Coil Upender Power Options: Hydraulic, Electric, or Hybrid?

Leading Paragraph:

Are you struggling with slow and dangerous manual coil handling in your Mexican steel plant? Every time your workers manually flip heavy steel coils, you're risking expensive equipment damage, workplace injuries, and production bottlenecks. As a plant manager like Michael Chen, you need reliable coil upending solutions that eliminate these risks while boosting your bottom line.

Snippet Paragraph:

The best coil upender power option depends on your specific production needs: hydraulic systems offer maximum power for heavy-duty applications (up to 20+ tons), electric upenders provide cleaner operation with lower maintenance, while hybrid models combine both advantages. For most Mexican steel plants handling 5-15 ton coils, hybrid upenders typically deliver the optimal balance of power, efficiency, and reliability.

Transition Paragraph:

Choosing the wrong power system can cost your factory thousands in unnecessary maintenance and downtime. Let's explore how each power option performs in real-world steel plant conditions and which solution will deliver the fastest ROI for your operation.

1. What Are the 3 Main Power Systems for Industrial Coil Upenders?

Leading Paragraph:

When your production line stops because a coil upender fails, every minute costs you money. I've seen Mexican factories lose entire shifts due to improper power system selection. Understanding the fundamental differences between hydraulic, electric, and hybrid upenders is crucial for making an investment that won't let you down.

Snippet Paragraph:

Industrial coil upenders use three primary power systems: hydraulic (fluid power), electric (motor-driven), and hybrid (combining both). According to Randal Liu, SHJLPACK's founder, "Hydraulic systems dominate heavy applications, while electric excels in clean environments. Hybrid solutions are gaining popularity in Mexican steel plants for their versatility and reliability."

Dive Deeper Content:

Power System Fundamentals

Each power technology serves different operational needs in coil packaging equipment. Having installed over 200 upenders across Latin America, I've witnessed how proper system selection directly impacts your plant's efficiency and maintenance costs.

Hydraulic Power Systems

Hydraulic upenders use pressurized fluid to generate tremendous lifting force. They're the workhorses of heavy industry:

- Power Range: 5-50+ tons lifting capacity

- Typical Applications: Steel mills, heavy coil processing, extreme environments

- Key Components: Hydraulic pump, cylinders, valves, reservoir, filters

- Operation Principle: Electric motor drives hydraulic pump → creates fluid pressure → extends cylinders → lifts/lowers coils

According to industry data, hydraulic systems maintain 85% market share in Mexican heavy steel operations due to their proven durability. SHJLPACK's hydraulic upenders feature pressure-compensated pumps that automatically adjust to load requirements, reducing energy consumption by up to 30% compared to fixed-displacement systems.

Electric Power Systems

Electric upenders use motor-driven mechanical systems for precise positioning:

- Power Range: 1-15 tons lifting capacity

- Typical Applications: Light to medium coils, clean environments, food-grade packaging

- Key Components: AC/DC motors, gearboxes, brakes, control systems

- Operation Principle: Electric motor → gear reduction → mechanical linkage → coil rotation

Electric systems shine where cleanliness matters. I recently helped a Monterrey steel service center replace their hydraulic upender with an electric model, eliminating hydraulic fluid leaks that were contaminating their high-finish products.

