Choosing the Right Pallet Inverter for Germany's Demands in Precision Automation in Lean Manufacturing Plants

Are you running a lean manufacturing plant in Germany? You know that every second and every square meter counts. But you might have a hidden bottleneck in your logistics: handling and swapping pallets. This process seems simple, but it can cause delays, risk worker injury, and even damage your products. These small issues add up. They eat into your profits and undermine the very principles of precision and efficiency that German industry is built on. You're trying to build a world-class automated system, but this manual weak link is holding you back. A pallet inverter is more than just a piece of equipment; it's a strategic investment in automation that solves this problem directly. It can transform a slow, risky manual task into a fast, safe, and automated part of your production line.

The best pallet inverter for Germany's demanding lean manufacturing environment is one that integrates seamlessly with Industry 4.0 systems, is certified to meet strict TÜV and CE safety standards, contributes to your sustainability targets through energy efficiency, and is highly customized to your specific products and facility layout. Choosing the right machine means finding a partner who understands these requirements and can deliver a solution, not just a product. It's about boosting automation, ensuring safety, and supporting your green initiatives all at once.

I've spent my entire career in the packing and handling industry, from my early days as an engineer on the factory floor to building my own company, SHJLPACK. I’ve seen firsthand how the right equipment can make or break an operation. It's not just about the machine's specs on paper. It's about how it performs in the real world, under pressure. Germany represents the peak of precision manufacturing, and selecting equipment for this market requires a special level of attention. In this article, I will break down the critical factors you need to consider. We will go beyond the basics and look at how a pallet inverter becomes a key part of your automation, safety, and sustainability strategy. Let's walk through this together.

How does a pallet inverter fit into Germany's Industry 4.0 vision?

You are investing heavily in creating a smart factory. Your systems are designed for data exchange and automation. But if your material handling still relies on manual labor or isolated machines, you have a critical gap in your data chain. This disconnect creates a blind spot in your operations. It means your expensive Manufacturing Execution System (MES) is working with incomplete information, preventing you from achieving true, end-to-end optimization. A modern pallet inverter is the solution. It is not just a mechanical tool; it is an intelligent, connected device that plugs this gap. It becomes an active participant in your Industry 4.0 ecosystem, feeding real-time data and automating a crucial logistical step.

A pallet inverter fits into Germany's Industry 4.0 vision by evolving from a standalone machine into a connected, data-producing asset. It integrates directly with your plant's MES and Warehouse Management Systems (WMS), uses sensors to provide real-time status updates, and works in concert with other automated systems like AGVs. By doing this, it helps create the fully transparent, efficient, and automated smart factory that is the core of the Industry 4.0 concept.

Diving Deeper into Smart Integration

To truly appreciate how a pallet inverter supports Industry 4.0, we need to look at three key areas: data connectivity, automation synergy, and predictive capabilities. A basic machine just turns a pallet. An Industry 4.0-ready machine becomes a source of valuable intelligence that drives efficiency across your entire plant. This is something I've helped many clients achieve, turning a simple handling task into a strategic advantage. It’s about making every piece of equipment a team player in your digital factory.

Data Integration and Connectivity

The foundation of a smart factory is data. A modern pallet inverter must be able to speak the same language as your other systems. This starts with the Programmable Logic Controller (PLC), the machine's brain. We ensure our machines can communicate over standard industrial protocols like PROFINET or OPC UA, which are common in German facilities. This allows the pallet inverter to send a constant stream of data to your MES or ERP system. What kind of data? Things like cycle times, number of pallets processed, load weight verification, and any error codes. This information is no longer locked in the machine; it becomes visible to your entire operation. You can track throughput in real time, identify bottlenecks, and verify that the correct products are being handled, all from your central control room.

