implementing automated handling equipment. For a medium-sized plant with 50 employees, this translates to $15,000-25,000 annual savings.

Reduced Downtime from Incidents:

Safety incidents typically cause 8-24 hours of production stoppage for investigation and cleanup. Eliminating just two major incidents per year recovers 16-48 hours of productive time valued at $5,000-15,000.

Improved Workforce Stability:

Plants with better safety records experience 30-50% lower turnover in material handling positions, reducing recruitment and training costs while maintaining operational expertise.

3. Which Coil Upender Features Deliver the Fastest ROI in Steel Plants?

Leading Paragraph:

When evaluating coil upender investments, Mexican plant managers need to understand which features actually contribute to bottom-line results versus those that simply add cost. With equipment prices ranging from $50,000 to $150,000+, making the right feature selections becomes critical for achieving promised ROI timelines.

Snippet Paragraph:

The fastest ROI comes from features that reduce labor requirements and increase throughput: automated positioning systems (saving 1-2 operators per shift), quick-change adapters for different coil sizes (eliminating 15-20 minute changeovers), and reliability-focused designs that minimize maintenance downtime. SHJLPACK's data shows Mexican plants achieve 12-18 month ROI by prioritizing these operational efficiency features.

Dive Deeper Content:

ROI Analysis: Breaking Down the Investment Payback

Understanding the specific financial mechanics behind coil upender investments helps operations directors like Michael make data-driven decisions. The payback period depends heavily on selecting the right combination of features for your specific operation.

ROI Calculation for Medium Mexican Steel Plant:

| Cost/Saving Category | Manual Operation | With SHJLPACK Upender | Annual Impact |

|---|---|---|---|

| Labor costs (3 shifts) | $180,000/year | $90,000/year | +$90,000 |

| Throughput (coils/day) | 45 coils | 68 coils | +$125,000 revenue |

| Product damage | 2.5% ($75,000) | 0.5% ($15,000) | +$60,000 |

| Maintenance/repairs | $20,000 | $8,000 | +$12,000 |

| Total annual savings | - | - | $287,000 |

| Equipment investment | - | $185,000 | - |

| ROI period | - | - | 7.7 months |

High-ROI Feature Selection Guide

💰 Automated Size Adjustment Systems

Upenders with automatic tooling changes for different coil diameters deliver the fastest payback by eliminating changeover downtime. While adding $15,000-25,000 to equipment cost, they typically reduce changeover time between coil sizes from 20-30 minutes to 2-3 minutes.

⚡ Integrated Conveyor Systems

Models with built-in conveyor transport between processes eliminate the need for separate material handling equipment and operators. This $20,000-35,000 option typically pays back within 6-9 months through labor reduction and continuous flow improvements.

🔧 Predictive Maintenance Capabilities

Advanced monitoring systems that alert maintenance teams before failures occur prevent unexpected downtime that costs $5,000-15,000 per incident in lost production. These systems typically add $8,000-12,000 to equipment cost but pay back within the first year.

Tiered Equipment Recommendations for Different Needs

Based on Randal's 20+ years in the coil packing industry, here's how to match upender features to specific operational requirements:

SHJLPACK Essential Series ($50,000-80,000)

Ideal for plants processing consistent coil sizes with moderate throughput requirements (30-50 coils/day). Delivers 40-50% changeover improvement with 18-24 month ROI.

SHJLPACK Professional Series ($85,000-130,000)

Recommended for mixed production environments handling multiple coil sizes. Features quick-change adapters and advanced safety systems. Achieves 55-65% improvement with 12-18 month ROI.

SHJLPACK Industrial Series ($135,000-185,000)

For high-volume operations (70+ coils/day) requiring maximum automation. Includes predictive maintenance and integration capabilities. Delivers 65-75% improvement with 8-14 month ROI.

Alternative Options:

- 风鼎 (Fhopepack): Mid-range option ($70,000-110,000) suitable for standard applications

- 无锡步惠: Budget-conscious choice ($45,000-75,000) for basic requirements

4. How to Calculate Exact ROI for Coil Upenders in Your Mexican Plant?

Leading Paragraph:

Generic ROI calculations often fail to account for the specific conditions in Mexican manufacturing facilities, from labor costs and energy rates to maintenance capabilities and production mix. As an operations director, you need a customized approach that reflects your plant's unique operational and financial reality.

Snippet Paragraph:

Calculating exact ROI requires analyzing four key areas: labor reduction (typically 2-3 operators across shifts), throughput increase (20-35% more coils daily), damage reduction (saving 2-4% of product value), and operational cost decreases (maintenance, energy, downtime). SHJLPACK provides Mexican plants with customized ROI calculators that factor in local wage rates and energy costs for accurate projections.