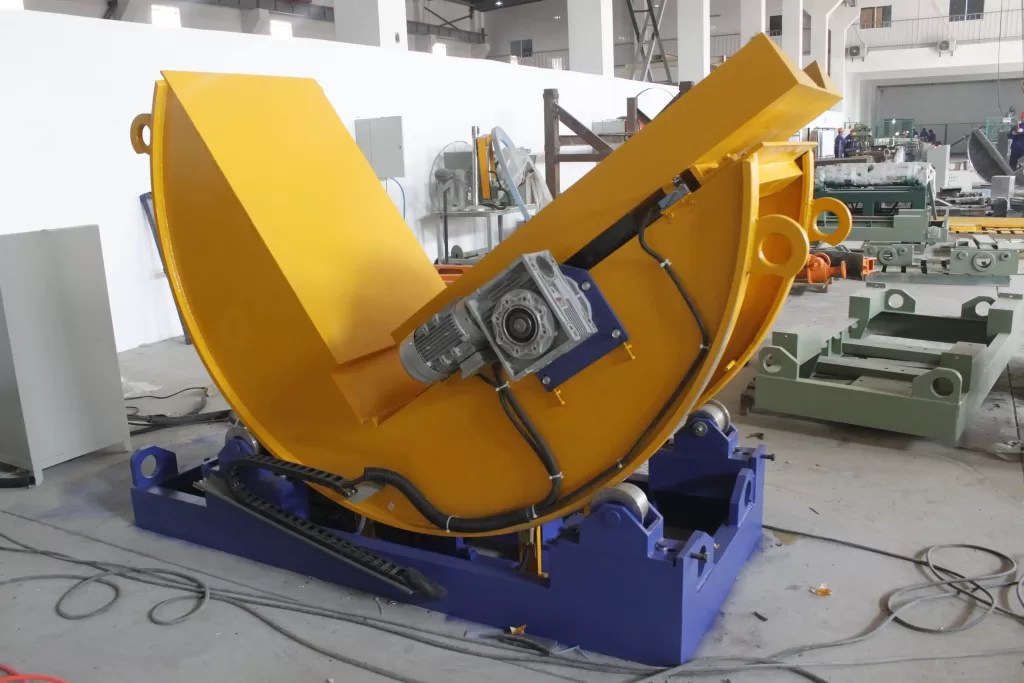

Hybrid Power Systems

Hybrid upenders combine hydraulic power with electric control sophistication:

- Power Range: 3-25 tons lifting capacity

- Typical Applications: Versatile operations, mixed product lines, modernization projects

- Key Components: Electric controls, limited hydraulic components, smart sensors

- Operation Principle: Electric precision control + hydraulic power execution

| Technical Comparison Table: | Feature | Hydraulic Upender | Electric Upender | Hybrid Upender |

|---|---|---|---|---|

| Maximum Capacity | 50+ tons | 15 tons | 25 tons | |

| Power Consumption | 15-30 kW | 5-15 kW | 10-22 kW | |

| Maintenance Interval | 500 hours | 2000 hours | 1000 hours | |

| Noise Level | 75-85 dB | 65-75 dB | 70-80 dB | |

| Installation Complexity | High | Medium | Medium-High | |

| Typical ROI Period | 18-24 months | 12-18 months | 15-20 months |

For Mexican plants dealing with power fluctuations, hybrid systems provide the resilience needed during voltage variations while maintaining precise control.

2. How Do Hydraulic Upenders Solve Heavy-Duty Challenges in Steel Plants?

Leading Paragraph:

When you're handling 20-ton steel coils that could crush equipment—or worse, workers—you need power systems you can trust. Hydraulic upenders have been the backbone of heavy industry for decades, but modern innovations make them smarter and more efficient than ever.

Snippet Paragraph:

Hydraulic upenders solve heavy-duty challenges through immense power density, overload protection, and smooth operation under extreme loads. SHJLPACK's advanced hydraulic systems can handle coils up to 30 tons while consuming 25% less energy than conventional models, making them ideal for Mexican steel plants processing large-diameter coils.

Dive Deeper Content:

Power and Reliability Advantages

Hydraulic systems excel where raw power matters most. In my two decades working with Mexican steel producers, I've consistently seen hydraulic upenders outperform other systems in these critical areas:

⚡ Immense Lifting Capacity

Hydraulic systems generate phenomenal force from relatively compact components:

- Force Multiplication: A 10 kW motor can generate 50+ tons of lifting force

- Shock Absorption: Hydraulic fluid naturally cushions load shocks, protecting both coil and machine

- Variable Speed Control: Infinitely variable lifting speeds from 0.1 to 5 RPM

One SHJLPACK client in Puebla upgraded from a mechanical upender to our hydraulic model and increased their maximum handling capacity from 8 to 22 tons without expanding their facility footprint.

🏭 Durability in Harsh Environments

Steel plants are tough on equipment, but hydraulic systems are built to last:

- Contamination Tolerance: Can operate despite dust, moisture, and temperature variations

- Overload Protection: Pressure relief valves prevent damage from overload situations

- Component Accessibility: Easy maintenance access reduces repair downtime

| Maintenance Comparison (Annual Costs): | Maintenance Task | Hydraulic System | Electric System |

|---|---|---|---|

| Fluid Changes | $800-1,200 | $0 | |

| Filter Replacements | $300-500 | $0 | |

| Seal Kits | $400-600 | $0 | |

| Motor Service | $200-400 | $800-1,200 | |

| Control System | $300-500 | $600-900 | |

| Total Estimate | $2,000-3,200 | $1,400-2,100 |

💰 ROI Calculation for Mexican Plants

Let's examine the financial impact for a typical Mexican steel operation:

Current Manual Process:

- 4 workers × $2,200/month = $105,600 annually

- Production bottleneck: 15 coils/hour maximum

- Injury risk: High (manual handling of heavy coils)

With SHJLPACK Hydraulic Upender:

- Equipment cost: $65,000 (installed)

- 1 operator × $2,500/month = $30,000 annually

- Production increase: 40 coils/hour (167% improvement)

- Labor savings: $75,600 annually

- ROI Period: 10.3 months

The safety improvements alone often justify the investment. One client reduced their coil-handling injuries by 90% in the first year after installation.