Automation and Robotic Synergy

In a lean, automated plant, you want to eliminate manual hand-offs. This is where a pallet inverter truly shines within an automated workflow. We design our systems to integrate perfectly with Automated Guided Vehicles (AGVs) or robotic arms. An AGV can deliver a pallet to the inverter's input station, signal that it's ready, and the inverter takes over. It performs the 180-degree rotation, exchanges the pallet, and then signals the AGV or another conveyor system to pick up the processed load. This creates a fully autonomous work cell. There is no need for a forklift operator to intervene. This not only reduces labor costs but also increases safety and speed, creating a predictable, repeatable process that is essential for lean manufacturing.

Predictive Maintenance with IoT

Equipment downtime is the enemy of efficiency. This is a major challenge for plant owners like Javier Morales, who aim for 95% uptime. An Industry 4.0-ready pallet inverter uses IoT sensors to prevent unexpected failures. We can embed sensors to monitor the health of critical components. For example, vibration sensors on the motors, temperature sensors on the hydraulic power pack, and pressure sensors in the hydraulic lines. This data is analyzed to detect patterns that suggest a future failure. Your maintenance team receives an alert before the machine breaks down, allowing them to schedule repairs during planned downtime. This shifts your maintenance strategy from reactive to predictive, a core goal for any modern manufacturing leader.

| Feature | "Dumb" Pallet Inverter | Industry 4.0 Ready Pallet Inverter |

|---|---|---|

| Connectivity | Standalone, no network connection | PLC with PROFINET/OPC UA for MES/ERP integration |

| Data Output | None, or basic cycle counter | Real-time data on cycle time, weight, errors |

| Automation | Requires manual loading/unloading by forklift | Integrates with AGVs and robotic cells |

| Maintenance | Reactive (fix when it breaks) | Predictive (IoT sensors alert before failure) |

What are the key safety standards a pallet inverter must meet in Germany?

You have identified the need for a pallet inverter. It promises to boost efficiency. But then a major concern arises: navigating Germany's strict safety regulations. The thought of installing a machine that might not be compliant is daunting. A single safety violation could result in heavy fines, a complete halt in production, and serious damage to your company's reputation. Importing and operating non-compliant equipment is a risk no business can afford to take, especially in a market that values safety as much as Germany does. The only secure path forward is to understand these standards deeply and demand full compliance from your equipment supplier. This ensures your investment is safe, legal, and protects your most valuable asset: your people.

To operate legally and safely in Germany, a pallet inverter must, at a minimum, comply with the EU's Machinery Directive 2006/42/EC and proudly display the CE mark. This is not just a sticker. It signifies that the machine's design and construction have followed harmonized European standards, specifically ISO 12100 for comprehensive risk assessment and ISO 13849 for the safety of its control systems. For many German companies, seeking an additional third-party certification from a body like TÜV provides an extra layer of confidence that the machine has been rigorously tested and verified.

Diving Deeper into German Safety Compliance

Safety isn't just a box to tick; it's a fundamental part of machine design. In my years of manufacturing equipment, I've learned that building a safe machine from the ground up is far more effective than adding safety features as an afterthought. For the German market, this philosophy is not just good practice—it's a requirement. Let's break down what these standards mean in practical terms for your pallet inverter.

The CE Mark: Your Ticket to Entry

The CE marking is your basic license to operate machinery in the European Union, including Germany. As a manufacturer, SHJLPACK is responsible for ensuring our equipment meets all relevant directives. For a pallet inverter, the Machinery Directive is the most important one. This means we must conduct a thorough risk assessment for every possible hazard, from crushing and shearing points to electrical and hydraulic dangers. The results of this assessment and the steps we took to mitigate each risk are documented in a detailed technical file. When you purchase a machine from a reputable supplier, you have the right to request this documentation to be sure that due diligence was performed. A missing CE mark is a red flag you should never ignore.

Critical ISO Standards You Must Know

The CE mark is based on compliance with specific "harmonized standards." For a pallet inverter, a few are particularly important:

- ISO 12100 (Risk Assessment): This is the foundational standard. It forces us to think like an operator, a maintenance technician, and anyone else who might interact with the machine. We identify potential hazards, estimate the level of risk, and then implement safety measures to eliminate or reduce that risk. This could involve fixed guards, light curtains, or two-hand controls.

