Upender Machine Reliability: What Delivers 99.5% Uptime in Mill Conditions?

Your steel mill is a complex system. Every single piece of equipment has to work perfectly. But one machine, the upender, can become a major bottleneck if it fails. An unexpected breakdown stops your production line cold. This means lost output, delayed shipments, and mounting costs. You know the pressure of keeping everything running smoothly, and a single unreliable machine can jeopardize your entire operation's efficiency and profitability.

Achieving 99.5% uptime for an upender in demanding mill conditions comes from a combination of three key factors: an over-engineered mechanical structure built for harsh environments, a high-quality, redundant hydraulic and electrical system using trusted components, and a strategic approach to maintenance supported by smart, data-driven features. It is not just about the machine, but the philosophy behind its design and support.

I've spent my entire career in and around packing machine factories, first as an engineer and now as a factory owner. I've seen firsthand what separates a machine that lasts from one that causes constant headaches. For a leader like Javier Morales, who manages a massive steel operation and scrutinizes every investment, uptime isn't just a number—it's the foundation of profitability. You understand that the true cost of a machine isn't its purchase price, but the cost of its downtime. So, let's break down exactly what goes into building an upender that you can truly rely on, day in and day out.

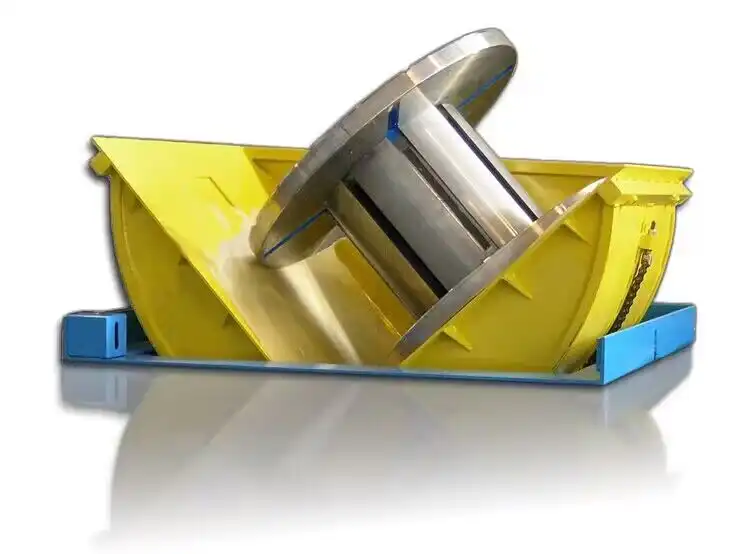

How Can Robust Mechanical Design Withstand Harsh Mill Environments?

The floor of a steel mill is one of the toughest places for any machine to operate. You have constant vibrations, heavy dust, extreme temperature swings, and the relentless impact of moving massive steel coils. Standard-issue equipment simply can't survive. This leads to frequent breakdowns, where you're forced into unplanned maintenance, replacing worn-out bearings or fixing cracked welds. It's a frustrating cycle that eats into your production schedule and budget.

A robust mechanical design withstands harsh mill environments by using superior materials and over-engineered components. This includes a heavy-duty, stress-relieved steel frame, top-tier bearings and drivetrains designed for high shock loads, and advanced surface treatments that protect against corrosion and abrasion. The goal is to build a machine that anticipates the stress, rather than just reacting to it.

%[A large, custom-built upender machine being worked on in the SHJLPACK factory.](https://www.fhopepack.com/blog/wp-content/uploads/2023/07/our-work-upender-768x763.webp "Custom-built Upender Machine")

Let's dive deeper into what this actually means. It’s not about just making things "heavy." It's about smart, intentional design based on years of seeing what fails in the real world. I remember visiting a client's plant in Mexico. Their existing upender, from another supplier, was a constant source of trouble. The main frame had developed stress fractures near the main pivot point. The reason was clear: the design didn't properly distribute the immense forces generated when tilting a 30-ton coil. It was a classic case of under-engineering. We didn't just propose a replacement; we showed them the finite element analysis (FEA) of our proposed design, highlighting how we reinforced those exact high-stress areas. That's the level of detail that matters.

Structural Integrity: The Foundation of Reliability

The frame is the backbone of the upender. A weak frame will flex under load, causing misalignment in all other components, which leads to premature wear and failure.

- Material Selection: We don't use standard structural steel. We use high-tensile steel, like Q345B or its equivalent, which has better strength and fatigue resistance.

