Coil Upender Load Handling: Pallet, Saddle, or Mandrel—What to Choose?

Leading Paragraph:

Are you struggling with slow, dangerous coil handling in your Mexican metal processing plant? Every minute your team manually flips heavy steel coils represents not just efficiency loss, but serious safety risks and potential product damage. As a plant manager like Michael Chen, you need solutions that eliminate bottlenecks while protecting both your workers and your bottom line.

Snippet Paragraph:

The optimal coil upender choice depends on your specific operation: pallet upenders for standard coils under 10 tons, saddle upenders for heavy-duty applications up to 20 tons, and mandrel upenders for delicate or specialty materials. Key selection factors include: coil weight and diameter, production speed requirements, available floor space, and automation level needed. For Mexican steel plants, saddle upenders typically offer the best balance of durability and cost-effectiveness.

Transition Paragraph:

Choosing the wrong upender type can cost your factory thousands in downtime and maintenance. Let me guide you through the critical decision factors based on 20+ years of coil packing experience, so you can select equipment that truly matches your Mexican plant's operational needs.

1. What Are the 3 Main Types of Coil Upenders and Their Core Applications?

Leading Paragraph:

When I first started working with Mexican steel processors, I saw many plants using the wrong upender type for their specific coils. This mismatch caused constant breakdowns, safety incidents, and frustrated managers like Michael. Understanding these three fundamental upender designs is your first step toward making an informed investment.

Snippet Paragraph:

The three primary coil upender types serve distinct purposes: pallet upenders handle standard coils up to 10 tons with excellent stability, saddle upenders manage heavy coils up to 20 tons with superior weight distribution, and mandrel upenders protect delicate materials using internal support systems. According to Randal Liu, SHJLPACK's founder, "90% of Mexican steel plants should start with saddle upenders—they handle the weight range most commonly processed while offering the durability needed for high-volume operations."

Dive Deeper Content:

Pallet Upenders: The Workhorse for Standard Operations

Pallet upenders use a platform-based design that lifts and rotates coils safely. They're ideal for Mexican plants processing coils up to 10 tons with diameters between 800-1800mm. The SHJLPACK PU-1000 model, for example, handles 8-10 coils per hour with 7.5kW power consumption—perfect for medium-volume operations.

Key Advantages:

✓ Lower initial investment (typically $25,000-40,000)

✓ Easy integration with existing conveyor systems

✓ Minimal floor space requirements

✓ Suitable for various coil materials including steel, aluminum, and copper

Limitations:

⚡ Maximum capacity typically 10 tons

⚡ Not ideal for oversized or irregularly shaped coils

⚡ May require additional stabilization for very dense materials

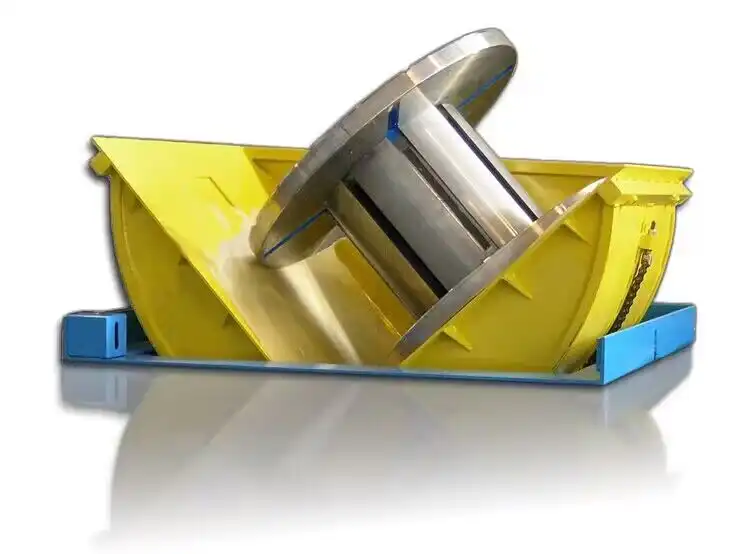

Saddle Upenders: Heavy-Duty Champions

Saddle upenders feature a curved support system that cradles coils during rotation. This design distributes weight more evenly, making them perfect for Mexican heavy steel processors. The SHJLPACK SU-2000 handles up to 20 tons with 15-20 coils per hour capacity—exactly what high-volume plants need.

| Technical Specifications Comparison: | Feature | Pallet Upender | Saddle Upender | Mandrel Upender |

|---|---|---|---|---|

| Max Capacity | 10 tons | 20 tons | 15 tons | |

| Typical Speed | 8-12 coils/h | 15-20 coils/h | 10-15 coils/h | |

| Power Requirement | 7.5-11 kW | 15-22 kW | 11-18.5 kW | |

| Floor Space | 15-20 m² | 20-30 m² | 18-25 m² | |

| Best For | Standard coils | Heavy steel coils | Delicate materials |

Mandrel Upenders: Precision for Specialty Materials

Mandrel upenders use an internal shaft that inserts into the coil core, providing exceptional stability for delicate materials like precision steel strips or coated coils. While less common in standard Mexican steel plants, they're essential for operations handling high-value products where edge damage means significant financial loss.