- ISO 13849 (Safety of Control Systems): This standard deals with the reliability of the safety functions themselves. It's not enough to have an emergency stop button; that button and its entire circuit must be designed to work reliably when needed. We design control systems to a specific Performance Level (PL), such as PLd or PLe, which defines the system's ability to perform a safety function under foreseeable conditions. This involves using dual-channel, monitored safety components to prevent a single point of failure from causing a dangerous situation.

- IEC 60204-1 (Electrical Safety): This standard covers all the electrical equipment on the machine. It dictates requirements for proper wiring, grounding, overcurrent protection, and control panel layout to prevent electrical shocks and fires.

The Added Value of TÜV Certification

While the CE mark is a self-declaration, a certificate from a Notified Body like TÜV SÜD or DEKRA is an independent verification. It means an expert third party has inspected the machine, reviewed the technical file, and tested the safety functions. For a cautious and pragmatic business leader like Javier, this provides immense peace of mind. It's a clear signal that the machine doesn't just meet the minimum requirements but has been scrutinized by one of the world's most respected safety organizations. It's an investment in risk reduction.

| Safety Requirement | What It Is | Why It Matters in Germany |

|---|---|---|

| CE Marking | Manufacturer's declaration of conformity with EU directives. | A legal prerequisite for selling and operating machinery in the EU. |

| Technical File | A comprehensive document detailing design, risk assessment, and test results. | Proof that the manufacturer has done their due diligence. |

| Risk Assessment (ISO 12100) | A systematic process to identify and mitigate all potential hazards. | The foundation of a safe machine design, required by law. |

| Control System Safety (ISO 13849) | A standard for ensuring safety circuits (e-stops, light curtains) are reliable. | Prevents accidents caused by the failure of a safety function. |

| Electrical Safety (IEC 60204-1) | Rules for the safe design and installation of the machine's electrical system. | Protects against electrical shock and fire hazards. |

| Physical Guarding | Fences, safety gates, and enclosures that prevent access to moving parts. | The first line of defense against contact with dangerous machine parts. |

How does pallet inverter selection impact sustainability goals in German manufacturing?

Your company has set ambitious goals to reduce its carbon footprint and operate more sustainably. When you look at new equipment, you might see it primarily as an energy consumer. However, this view can cause you to miss a key opportunity. Ignoring the environmental impact of your internal logistics can undermine your larger sustainability efforts. An inefficient machine wastes electricity, while rough handling can damage products, creating unnecessary waste. These factors hurt both the planet and your bottom line. The right pallet inverter is not a liability. It's a tool that can actively help you achieve your energy reduction and waste minimization targets.

Choosing the right pallet inverter directly impacts your sustainability goals in several positive ways. By selecting a machine with an energy-efficient drive system, you lower your plant's overall electricity consumption. Gentle and precise handling mechanisms significantly reduce product damage, which cuts down on material waste. Furthermore, pallet inverters make it easy to switch from single-use wooden pallets to durable, reusable plastic or metal ones, supporting a circular economy. This aligns perfectly with Germany’s strong focus on green manufacturing and reducing industrial environmental impact.

Diving Deeper into Green Logistics

Sustainability in manufacturing is about more than just emissions stacks and water treatment. It extends all the way to the factory floor, to every machine that uses power or handles materials. This is a conversation I have frequently with forward-thinking clients. They want to know how our equipment can contribute to their goals, like Javier's target of reducing unit energy consumption by 10%. A well-chosen pallet inverter can be a surprisingly effective tool in your green arsenal.

