How to Choose the Mold Upender Near Me

Are you responsible for handling heavy, expensive molds in your facility? You know that turning them manually is not just slow, but dangerously unsafe. It puts your team at risk and threatens your valuable tooling with damage. The pressure to maintain a safe and efficient workflow is constant, but finding a reliable local supplier who understands these high stakes can feel like searching for a needle in a haystack. A single misstep in this process, a single accident, could trigger catastrophic downtime, costly repairs, and a serious safety incident that reverberates through your entire operation. The wrong machine, even one that seems like a bargain, can quickly become a production bottleneck and a constant source of stress.

The best way to choose a mold upender "near you" is to look beyond geographic proximity and focus on a supplier's technical expertise, their capacity for rapid after-sales support, and their proven understanding of your industry's rigorous safety standards. The goal is to find a strategic partner who can deliver a customized, reliable solution with quick-response service, not just the company with the closest warehouse.

Finding a "local" supplier is about much more than a pin on a map. It's a strategic decision that impacts your operational efficiency, safety, and long-term costs. A true local partner offers accessibility, deep operational understanding, and responsive support that a distant manufacturer simply cannot match. Let's break down the critical factors you need to analyze to ensure your investment in a mold upender is a sound one that will pay dividends for years to come.

What technical specifications are non-negotiable?

You’re looking at a catalog filled with different mold upenders, each with a long list of technical data. It can be overwhelming. The fear of making the wrong choice is real, because choosing a machine with the wrong capacity or an incorrectly sized table doesn't just mean you made a poor purchase—it means you might have bought a massive, useless piece of steel that is a danger to your operation. Imagine the moment an upender fails under the weight of your multi-ton mold, or you discover it's just a few centimeters too small for your largest tool. The consequences are dire, impacting everything from your production schedule to the safety of your team.

The most critical, non-negotiable technical specifications for any mold upender are its load capacity, table size, tilting angle, and power system. You must select these based on the specifications of your heaviest and largest molds, always incorporating a safety margin of at least 20-25% on the load capacity to ensure safe and reliable operation under all conditions.

Diving Deeper into the Core Specifications

When I evaluate a machine, I look at it from an engineer's perspective. The numbers on the spec sheet must translate to real-world performance and, most importantly, safety.

Load Capacity: Your First Line of Defense

The load capacity isn't just a number; it's the foundation of the machine's safety. When a manufacturer states a 10-ton capacity, you need to know what that really means. I always insist on a safety factor of at least 1.25, meaning a 10-ton rated machine should be structurally and mechanically capable of handling 12.5 tons. Why? Because loads are not always perfectly centered. The dynamics of lifting and tilting can create momentary stresses that exceed the static weight of the mold. I once visited a client who had purchased a low-cost upender rated for their exact maximum mold weight. It worked for a few months, but one day, a slightly off-center load caused a structural weld to fail. The resulting damage to their million-dollar mold cost them ten times the savings they thought they had achieved.

Table Size: It's More Than Just Length and Width

The table dimensions must accommodate the footprint of your largest mold, but that's just the starting point. You need to consider:

- Overhang: Will any part of the mold hang over the edge? This can create an unbalanced load and a serious safety hazard.

- Loading/Unloading: How will you place the mold on the upender? With an overhead crane or a forklift? The table design and the space around the machine must allow for clear, unobstructed access. A poorly designed table can add minutes to every single mold handling operation, which adds up to significant lost time over a year.

- Clamping: Does the machine have integrated clamps? Are they suitable for your mold shapes? Securely holding the mold is just as important as lifting it.

Power System: Hydraulic vs. Electromechanical

The choice between a hydraulic and an electromechanical system depends on your specific needs for power, precision, and your workshop environment. Neither is universally "better," but one will be better for you.

| Feature | Hydraulic Upender | Electromechanical Upender |

|---|---|---|

| Power & Speed | Excellent for very heavy loads, providing smooth and powerful force. Generally has a faster tilting cycle. | Highly precise and controlled movement. Ideal for applications where exact positioning is critical. |

| Maintenance | Requires regular checks for hydraulic fluid levels, leaks, and filter changes. | Simpler maintenance, focused on the gearbox and motor. No risk of messy fluid leaks. |

| Initial Cost | Often has a lower upfront cost, especially for machines with very high load capacities. | Can be more expensive initially due to the cost of the gear motor and control systems. |

| Environment | The risk of oil leaks makes it less suitable for cleanroom environments or food-grade applications. | Much cleaner operation with no hydraulic oil. A better choice for environmentally sensitive areas. |

Ultimately, a deep discussion with the supplier's engineers about these technical points will reveal their level of expertise. If they can't confidently answer these questions, they are not the right partner.

How does "near me" translate to better service and support?

Imagine this scenario: your main production line is down because the mold upender has failed. Every hour that ticks by, your production targets are slipping further away, and costs are mounting. You call your supplier for support, only to discover they are in a different time zone, their support staff doesn't speak your language fluently, and the earliest a technician can be on-site is in three days, pending flight availability. The frustration and feeling of helplessness in that situation are immense.

A supplier who is truly "near me" provides better service by offering faster technician dispatch for urgent repairs, significantly lower travel costs for service calls, a local inventory of critical spare parts, and on-site training delivered in your team's native language. This proximity is the foundation of a strong strategic partnership and your best defense against costly, extended downtime.

