Why Are South Korea's Manufacturers Replacing Manual Handling with Pallet Inverters?

Are your warehouse operations still stuck in the past? Many facilities rely on teams of workers to manually transfer heavy loads from one pallet to another. This process is not just slow and physically draining; it's a significant operational risk. Every manual lift carries the potential for a workplace injury, leading to compensation claims, lost workdays, and a drop in team morale. Damaged goods from clumsy handling also eat directly into your profits. In a fast-paced, competitive market like South Korea's, this kind of inefficiency is a major handicap that modern manufacturers can no longer afford. This is precisely why so many of them are making a change. They are moving away from outdated manual methods and investing in pallet inverters to automate the process, enhance worker safety, and protect the integrity of their products. I've seen this transformation happen many times, and the results are always impressive.

South Korean manufacturers are replacing manual handling with pallet inverters to dramatically improve operational safety, reduce costly product damage, and increase overall logistical efficiency. This strategic shift away from manual labor helps them cut direct labor costs, comply with modern safety regulations, and accelerate their entire supply chain, from the production floor to the shipping dock.

You might be thinking that a pallet inverter is just a machine for swapping pallets. But the reasons for this trend in South Korea's advanced manufacturing sector run much deeper. It’s a calculated business decision that impacts everything from employee well-being to the company's bottom line. The logic behind this investment is about building a more resilient, efficient, and profitable operation for the future. Let’s break down exactly how this equipment is transforming factory floors and why it represents a smart investment, not just another operational expense.

How Do Pallet Inverters Directly Address Rising Labor Costs and Safety Concerns?

Does the thought of a workplace injury report landing on your desk cause you stress? For any factory owner or manager, it should. Manual handling of heavy, palletized goods is one of the biggest and most predictable causes of these incidents. The costs associated with even a single injury can be staggering. You have to account for medical bills, sick leave, rising insurance premiums, and even potential legal action. On top of that, finding workers who are willing and able to perform such physically demanding tasks is becoming more difficult and expensive every year, especially in highly developed economies like South Korea.

A pallet inverter directly addresses these challenges by taking the human element out of the most dangerous part of the job. It fully mechanizes the process of lifting, rotating, and transferring loads up to thousands of kilograms. This automation creates a much safer, more predictable, and more controlled work environment for everyone.

A Deeper Look at the True Costs of Manual Labor

When we analyze the costs of manual handling, it's crucial to look beyond the hourly wage. The true financial burden is much larger. I always encourage my clients to think about both the direct and indirect costs. Direct costs are straightforward: the wages, benefits, and potential overtime for the two, three, or even four workers needed to manually restack a pallet. Indirect costs, however, are where the real financial drain occurs. These include the continuous cycle of recruiting, hiring, and training new employees for a high-turnover job. Productivity losses during training and the constant risk of operational errors add to this burden.

The most significant cost, of course, is safety. A single musculoskeletal injury from improper lifting can result in tens of thousands of dollars in medical and compensation costs. It also leads to higher insurance premiums for your entire operation. A pallet inverter transforms this equation. It turns a multi-person, high-risk task into a simple, one-person, low-risk operation. The machine does all the heavy lifting, literally.

| Cost Metric | Manual Handling (2+ Workers) | Pallet Inverter (1 Operator) |

|---|---|---|

| Direct Labor Cost | High (multiple wages) | Low (single operator) |

| Recruitment & Training | Constant, due to high turnover | Minimal, easy to operate |

| Risk of Injury | High (back, shoulder, strains) | Virtually eliminated |

| Insurance Premiums | Higher due to risk classification | Lower due to improved safety |

| Productivity Loss | Frequent, due to fatigue and injury | Consistent, high-uptime operation |

Building a Culture of Safety and Compliance

In my early days as an engineer, I visited a large food processing plant that relied entirely on manual labor for pallet swapping. The atmosphere in the cold storage area was tense, and you could see the physical strain on the workers. A year later, I returned after they had installed two pallet inverters. The change was remarkable. The same team was now operating the machines with ease. Their morale was higher, and the warehouse manager told me their minor injury reports had dropped to zero in that department. This is not just about avoiding costs; it's about showing your employees that you value their well-being. Investing in safer equipment builds a positive company culture and improves employee retention. For a business leader like Javier, who manages a large workforce, creating a safer environment is a powerful way to build loyalty and reduce turnover, which are strategic advantages in any industry.