Energy Efficiency by Design

The biggest direct environmental impact of a pallet inverter is its energy consumption. The technology used to power the machine makes a huge difference. Traditional pallet inverters often use hydraulic systems that run continuously, consuming power even when the machine is idle. A more sustainable choice is an all-electric model, which only draws significant power during the rotation cycle. For hydraulic systems, we can incorporate energy-saving features. For example, a hydraulic accumulator can store pressurized fluid, allowing the main pump to shut down during idle periods and kick in only when needed. Another option is to use a variable frequency drive (VFD) on the motor for either hydraulic or electric systems. The VFD adjusts the motor's speed to match the required load, drastically cutting energy use compared to a motor that runs at full speed all the time.

Reducing Product and Pallet Waste

Waste reduction is a core pillar of sustainability. Every product that gets damaged during handling is a waste of raw materials, energy, and labor. We can design our pallet inverters with adjustable clamping pressure and soft-touch surfaces to handle delicate goods without causing crushing or cosmetic damage. I once worked with a client in the beverage industry who was losing thousands of euros a year due to bottles breaking during pallet transfers. A customized inverter with precise pressure control solved the problem overnight. Beyond product waste, there is pallet waste. Many companies want to move away from disposable wood pallets. A pallet inverter is the key enabler for this shift. It allows you to easily transfer incoming goods from cheap shipping pallets onto your high-quality, reusable in-house pallets, which can be used for years, supporting a circular economy model.

Lean Manufacturing is Green Manufacturing

The principles of lean manufacturing and sustainability are deeply connected. Lean is focused on eliminating all forms of waste, or "Muda." This includes wasted energy, wasted materials, and wasted motion. An efficient, automated pallet inverter attacks all three. It consumes less energy, it prevents product damage, and by integrating into an automated line, it eliminates the wasted motion and fuel consumption of a forklift driving back and forth. By making your logistics leaner, you are inherently making them greener. This directly supports the goal of reducing overall operational costs while improving your environmental scorecard.

| Feature | Model A: Basic Inverter | Model B: Eco-Efficient Inverter |

|---|---|---|

| Drive System | Standard Hydraulic (constant run) | All-Electric with VFD |

| Energy Per Cycle | 0.75 kWh | 0.30 kWh |

| Idle Power Draw | High | Near-zero |

| Handling Control | Fixed Clamping Pressure | Adjustable, sensor-based pressure |

| Product Damage Rate | ~1.5% | <0.2% |

| Pallet Compatibility | Standard pallets | Enables easy switch to reusable plastic/metal pallets |

Why is customization crucial for pallet inverters in Germany's diverse industries?

You are evaluating standard, off-the-shelf pallet inverters for your facility. But you have a nagging feeling that a one-size-fits-all solution is a gamble. Your products have unique dimensions, your pallets are a specific type, and your factory layout has its own constraints. Attempting to force a standard machine into a highly specialized process is a recipe for inefficiency. It can create new bottlenecks, lead to product damage, and frustrate your operators. You may even find yourself changing your processes to accommodate the machine's limitations, which is the exact opposite of what automation should do. The solution is to work with a supplier that treats customization as a standard part of their process. This ensures the pallet inverter integrates perfectly and becomes a seamless, productive part of your unique operation.