- Welding and Stress Relief: All welding is performed by certified welders following strict procedures. More importantly, after the frame is fully welded, the entire structure undergoes a heat treatment process called "stress relieving." This process heats the frame to a specific temperature and then slowly cools it, relaxing the internal stresses created during welding. This single step dramatically reduces the risk of cracks forming over the machine's lifetime.

Drivetrain and Bearings: The Heart of the Movement

These are the components that do the actual work. In a mill, they are subjected to incredible shock loads.

- Drive System: For the tilting motion, a powerful motor combined with a high-ratio, heavy-duty gearbox is essential. We select gearboxes with a service factor of 2.0 or higher. This means it's rated to handle twice the nominal load, providing a huge safety margin against the shock of starting and stopping a heavy coil.

- Bearing Selection: Standard bearings will be destroyed quickly. We use oversized spherical roller bearings from premium brands like SKF or FAG. These bearings are self-aligning, so they can accommodate slight frame flex without damage, and they are designed specifically for high radial and axial loads.

Surface Protection: The Shield Against the Elements

A steel mill environment is highly corrosive. Steel dust, moisture, and chemical fumes will attack any unprotected surface.

| Feature | Standard Approach | Mill-Duty Approach (SHJLPACK) | Benefit for Your Mill |

|---|---|---|---|

| Frame Material | Standard Carbon Steel (e.g., Q235) | High-Tensile Steel (e.g., Q345B) with Stress Relief Treatment | Prevents frame cracking and deformation; extends structural life. |

| Main Bearings | Standard Deep Groove Ball Bearings | Oversized Spherical Roller Bearings (SKF, FAG) | Absorbs shock loads and misalignment; reduces bearing failure. |

| Surface Prep | Simple Sanding or Wire Brushing | SA 2.5 Sandblasting | Creates an ideal surface for paint adhesion; prevents rust creep. |

| Coating System | Single-layer industrial paint | Three-layer Marine-Grade Epoxy System (Primer, Intermediate, Top Coat) | Provides long-term protection against corrosion and abrasion. |

This level of mechanical engineering is not an optional extra; it is the absolute minimum requirement for achieving reliability in a place as demanding as your steel mill.

What Role Does the Hydraulic and Electrical System Play in Achieving Peak Uptime?

You've experienced it before. A perfectly good mechanical structure is brought to its knees by a failed hydraulic hose, a faulty sensor, or a problematic PLC. In a high-production environment, these "small" failures are anything but. They trigger emergency stops, require specialist technicians to diagnose, and can be frustratingly difficult to trace. The electrical and hydraulic systems are the machine's brain and muscles. If they are not dependable, the machine's strength is useless.

The hydraulic and electrical systems are critical for peak uptime; their reliability hinges on using high-quality, globally recognized components, designing for system redundancy, and ensuring ease of maintenance. A well-designed system uses brands like Siemens and Schneider and incorporates features like dual filtration and intelligent valve blocks to prevent common failure points and simplify troubleshooting.

I learned this lesson the hard way early in my career. We built a machine for a client with a hydraulic power pack that used components from a lesser-known supplier to save on costs. The machine worked fine during testing. But three months into operation at the client's site, a valve failed. Getting a replacement took over a week because the part wasn't locally available. That one week of downtime cost my client far more than the initial savings on the component. From that day on, I made it a non-negotiable rule: we only use components from major, global brands that our clients can trust and source easily. For a CEO like Javier, who thinks about long-term operational stability, this philosophy is key. It's not about the brand name for show; it's about global parts availability and proven reliability.

The Hydraulic Power Unit: Controlled Force

The hydraulic system provides the immense force needed to tilt multi-ton coils smoothly and safely. Reliability here is about both power and control.

- Component Quality: The heart of the system is the power pack. We use pumps from brands like Rexroth or Parker, known for their durability. All valves are housed in a central manifold block. This minimizes potential leak points from extensive piping and hoses. We use high-pressure hoses with an extra layer of abrasion-resistant coating to protect against accidental damage.

- Filtration and Cooling: Hydraulic oil contamination is a leading cause of failure. Our systems include dual-stage filtration—a suction filter to protect the pump and a high-pressure return line filter to catch wear particles. We also include an air- or water-cooled heat exchanger. This keeps the oil at an optimal temperature, extending its life and preventing seals and valves from failing due to overheating, a common issue in hot mill environments.

The Electrical and Control System: The Brain of the Operation

The control system dictates every movement. Its reliability is paramount for safety and consistent performance.