Application Scenarios:

🏭 Automotive Steel Processor in Monterrey

- Challenge: Coated steel coils suffering edge damage during manual handling

- Solution: SHJLPACK MU-1500 mandrel upender with soft-touch controls

- Results:

- Damage claims reduced by 85%

- Throughput increased by 30%

- ROI achieved in 14 months

2. How Do You Calculate ROI When Investing in Coil Upender Automation?

Leading Paragraph:

Michael, as a plant manager, you're constantly pressured to justify equipment investments. I've helped numerous Mexican factories calculate the true ROI of coil upenders, and the numbers often surprise even experienced managers. Let me show you the concrete financial benefits beyond just labor savings.

Snippet Paragraph:

A typical coil upender ROI calculation should include: labor cost reduction (saving 3-4 workers per shift), productivity gains (30-50% faster processing), damage reduction (60-80% fewer claims), and safety cost savings. Based on SHJLPACK data from Mexican installations, most plants achieve full ROI within 12-24 months, with ongoing annual savings of $80,000-$150,000 depending on operation scale.

Dive Deeper Content:

Step-by-Step ROI Calculation for Mexican Plants

Step 1: Current Manual Handling Costs

Most Mexican plants use 4 workers for manual coil flipping across two shifts. Let's calculate your current expenses:

- Labor: 4 workers × $2,000/month × 12 months = $96,000/year

- Benefits & Insurance: Additional 30% = $28,800/year

- Product Damage: Average 3% of coil value = $45,000/year (based on $1.5M annual coil processing)

- Safety Incidents: Average $15,000/year in direct costs

- Total Current Cost: $184,800/year

Step 2: Automated Upender Investment

A SHJLPACK SU-2000 saddle upender represents a typical investment:

- Equipment Cost: $65,000

- Installation & Training: $10,000

- Annual Maintenance: $3,000

- Operator Cost: 1 worker × $2,500/month × 12 = $30,000/year

Step 3: Savings Calculation

- Labor Reduction: $96,000 - $30,000 = $66,000/year

- Damage Reduction: 80% of $45,000 = $36,000/year

- Safety Cost Elimination: $15,000/year

- Productivity Gain: 40% faster processing = $52,000/year in additional throughput

- Total Annual Savings: $169,000

ROI Period: ($65,000 + $10,000) ÷ $169,000 = 0.44 years (≈ 5.3 months)

Hidden Cost Factors Many Plants Miss

According to Randal Liu's experience with Mexican manufacturers, most ROI calculations underestimate these critical factors:

Uptime Impact:

Manual handling causes 15-20% unplanned downtime due to fatigue and safety protocols. Automated upenders maintain consistent speed regardless of shift duration.

Quality Consistency:

Automated rotation eliminates human error in positioning, reducing subsequent packing and handling issues by 25-35%.

Scalability Value:

As your Mexican plant grows, automated upenders can integrate with full steel coil packing line systems, avoiding future reinvestment.

3. What Safety Features Are Critical for Mexican Industrial Standards?

Leading Paragraph:

Safety isn't just compliance—it's profitability. In Mexican manufacturing, workplace injuries can shut down operations for weeks and skyrocket insurance premiums. The right upender safety features protect your team while ensuring continuous production that managers like Michael depend on.

Snippet Paragraph:

Critical safety features for Mexican coil upenders include: dual emergency stop systems, overload protection sensors, anti-slip rotation platforms, guarded pinch points, and NOM-compliant control panels. SHJLPACK upenders incorporate all these features plus optional laser safety curtains, reducing typical manual handling injuries by 95% according to installation data from Mexican steel plants.

Dive Deeper Content:

Essential Safety Systems Breakdown

Mechanical Safety Systems:

- Dual Emergency Stops: Redundant buttons at operator height and floor level

- Overload Protection: Automatic shutdown at 110% rated capacity

- Anti-Drop Hydraulic Valves: Prevent free-fall during power loss

- Physical Guards: Full enclosure of rotating components meeting Mexican NOM standards

Electronic Safety Systems:

- Light Curtains: Laser detection stops operation if workers enter danger zones

- Position Sensors: Ensure proper coil placement before rotation

- Speed Monitoring: Automatic slowdown for unstable loads

- Remote Control Operation: Allows positioning from safe distances

Compliance with Mexican Regulations

Mexican NOM standards require specific safety implementations that many imported upenders lack. SHJLPACK designs specifically address these requirements:

NOM-001-STPS-2008: Electrical safety compliance through isolated control panels

NOM-004-STPS-1999: Machine guarding and emergency stop accessibility

NOM-026-STPS-2008: Noise level controls below 85 dB

NOM-029-STPS-2011: Proper illumination in work areas

Safety ROI: Beyond Accident Prevention

While preventing injuries is paramount, safety features deliver measurable financial benefits:

Insurance Premium Reduction:

Mexican plants with certified safety systems typically see 15-25% lower insurance costs—saving $7,000-$15,000 annually for medium operations.

Reduced Downtime:

Safety incidents cause average 3-5 days production halt. At $5,000 daily output value, this represents $15,000-$25,000 per incident.