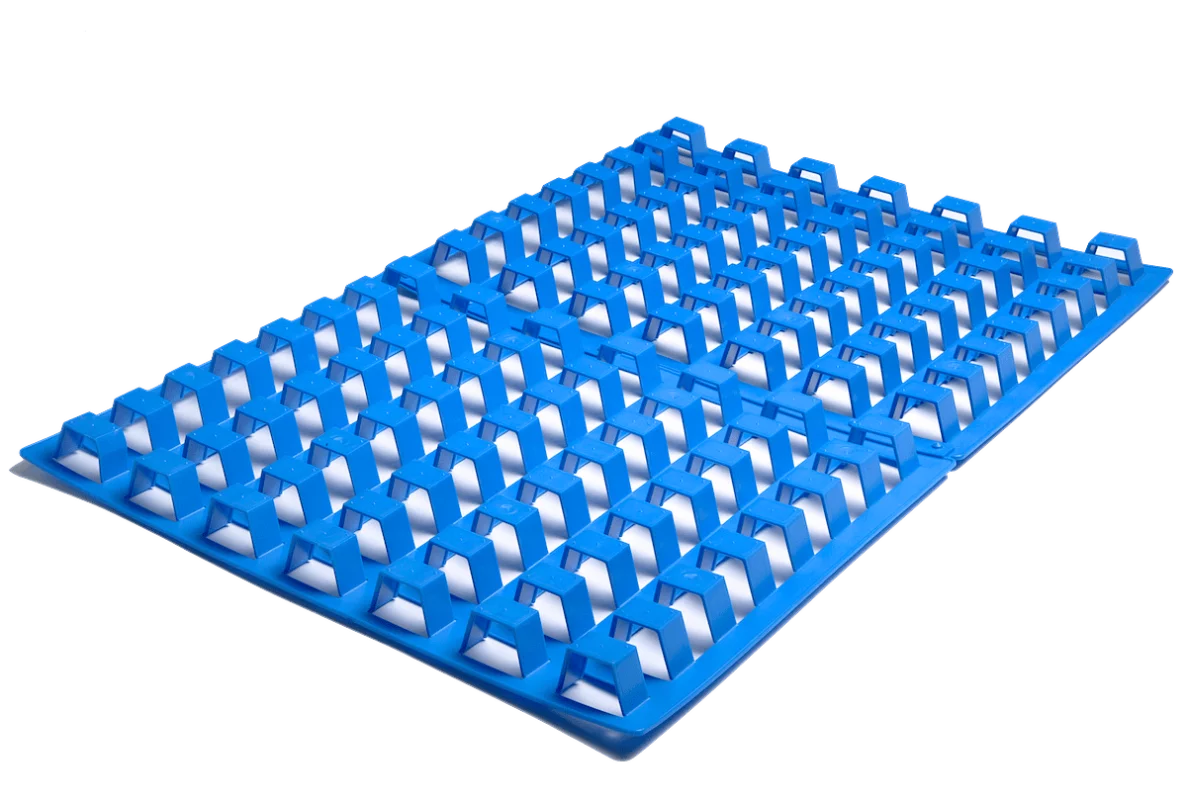

Customization is critical for pallet inverters in Germany because of the sheer diversity of the country's manufacturing sector. From heavy steel coils in the Ruhr Valley to sterile pharmaceutical vials in Bavaria, no single machine can meet every need. The loads vary dramatically in size, weight, shape, and fragility. The operating environments range from standard warehouses to explosive atmospheres or hygienic cleanrooms. Customizing the inverter's clamping mechanism, dimensions, materials, and control systems is the only way to guarantee optimal performance, absolute safety, and seamless integration into these specialized production lines.

Diving Deeper into Tailor-Made Solutions

As an engineer, this is the part of the job I love most. Taking a client's unique challenge and designing a specific solution for it is incredibly rewarding. A standard machine solves a standard problem. But in a competitive market like Germany, most problems aren't standard. At SHJLPACK, our slogan is "TOTAL SOLUTION FOR WRAPPING MACHINE" because we don't just sell machines; we engineer solutions. Customization isn't an expensive add-on; it's the core of how we provide value. Let's look at what this means in practice.

Adapting to Your Unique Load

The first step is always to understand the load itself. A pallet inverter for a steel mill owner like Javier, who handles heavy, stable steel coils, is completely different from one designed for a food company handling fragile boxes of snacks. For Javier's steel coils, we would design a heavy-duty frame and a powerful clamping system to handle weights of 2,000 kg or more. For the snack company, the focus would be on gentle handling, with wide platens to distribute pressure and a highly sensitive hydraulic or electric system to avoid crushing the packages. I remember a client who manufactured large, delicate solar panels. We designed a special inverter with full-surface foam padding and a very slow, controlled rotation speed to prevent any stress on the panels. This level of customization is what prevents damage and waste.