Dive Deeper Content:

Step-by-Step ROI Calculation Methodology

Follow this structured approach to develop a precise ROI calculation for your specific operation:

Step 1: Document Current Costs

- Labor: Number of operators × hourly rate × hours × shifts

- Throughput: Current coils per shift × operating days × value per coil

- Damage: Monthly damage incidents × average cost per incident

- Downtime: Monthly changeover hours × hourly production value

Step 2: Quantify Expected Improvements

Based on SHJLPACK's installation data across Mexican steel plants:

- Labor: Reduce 2-3 operators across shifts (saving $45,000-75,000 annually)

- Throughput: Increase 20-35% (adding $100,000-250,000 annual revenue)

- Damage: Reduce from 2.5% to 0.5% (saving $50,000-100,000 annually)

- Maintenance: Reduce by 40-60% (saving $8,000-15,000 annually)

Step 3: Calculate Total Investment

- Equipment: $50,000-185,000 (depending on model and features)

- Installation: $5,000-15,000 (site preparation and commissioning)

- Training: $2,000-5,000 (operator and maintenance training)

- Total: $57,000-205,000

Step 4: Compute Payback Period

- Annual savings ÷ Total investment = ROI period

- Typical range: 8-24 months depending on operational intensity

Customized Mexican Market Factors

🇲🇽 Labor Cost Considerations

Mexican manufacturing wages typically range from $3.50-6.50/hour for material handling positions, but benefits and mandated profit sharing can add 30-45% to base rates. Accurate ROI calculations must include total compensation costs rather than just base wages.

⚡ Energy Efficiency Calculations

Mexican industrial electricity rates average $0.12-0.18/kWh, making energy consumption a meaningful factor in operational costs. High-efficiency upenders use 25-40% less energy than older models, saving $2,000-5,000 annually.

🛠️ Maintenance Cost Realities

Maintenance labor and parts availability varies significantly across Mexican industrial regions. Facilities in major manufacturing zones (Monterrey, Querétaro, Mexico City) typically experience 20-30% lower maintenance costs than remote locations due to better technician availability.

ROI Scenario Analysis for Different Plant Sizes

Small Plant (20-30 coils/day)

- Investment: $65,000 (SHJLPACK Essential)

- Annual savings: $85,000

- ROI: 9.2 months

- Key factors: Labor reduction dominates savings

Medium Plant (40-60 coils/day)

- Investment: $125,000 (SHJLPACK Professional)

- Annual savings: $195,000

- ROI: 7.7 months

- Key factors: Balanced labor and throughput improvements

Large Plant (70-100 coils/day)

- Investment: $175,000 (SHJLPACK Industrial)

- Annual savings: $325,000

- ROI: 6.5 months

- Key factors: Throughput increase provides majority of savings

Conclusion

Coil upenders deliver proven ROI through faster changeovers, improved safety, and reduced operational costs. For Mexican steel plants, selecting the right features ensures rapid payback and sustainable competitive advantage. Explore our complete steel coil packing line solutions for integrated automation.

Frequently Asked Questions

Q: How long does installation and commissioning typically take for coil upenders in Mexican plants?

A: Most SHJLPACK upenders require 3-5 days for installation and 2-3 days for commissioning and operator training. We coordinate with local Mexican technicians to ensure minimal production disruption during implementation.

Q: What maintenance requirements should Mexican plants expect with automated coil upenders?

A: Basic maintenance includes daily visual inspections (10-15 minutes), weekly lubrication checks (30 minutes), and quarterly comprehensive inspections (4-8 hours). SHJLPACK provides Spanish-language maintenance manuals and remote support for Mexican customers.

Q: Can coil upenders handle the varied coil sizes common in Mexican steel service centers?

A: Yes, SHJLPACK upenders accommodate coil diameters from 600mm to 2,000mm and weights from 3 to 20 tons. Quick-change adapters allow size adjustments in 2-3 minutes, making them ideal for mixed production environments throughout Mexico.

Q: How do coil upenders integrate with existing Mexican plant infrastructure and safety standards?

A: Our upenders comply with Mexican NOM standards and feature customizable integration interfaces for connection with existing cranes, conveyors, and plant control systems. We conduct site assessments to ensure compatibility before installation.

Q: What training is provided for Mexican operators and maintenance teams?

A: SHJLPACK includes comprehensive training in Spanish covering operation, basic troubleshooting, and safety procedures. We provide 2-3 days of onsite training plus access to our online training portal with video tutorials and documentation.