- Centralized Control Cabinet: All electrical components are housed in an IP55-rated or higher cabinet. This protects them from the dust and moisture prevalent in a mill. Inside, the layout is clean and all wires are clearly labeled. This seems basic, but during a breakdown at 2 a.m., clear labeling can turn a multi-hour troubleshooting job into a 15-minute fix.

- Premium Components: We standardize on globally recognized brands for all critical components. This means a Siemens or Allen-Bradley PLC, Schneider Electric contactors and circuit breakers, and Sick or Banner sensors. This ensures that if a component ever does fail, you can likely find a replacement from a local distributor anywhere in the world, including Mexico.

- Soft Start and VFDs: We use soft starters or Variable Frequency Drives (VFDs) on all large motors. This reduces the immense electrical and mechanical shock during startup, extending the life of the motor, gearbox, and couplings. A VFD also allows for precise speed control, ensuring smooth acceleration and deceleration, which is gentler on the coil and the machine.

| System Element | Standard Implementation | High-Uptime Implementation (SHJLPACK) | Impact on Reliability |

|---|---|---|---|

| PLC/Controls | Proprietary or lesser-known brand | Siemens, Allen-Bradley, or Mitsubishi | Global support, easy integration, reliable performance. |

| Hydraulic Valves | Individual valves with extensive piping | Integrated manifold valve block | Drastically reduces potential leak points, simplifies maintenance. |

| Motor Control | Direct-on-line starter | Soft Starter or Variable Frequency Drive (VFD) | Reduces mechanical shock, lowers energy use, enables fine control. |

| System Cooling | Relies on ambient air | Dedicated Air/Oil or Water/Oil Heat Exchanger | Prevents oil degradation and component failure from overheating. |

These aren't just features. They are deliberate engineering choices that directly combat the most common reasons for downtime in hydraulic and electrical systems.

How Do Smart Features and Predictive Maintenance Push Uptime Beyond 99%?

Even with the best mechanical and electrical design, you are still operating in a reactive mode. You wait for something to break before you fix it. This is the old way of thinking. In today's competitive steel market, you need to be proactive. You need to know there's a problem developing before it causes a shutdown. This is a core part of your goal to increase equipment effective time to 95% and implement a digital transformation. Smart features are no longer a luxury; they are a necessity for achieving elite levels of operational excellence.

Smart features and predictive maintenance push uptime beyond 99% by transforming unscheduled downtime into scheduled maintenance. This is done by embedding IoT sensors to monitor key parameters like vibration, temperature, and hydraulic pressure, and then using that data to predict failures before they happen, allowing you to plan repairs during scheduled shutdowns.

I've been on a journey from a hands-on engineer to a business owner focused on data. I see the same shift happening with our most forward-thinking clients. A few years ago, we installed an upender for a large steel processor. Six months in, we got an automated alert from their system. The vibration sensor on the main gearbox bearing was showing a tiny, but steady, increase in its signature. To the naked eye, the machine was running perfectly. But the data told a different story. We advised them to inspect the bearing during their next planned maintenance window. They found the bearing had a microscopic flaw and was in the very early stages of failing. They replaced it in two hours during a planned stop. Had they waited for it to fail catastrophically, it would have taken the gearbox with it, leading to a week of downtime and tens of thousands of dollars in damage. That is the power of predictive maintenance.

The Foundation: Data Collection with IoT

You can't manage what you don't measure. The first step is to equip the upender with a suite of smart sensors.

- Vibration Sensors: Placed on the motor, gearbox, and main pivot bearings. These are the most critical indicators of mechanical health. They can detect bearing wear, gear tooth damage, and misalignment long before they become audible or visible.

- Temperature Sensors: Monitor the hydraulic oil, motor casings, and main bearings. A gradual increase in temperature is a clear sign of a problem, such as oil degradation, excessive friction, or a failing component.

- Hydraulic Pressure and Flow Sensors: These provide a real-time view of the hydraulic system's health. A drop in pressure or an erratic flow rate can indicate an internal leak, a weakening pump, or a clogged filter.

- Cycle Counter and Load Cells: Track the total number of cycles the machine has performed and the weight of each coil. This data is crucial for scheduling lifecycle-based maintenance (e.g., "replace bearing after 500,000 cycles").

The Intelligence: Data Analysis and MES Integration

Collecting data is only half the battle. The real value comes from turning that data into actionable insights.

- On-board HMI: The machine's Human-Machine Interface (HMI) displays all this data in a clear, graphical format. It will show trend lines for key parameters and trigger alarms if any measurement goes outside of its safe operating window. This gives your operators and maintenance staff immediate visibility.