Fitting into Your Facility's Footprint

Not every factory has endless open space. Often, a pallet inverter needs to fit into a very specific location with a tight footprint, low ceiling clearance, or existing conveyor lines. A standard machine might simply not fit. We frequently modify the physical dimensions of our inverters to suit a client's facility. This could mean designing a low-profile model, changing the orientation of the loading and unloading access from front-to-back to side-to-side, or creating custom ramps and integration points to connect with their current material flow. This ensures the machine enhances the workflow rather than disrupting it.

Meeting Special Environmental Needs

Germany's industries have diverse environmental requirements. A pallet inverter destined for a pharmaceutical or food processing plant must meet strict hygiene standards. In these cases, we build the machine using stainless steel (like 304 or 316 grade) and ensure all components are wash-down ready, with sealed bearings and waterproof electrical enclosures. Conversely, a client in the chemical or petroleum industry might need to operate the machine in a potentially explosive atmosphere. For them, we would build an ATEX-compliant inverter, using specialized explosion-proof motors, sensors, and wiring to ensure safe operation. This isn't just a feature; it's a critical safety requirement that demands expert engineering.

| Customization Area | Your Requirement (Example) | Possible Customizations We Provide |

|---|---|---|

| Load Type | Fragile glass bottles on pallets | Soft-touch clamping platens, variable pressure control, smooth acceleration/deceleration. |

| Load Dimensions | Oversized or very tall loads | Increased opening range, extended base frame, custom top clamp design. |

| Load Weight | Heavy (e.g., 2,500 kg engine blocks) | Reinforced steel frame, uprated hydraulic/electric drive, heavy-duty chains. |

| Facility Footprint | Limited floor space | Compact machine design, side-loading configuration, integration with vertical lifts. |

| Environment | Hygienic Food-Grade Area | Full stainless-steel construction, wash-down rated components, food-safe hydraulic fluid. |

| Integration | Fully automated line with AGVs | AGV docking guides, automated safety gate sequencing, communication handshake with WMS. |

My Insight: From an Engineer's Notebook

I remember working with a client in Germany, a mid-sized steel service center. Their manager, a man named Klaus, reminded me a lot of the profile of Javier Morales. He was incredibly sharp, pragmatic, and focused on ROI for every single euro he spent. He initially contacted us for a simple pallet inverter. He saw it as a necessary tool to flip pallets of sheet steel for inspection. A standard machine would have "worked," but I knew we could do better.

During our visit, I didn't just look at the spot where the inverter would go. I walked his entire finishing line, from where the coils were cut to where the final pallets were staged for shipping. I saw the operators struggling to manually re-stack pallets, the occasional scratched steel sheet from rough handling, and the small delays that added up throughout the day. His challenge wasn't just flipping pallets; it was a series of small inefficiencies that were eating into his profit margins.

Instead of just quoting him a standard machine, I sat down with him and my notepad. We sketched out his entire workflow. I proposed a customized, integrated solution. We designed an inverter with a powered conveyor in-feed and out-feed that could be loaded directly by their overhead crane. We added sensors that measured the weight of each pallet, verifying it against the work order in their MES. This wasn't just a pallet inverter anymore; it was an automated quality control and logistics checkpoint.

Klaus was skeptical at first about the higher initial cost. But I showed him the numbers. The automated system would eliminate one full-time operator position on that line. The precise handling would reduce product scratches, saving thousands per year in scrap. And the data integration would give him real-time visibility, helping him achieve the kind of uptime and efficiency he was aiming for. He saw that we weren't just selling him a machine; we were providing a total solution to a bigger problem. We won the project, and a year later, Klaus told me it was one of the best investments he'd ever made. That experience taught me a valuable lesson: a true partner doesn't just answer the question you ask. They help you find the right question to begin with.

Conclusion

Choosing the right pallet inverter for Germany means seeing it as a strategic tool for automation, safety, and sustainability. Your ultimate success depends on finding a knowledgeable partner, not just a supplier.