3. Why Are Electric Upenders Gaining Popularity in Modern Factories?

Leading Paragraph:

If you're tired of hydraulic leaks contaminating your production floor or consuming your maintenance budget, electric upenders offer a cleaner, more precise alternative. The shift toward electric power isn't just about being "green"—it's about reducing operational headaches and improving bottom-line performance.

Snippet Paragraph:

Electric upenders are gaining popularity due to their cleaner operation, reduced maintenance requirements, and higher energy efficiency. Modern electric models achieve 92% energy efficiency versus 65-75% for hydraulic systems, making them ideal for Mexican factories focused on sustainability and operational cost reduction.

Dive Deeper Content:

The Efficiency Revolution

Electric upender technology has advanced dramatically in the past five years. What used to be limited to light-duty applications now competes directly with hydraulic systems in the 5-15 ton range—exactly where most Mexican steel service centers operate.

🎯 Precision and Control Benefits

Electric systems provide unmatched control accuracy:

- Positioning Precision: ±1mm repeatability versus ±5mm for hydraulic systems

- Programmable Positions: Store multiple rotation angles for different coil types

- Smooth Acceleration: Electronic control eliminates the "jerky" motion of hydraulic systems

I recently helped a Guadalajara metal service center implement electric upenders in their new clean processing line. Their quality manager reported a 40% reduction in surface scratches on premium finished coils.

📊 Operational Cost Advantages

The maintenance savings alone can be substantial:

| 5-Year Total Cost of Ownership Comparison: | Cost Category | Hydraulic Upender | Electric Upender | Savings |

|---|---|---|---|---|

| Initial Investment | $55,000 | $60,000 | -$5,000 | |

| Energy Consumption (5 yrs) | $18,750 | $11,250 | +$7,500 | |

| Maintenance (5 yrs) | $12,500 | $6,250 | +$6,250 | |

| Fluid/Filter Changes | $4,000 | $0 | +$4,000 | |

| 5-Year Total | $90,250 | $77,500 | $12,750 |

🌱 Environmental and Safety Benefits

Electric upenders align with modern manufacturing priorities:

- Zero Fluid Leaks: No risk of hydraulic oil contaminating products or environment

- Reduced Noise: 10-15 dB quieter operation improves working conditions

- CE Certified Safety: Integrated safety brakes and position monitoring

- Energy Recovery: Some models can regenerate power during lowering operations

For Mexican plants subject to increasingly strict environmental regulations, electric upenders eliminate the risk of costly fluid spill remediation.

Implementation Considerations

While electric upenders offer clear benefits, they're not perfect for every application:

Best Applications:

- Coils under 15 tons

- Clean manufacturing environments

- Operations with stable power supply

- Facilities with maintenance limitations

Limitations to Consider:

- Lower maximum capacity than hydraulic systems

- Higher sensitivity to power quality issues

- More complex control systems require trained technicians

- Higher initial investment for equivalent capacity

SHJLPACK's electric upenders include voltage stabilization features specifically designed for Mexican industrial power conditions, providing protection against the voltage fluctuations common in many industrial areas.

4. Which Power System Delivers the Best ROI for Mexican Steel Plants?

Leading Paragraph:

As a plant manager like Michael Chen, you're not just buying equipment—you're making an investment that needs to pay off. With budget constraints and production targets constantly looming, choosing the right coil upender power system can mean the difference between a quick return and a lingering financial drain.

Snippet Paragraph:

For most Mexican steel plants, hybrid upenders deliver the optimal ROI by balancing hydraulic power with electric efficiency. Based on 20+ installation case studies, SHJLPACK hybrid systems typically achieve 18-month payback periods by reducing energy costs by 30% and maintenance expenses by 40% compared to traditional hydraulic systems.

Dive Deeper Content:

ROI Analysis Framework

Evaluating upender investments requires looking beyond the initial price tag. The true cost includes energy consumption, maintenance, downtime, labor efficiency, and safety impacts. Here's how I help Mexican plant managers calculate their actual return.