What Are the Key Operational Efficiencies Gained from Automating Pallet Exchange?

Do you ever walk through your facility and see clear bottlenecks? Perhaps goods are piling up at the receiving dock, waiting to be transferred to your internal "clean" pallets. Or maybe finished products are stuck in the shipping area because a team is slowly and carefully restacking them onto export-grade pallets. This waiting time is pure waste. It disrupts the flow of your entire production line and creates delays that can impact customer relationships. Every minute your product sits idle, it represents a cost to your business and a risk to your delivery schedule. The reality is that manual pallet handling is a process that simply cannot keep up with the pace of modern production.

Automating the pallet exchange process with an inverter removes this bottleneck completely. It transforms a slow, labor-intensive, and unpredictable manual task into a fast, streamlined, one-person operation. This simple change unlocks significant and measurable gains in operational throughput.

The Dramatic Impact of Speed on Your Supply Chain

Let's break down a typical manual pallet swap. First, an operator has to find one or two available workers to help. They need to clear a large, safe area on the floor. Then, they begin the slow process of unstacking the entire load, box by box or bag by bag, onto the new pallet. This can easily take 10 to 15 minutes for a stable load, and much longer for unstable or heavy products. The risk of dropping and damaging goods is high throughout the process.

Now, compare that to an automated pallet inverter. A single forklift operator drives the palletized load into the machine. They press a button on the control panel. The machine securely clamps the load, rotates it 180 degrees, and lowers it so the old pallet can be removed from the top. The new pallet is placed on top, and the machine rotates the load back. The entire cycle takes about 60 seconds. You have just turned a 15-minute, multi-person task into a one-minute, one-person task. This isn't a minor improvement; it's a 10x to 15x increase in efficiency for that specific task. For a company with goals like achieving 95% equipment uptime, eliminating these final-stage packaging and shipping delays is a critical piece of the puzzle.

| Operational Stage | Manual Pallet Exchange | Automated with Pallet Inverter |

|---|---|---|

| Receiving Dock | Slow intake, potential for demurrage charges | Rapid pallet swapping, immediate availability of goods |

| Production Line Integration | Disruption, requires offline manual work | Seamless flow, can be integrated with conveyors |

| Quality Control | Difficult to inspect bottom layers | Easy access to all sides of the load for inspection |

| Shipping Dock | Slow preparation, risk of missing shipping windows | Fast pallet changes to meet export/customer specs |

Gaining Control Over Your Logistics

Efficiency isn't just about speed; it's also about control. Many of my clients in South Korea face complex pallet requirements. They might use durable plastic pallets internally for hygiene and longevity but have to ship products on cheaper, one-way wooden pallets. Or, they need to transfer goods onto heat-treated ISPM 15 pallets for international export. A pallet inverter makes these transitions effortless. It gives you the flexibility to use the right pallet for the right purpose without creating a massive operational headache. This level of control allows you to optimize pallet inventory, reduce costs, and ensure you are always compliant with customer and international standards. This is the kind of strategic control that a forward-thinking owner like Javier values.

Can Pallet Inverters Adapt to Different Industries and Product Types in South Korea?

When I talk to potential clients about pallet inverters, a common concern I hear is, "This sounds great for standard boxes on a pallet, but my products are different. They are fragile, or heavy, or bagged, or have an unusual shape." It's a valid point. Nobody wants to invest in a large piece of equipment that can only solve one specific problem. A one-trick pony is a risky investment, especially when your product lines might change or evolve over time. You need solutions that are flexible and can adapt to the diverse needs of your business.

The great news is that the versatility of modern pallet inverters is one of their biggest strengths. Over my career, I've helped design and install systems for an incredible range of products. I've seen them handle delicate glass bottles, heavy bags of cement, sealed drums of chemicals, and even frozen blocks of food. Leading manufacturers across South Korea's diverse industrial landscape—from electronics to food processing to chemicals—are proving the adaptability of this technology every single day.

Engineered for Flexibility Across Industries

The key to this adaptability lies in the machine's design and features, which can be tailored to specific applications. It’s not a one-size-fits-all solution. For example, for a client in the pharmaceutical industry, we provided a pallet inverter made entirely of stainless steel. This ensured it could be used in a cleanroom environment without any risk of contamination. For a chemical manufacturer handling heavy bags, the focus was on high load capacity and very strong, secure clamping to prevent any load shifting during rotation.