- Integration with Plant MES: For a truly digital operation like the one you envision, the upender must communicate with your plant's Manufacturing Execution System (MES). Our control systems are designed to do this seamlessly using standard protocols like OPC-UA or Profinet. This allows you to monitor the upender's health from a central control room, correlate its performance with upstream and downstream processes, and automatically generate maintenance work orders in your system.

The Goal: From Reactive to Predictive

This approach fundamentally changes how you manage maintenance.

| Maintenance Strategy | How It Works | Impact on Uptime |

|---|---|---|

| Reactive | "If it ain't broke, don't fix it." Wait for a failure to occur, then repair. | Lowest uptime. Leads to catastrophic failures and long, unplanned downtime. |

| Preventive | "Fix it before it breaks." Replace parts on a fixed time or cycle schedule. | Better uptime, but can be wasteful. You might replace perfectly good parts. |

| Predictive | "Fix it when it needs it." Use real-time data to predict when a part will fail. | Highest possible uptime. Maintenance is targeted, efficient, and scheduled. |

By adopting a predictive maintenance strategy for key equipment like your upender, you directly address your goals of increasing uptime, reducing costs, and driving a successful digital transformation across your mill.

Why is a Partnership Approach More Critical Than Just Buying a Machine?

You can buy a well-built machine from several manufacturers. You can find equipment with good components and even some smart features. But your goals go far beyond just a single piece of equipment. You are looking to lower energy costs, meet environmental standards, and execute a company-wide digital transformation. A machine in a box cannot help you with that. This is why you feel you're looking for a strategic partner, not just a supplier. A transactional relationship ends when the machine is delivered. A partnership is just beginning.

A partnership approach is more critical than a simple purchase because it ensures the machine's long-term success and aligns with your strategic goals. A true partner provides comprehensive support through installation and commissioning, offers in-depth operator and maintenance training, and acts as an ongoing technical consultant to help you optimize performance, adapt to new challenges, and integrate the equipment into your larger operational strategy.

As the founder of SHJLPACK, my perspective on this was shaped by gratitude. The packing machine industry allowed me to build a factory and achieve my goals. Now, my mission is to give back by helping my clients succeed. I don't see a sale as the end of a process, but the start of a relationship. I remember working with a CEO, much like you, Javier, who was implementing a new MES platform across his entire plant. The upender he bought from us needed to integrate perfectly. Our job didn't stop at providing a communication protocol. My engineers worked directly with his IT team for two weeks, troubleshooting the data handshake and customizing our HMI screens to match the look and feel of his other systems. He wasn't just a customer; he was a partner in a shared project. That machine is now a model for how they integrate all future equipment.

Beyond the Sale: Installation and Commissioning

A successful installation is more than just bolting the machine to the floor.

- Pre-Installation Guidance: A partner provides detailed foundation drawings and utility requirements (electrical, hydraulic) long before the machine arrives. This ensures your site is prepared, avoiding costly delays.

- On-Site Supervision: We send our own engineers to your site to supervise the installation and commissioning. They work alongside your team to ensure everything is done correctly, from the initial mechanical alignment to the final safety checks. This knowledge transfer is invaluable. Your team learns the machine inside and out from the people who built it.

Empowering Your Team: Training

A machine is only as good as the people who operate and maintain it.

- Operator Training: We don't just show them which button to press. We explain the why. We train them on the proper operating sequence, how to interpret HMI warnings, and what to do in an emergency. An empowered operator is your first line of defense against downtime.

- Maintenance Training: This is where the partnership really shines. We provide hands-on training for your mechanical and electrical teams. We walk them through the preventive maintenance schedule, show them how to replace common wear parts, and teach them basic troubleshooting for the hydraulic and electrical systems. We give them the confidence to handle 90% of issues in-house.

A Long-Term Commitment: Ongoing Consultation

Your needs will change over time. Market demands shift, new regulations appear, and you will continue to push for more efficiency.

- Technical Support: When you call with a problem, you're not talking to a call center. you're talking to an engineer who understands your machine and your operation. We provide remote diagnostic support, logging into your PLC to help troubleshoot issues in real-time.

- Strategic Advice: As we are specialists in this niche, we can be a valuable resource. Whether you're considering a new automation project, looking for ways to reduce packing material waste, or need advice on meeting a new safety standard, we are there to help. Our success is directly tied to yours.

This partnership model is the final, essential piece in delivering 99.5% uptime. The best machine in the world will fail without proper installation, training, and long-term support.

Conclusion

Achieving near-perfect uptime is a result of intentional design, quality components, smart technology, and a true partnership that supports your machine and your long-term strategic goals.