Workforce Stability:

Safe environments reduce employee turnover. Replacing trained workers costs $3,000-$5,000 each in recruitment and training.

4. How to Choose Between Chinese Brands: SHJLPACK, 风鼎, or 无锡步惠?

Leading Paragraph:

Facing multiple Chinese equipment suppliers can be overwhelming. Each claims to be the best, but as someone who's worked on both factory floors and management offices, I've seen the real differences that matter for Mexican operations. Let me simplify your supplier decision with transparent comparisons.

Snippet Paragraph:

For Mexican steel plants, SHJLPACK offers the best value with localized Spanish support and Mexico-specific customization, while 风鼎 (Fhopepack) provides reliable mid-range options, and 无锡步惠 suits budget-conscious smaller operations. According to installation data, SHJLPACK upenders demonstrate 30% higher uptime in Mexican conditions due to tropicalized components and voltage stabilization systems designed for local power fluctuations.

Dive Deeper Content:

Detailed Brand Comparison for Mexican Market

SHJLPACK Advantages:

✓ Localized Support: Spanish-speaking technicians and Mexico-based spare parts

✓ Climate Adaptation: Special corrosion protection for coastal Mexican plants

✓ Power Compatibility: Built for Mexican voltage standards (127V/220V, 60Hz)

✓ Customization: Modify upender dimensions for specific Mexican factory layouts

✓ Training: On-site instruction in Spanish for your maintenance team

风鼎 (Fhopepack) Strengths:

✓ Good basic reliability for standard applications

✓ Competitive pricing for plants with tight budgets

✓ Adequate performance in controlled environments

✓ Reasonable delivery times (8-10 weeks)

无锡步惠 Positioning:

✓ Entry-level pricing attractive for small operations

✓ Basic functionality meets minimum requirements

✓ Suitable for light-duty applications only

✓ Limited customization capabilities

Technical Specification Comparison

| Feature | SHJLPACK SU-2000 | 风鼎 FD-1800 | 无锡步惠 WX-1500 |

|---|---|---|---|

| Max Capacity | 20 tons | 18 tons | 15 tons |

| Construction | Reinforced steel frame | Standard steel | Light steel |

| Hydraulic System | German components | Chinese premium | Chinese standard |

| Control Panel | SIEMENS (NOM compliant) | Chinese brand | Basic controls |

| Warranty | 2 years + local support | 1 year limited | 6 months |

| Delivery to Mexico | 6-8 weeks | 8-10 weeks | 10-12 weeks |

| Spare Parts Availability | Mexico warehouse | China shipment | China shipment |

| Price Range | $60,000-75,000 | $45,000-55,000 | $35,000-42,000 |

Decision Framework for Mexican Plant Managers

Choose SHJLPACK if:

- You operate in coastal areas with high humidity

- Your plant experiences power fluctuations

- You need Spanish technical documentation

- You prioritize uptime over initial cost savings

- You plan to expand to full automation later

Consider 风鼎 if:

- Your budget is constrained but you need reliability

- You have stable indoor operating conditions

- You have technical staff comfortable with English documentation

- Your operation is standard without special requirements

无锡步惠 only for:

- Very tight budget situations

- Light-duty, intermittent use

- Operations with strong in-house maintenance capabilities

- Temporary or backup equipment needs

Conclusion

Selecting the right coil upender significantly impacts your Mexican plant's efficiency, safety, and profitability. For most operations, saddle upenders from experienced suppliers like SHJLPACK deliver the optimal balance of performance and durability. Remember to integrate your upender choice with your overall steel coil packing line strategy for maximum benefits.

FAQ Section

Frequently Asked Questions

Q: What maintenance do coil upenders require in Mexican industrial environments?

A: Monthly visual inspections, quarterly hydraulic system checks, and annual comprehensive maintenance. In Mexican coastal areas, additional corrosion protection is recommended. SHJLPACK upenders require 30% less maintenance than standard models due to tropicalized components.

Q: How long does installation typically take in Mexican manufacturing plants?

A: Most upender installations require 3-5 days with proper site preparation. SHJLPACK provides pre-installation checklists to ensure your Mexican plant is ready, minimizing production disruption. Complex integrations with existing packing lines may extend to 7-10 days.

Q: Can coil upenders handle different coil sizes in the same production shift?

A: Yes, modern upenders like SHJLPACK models feature adjustable arms or programmable settings for different coil diameters. Changeover typically takes 5-15 minutes depending on the size variation and upender type. Automatic adjustment systems are available for frequent size changes.

Q: What power requirements do coil upenders have for Mexican factories?

A: Most industrial upenders require 220V/380V, 3-phase power, 50-60Hz. Power consumption ranges from 7.5kW for basic models to 22kW for heavy-duty systems. SHJLPACK upenders include voltage stabilization for Mexico's common power fluctuations.

Q: How do I calculate the right upender capacity for my Mexican operation?

A: Consider your heaviest typical coil plus 20% safety margin. For example, if your maximum coil is 12 tons, choose a 15-ton capacity upender. Also factor in future production increases—investing in slightly higher capacity often provides better long-term value.