Here’s a look at how these machines are adapted for different sectors:

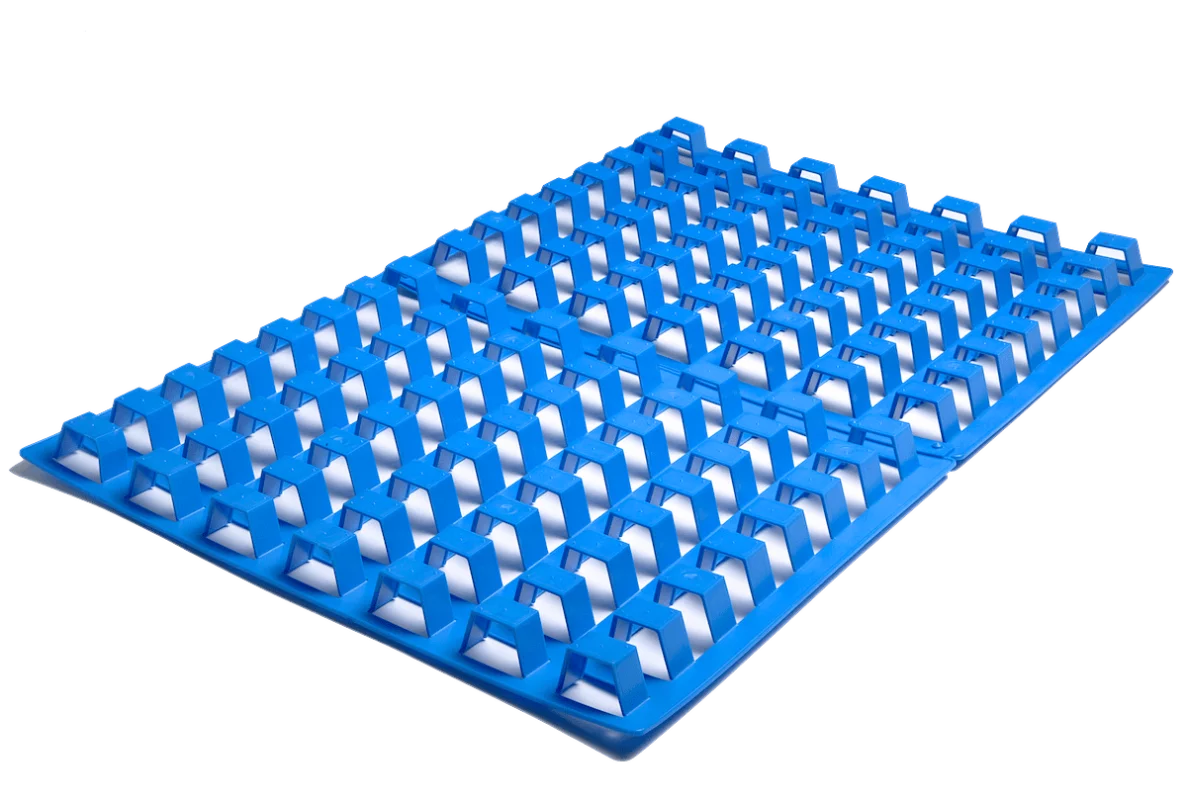

- Food & Beverage: The primary need here is hygiene. Pallet inverters allow companies to easily switch from external wooden pallets to sanitized in-house plastic or metal pallets. The clamping pressure can be adjusted to be very gentle, protecting products like bottled drinks or bagged snacks.

- Pharmaceuticals: In this highly regulated industry, preventing contamination is everything. Pallet inverters can be built with smooth, easy-to-clean surfaces and integrated into controlled environments to maintain sterility.

- Chemicals & Agriculture: For companies handling bulky bags or drums, stability and safety are paramount. Inverters with robust clamping systems and a full 180-degree rotation ensure that even unstable loads can be handled securely.

- General Manufacturing: In a steel mill like Javier's, there may be palletized loads of finished components, spare parts, or supplies. A heavy-duty pallet inverter can easily manage these loads, streamlining the internal logistics and preparation for shipping.