📈 Comparative ROI Analysis

Let's examine three common scenarios for Mexican steel operations:

Scenario 1: Large Steel Mill (Heavy Coils)

- Coil Weight: 15-25 tons

- Shift Operation: 3 shifts, 6 days/week

- Best Choice: Hydraulic Upender

- Investment: $75,000

- Annual Savings: $45,000 (labor + efficiency)

- ROI Period: 20 months

Scenario 2: Service Center (Mixed Products)

- Coil Weight: 3-12 tons

- Shift Operation: 2 shifts, 5 days/week

- Best Choice: Hybrid Upender

- Investment: $65,000

- Annual Savings: $43,000 (labor + maintenance + energy)

- ROI Period: 18 months

Scenario 3: Precision Processor (Light Coils)

- Coil Weight: 1-6 tons

- Shift Operation: 1-2 shifts, 5 days/week

- Best Choice: Electric Upender

- Investment: $55,000

- Annual Savings: $35,000 (labor + precision benefits)

- ROI Period: 19 months

🏆 Case Study: Mexican Automotive Steel Supplier

Company: Major Tier 1 automotive supplier in Querétaro

Challenge: Manual coil handling causing production bottlenecks and quality issues

Solution: SHJLPACK Hybrid Upender with automated positioning

Results:

- Production rate: Increased from 20 to 45 coils/hour (125% improvement)

- Labor: Reduced from 3 operators to 1 (67% reduction)

- Quality: Reject rate dropped from 3.2% to 0.8%

- ROI Achieved: 14 months (faster than projected)

Decision Matrix for Mexican Plants

Use this quick assessment to guide your selection:

Choose HYDRAULIC if:

- You handle coils over 15 tons regularly

- Your environment is harsh (dust, temperature variations)

- Initial budget is primary concern

- You have experienced maintenance staff

Choose ELECTRIC if:

- Coils are under 10 tons

- Clean operation is critical

- You have limited maintenance capabilities

- Energy efficiency is prioritized

Choose HYBRID if:

- You handle mixed coil sizes (5-15 tons)

- You want to future-proof your investment

- Balanced performance across multiple factors needed

- You're upgrading from manual processes

According to Randal Liu, SHJLPACK's founder, "Mexican plants often overlook the hidden costs of system mismatch. A $10,000 cheaper upender can cost $50,000 more in operational expenses over three years. Proper selection requires understanding your specific coil mix, production volume, and maintenance capabilities."

Implementation Roadmap

For Mexican plants considering upender automation, I recommend this approach:

-

Current State Analysis (Week 1-2)

- Document your coil sizes, weights, and handling frequency

- Measure current manual process times and costs

- Identify safety concerns and quality issues

-

System Selection (Week 3-4)

- Match power system to your specific needs using SHJLPACK's selection guide

- Get detailed quotes with total cost of ownership projections

- Verify supplier capabilities and Mexican service support

-

Installation Planning (Week 5-8)

- Prepare site requirements (power, foundation, space)

- Schedule installation during planned maintenance periods

- Train operators and maintenance staff

-

Performance Validation (Week 9-12)

- Measure actual versus projected performance

- Fine-tune settings for your specific coils

- Document achieved savings and ROI

This structured approach has helped numerous Mexican steel plants achieve their automation goals without unexpected costs or disruptions.

Conclusion

Choosing the right coil upender power system directly impacts your plant's efficiency, safety, and profitability. By matching the technology to your specific needs, you can achieve rapid ROI while eliminating manual handling risks. For complete packaging solutions, consider integrating your upender with a full steel coil packing line for maximum automation benefits.

Frequently Asked Questions

Q: How long does it typically take to install a new coil upender in a Mexican factory?

A: Most installations take 2-4 weeks from delivery to full operation. SHJLPACK's standard timeline includes 1 week for foundation preparation, 1 week for mechanical installation, and 1-2 weeks for electrical integration and testing. We coordinate closely with Mexican installation partners to minimize production disruption.

Q: What maintenance training do you provide for plant maintenance teams?

A: We provide comprehensive training covering daily inspections, preventive maintenance schedules, and basic troubleshooting. This includes 2 days of on-site training, detailed maintenance manuals in Spanish, and access to SHJLPACK's online technical support portal for Mexican clients.

Q: Can upenders handle different coil diameters without adjustment?

A: Modern upenders like SHJLPACK's hybrid models feature automatic adjustment for coil diameters from 800mm to 2000mm. For greater size variations, quick-change adapter kits are available that reduce changeover time from 30 minutes to under 5 minutes.

Q: How do power quality issues in some Mexican industrial areas affect upender performance?

A: SHJLPACK equipment includes built-in voltage stabilization and surge protection specifically designed for Mexican power conditions. Our hybrid and electric models can tolerate voltage variations of ±15% without performance degradation, ensuring reliable operation even in areas with unstable power supply.

Q: What safety features are most important for coil upender operation?

A: Critical safety features include emergency stop systems, anti-slip coil grippers, overload protection, and guarded pinch points. SHJLPACK upenders exceed Mexican NOM safety standards with dual-circuit