Customization: The Key to a Perfect Fit

A good equipment partner doesn't just sell you a machine; they work with you to understand your specific product and process. This is where customization becomes critical.

| Customization Feature | Benefit and Application |

|---|---|

| Adjustable Clamping Pressure | Protects fragile goods from being crushed; provides strong grip for heavy loads. Essential for companies with diverse product lines. |

| Loading Style | Can be loaded directly from the floor with a hand pallet truck or raised for standard forklift access, fitting into any existing workflow. |

| Stainless Steel Construction | Required for food, beverage, and pharmaceutical industries to meet strict hygiene and sanitation standards. |

| Automation Integration | Can be equipped with photo-eye sensors and linked to automated conveyor systems for a fully hands-off operation. |

This ability to customize is central to our philosophy at SHJLPACK. We see ourselves as problem-solvers. When a client comes to me, my goal is to provide a total solution that perfectly matches their unique challenge. This ensures the equipment they invest in will deliver value for many years to come, regardless of how their business evolves.

What is the Real ROI of a Pallet Inverter Beyond Simple Pallet Swapping?

As a business owner myself, I know that every significant purchase must be justified. The first thing any practical leader asks is, "What is the return on my investment?" It's easy to see the upfront cost of a new machine on a quote. But focusing only on that initial price tag is a mistake. It’s like looking at the tip of the iceberg while ignoring the massive, impactful part below the surface. The true value of a strategic investment is measured by the accumulated cost savings, efficiency gains, and risk reduction it provides over its entire operational lifespan.

The real ROI of a pallet inverter extends far beyond the simple act of swapping one pallet for another. It is a strategic tool that generates returns in areas that many business owners initially overlook. When I consult with clients, whether they are in the steel industry like Javier or in another sector, I always urge them to analyze the total financial picture.

Calculating the Full Financial Return

A comprehensive ROI calculation for a pallet inverter reveals a compelling business case. Let's break down the sources of return, both in direct cost savings and in revenue-enhancing gains. This is the kind of analysis a pragmatic leader like Javier would conduct before any major capital expenditure.

1. Direct Cost Savings:

- Labor Reduction: This is the most obvious saving. You replace a two-to-three-person manual team with a single, efficient machine operator. The annual salary savings alone can often justify the machine's cost in a short period.

- Elimination of Pallet Rental Costs: Many companies spend a fortune renting high-quality pallets (like those from CHEP or LPR) for their supply chain. With an inverter, you can receive goods on rental pallets, immediately transfer them to your own cheaper, captive pallets for internal use, and send the expensive rental pallets back right away. This eliminates rental fees and the costs associated with lost or damaged rental pallets.

- Reduced Product Damage: Manual handling leads to dropped boxes, torn bags, and dented containers. A pallet inverter handles loads with smooth, controlled, and consistent pressure. Reducing product damage from 1% down to 0.1% can translate into tens of thousands of dollars saved annually.

- Lower Insurance Premiums: By eliminating a primary cause of workplace injuries, you create a safer risk profile for your company, which can lead to direct reductions in your workers' compensation insurance costs.

2. Strategic and Revenue-Generating Value:

- Increased Throughput: Faster processing means you can move more goods through your facility without adding more staff or space. This allows you to fulfill more orders, meet tighter deadlines, and increase your overall revenue capacity.

- Enhanced Operational Flexibility: The ability to quickly swap pallets allows you to say "yes" to customer requests that you might have previously declined due to operational constraints.

- Improved Employee Morale and Retention: Investing in modern, safe equipment shows your employees you care. This leads to higher morale, lower turnover, and a more skilled, stable workforce.

| ROI Factor | Description | Impact on Javier's Goals |

|---|---|---|

| Pallet Cost Optimization | Use cheaper in-house pallets, return rental pallets faster. | Reduces operating costs. |

| Reduced Product Damage | Protects finished goods during handling. | Increases profit margins. |

| Labor Re-allocation | Move workers from manual labor to value-added tasks. | Reduces costs, improves efficiency. |

| Increased Throughput | Process more pallets per hour in shipping/receiving. | Helps achieve 95% uptime target. |

| Enhanced Safety | Drastically reduces risk of manual lifting injuries. | Contributes to lower operational costs. |

When you add all these factors together, the payback period for a pallet inverter is often much shorter than people expect, typically between 12 to 24 months. After that, the machine continues to generate pure profit for your business year after year.

Conclusion

Investing in a pallet inverter is not just a simple equipment upgrade. It is a strategic move toward greater safety, higher efficiency, and improved profitability that transforms your logistics operation.