Diving Deeper into the Value of Local Support

For a business leader like you, every decision comes down to ROI. The value of local support isn't an intangible feeling; it has a hard, measurable impact on your bottom line.

The Real-World Calculation of Downtime

In a high-capacity steel mill, the cost of downtime is not trivial. It's a cascade of losses. Let’s say a critical mold change is delayed by 8 hours because your upender is broken and you're waiting for remote support.

- Lost Production: If your line produces 250 tons per hour at a value of $800/ton, that's $200,000 in lost revenue per hour. An 8-hour stoppage is a $1.6 million problem.

- Idle Labor: Your crew is on the clock, unable to work.

- Supply Chain Disruptions: Your failure to produce impacts the client waiting for your steel.

The true value of a local supplier is their ability to shrink that 8-hour downtime to 2 hours. That difference is your ROI.

The Local Service Agreement Checklist

When you talk to a potential supplier, don't accept vague promises of "great service." Demand specifics.

- Guaranteed On-Site Response Time: What is their contractual obligation? Can a qualified technician be at your gate in 4 hours? 12 hours? 24 hours? Get this in writing. This is your insurance policy against extended downtime.

- Local Spare Parts Inventory: This is a deal-breaker for me. I once worked with a client in Mexico who bought a machine from a European company. A simple proximity sensor failed. The part cost $50, but because the supplier had no local stock, it took three weeks to ship a replacement from Germany. The line was down the entire time. A local partner should stock critical, high-wear components like motors, sensors, hydraulic pumps, and control boards. Ask for a list of their locally stocked parts.

- Local Language and Culture: Effective training and troubleshooting require clear communication. A local team that can train your operators and maintenance staff in Spanish, for example, is far more effective than trying to decipher a technical manual translated from another language or talking to a support agent on a crackly international call.

A true local partner is invested in your uptime. They move from being a reactive, break-fix vendor to a proactive partner who helps you schedule preventive maintenance and plan for future needs. This aligns directly with the goal of predictive maintenance and increasing equipment uptime to your target of 95%.

How do I evaluate a supplier's quality and reliability?

Every supplier's website you visit and every brochure you read will claim their machine is the best, the most reliable, and the highest quality. The marketing is always professional and polished. But as an experienced leader, you know how crucial it is to see past the sales pitch and understand the true substance of the company you are dealing with. Making a multi-thousand-dollar investment based on a slick presentation is a massive gamble. A poor-quality machine will become a thorn in your side, plaguing you with constant breakdowns, creating safety risks, and draining your maintenance budget, completely erasing any savings you made on the initial purchase.

To properly evaluate a supplier's quality and reliability, you must dig deeper. The best methods are to request and speak with customer references in your industry, conduct a thorough factory audit (either in-person or virtually), closely inspect the quality of their welds and key components, and verify their quality and safety certifications, such as ISO 9001 or CE.

Diving Deeper into the Vetting Process

I have spent my entire career in this industry, both on the factory floor and as a business owner. Here is the practical checklist I use to separate the serious manufacturers from the simple traders.

1. Customer References are Non-Negotiable

Don't just accept a list of company names. Ask for references from businesses that are similar to yours—in your country, in the steel industry, and with a similar operational scale. When you call them, ask pointed questions:

- "How has the machine performed since installation? What has the real uptime been?"

- "Describe your experience with their installation and commissioning team."

- "When you had a problem, how fast and effective was their after-sales service?"

- "Were there any unexpected costs or issues?"

- "Knowing what you know now, would you buy from them again?"

The answer to that last question is the most telling one of all.

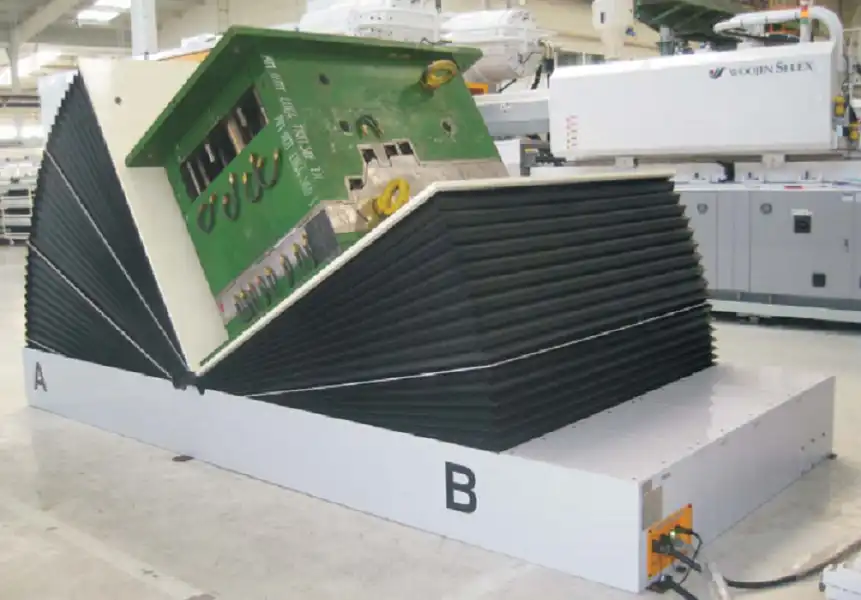

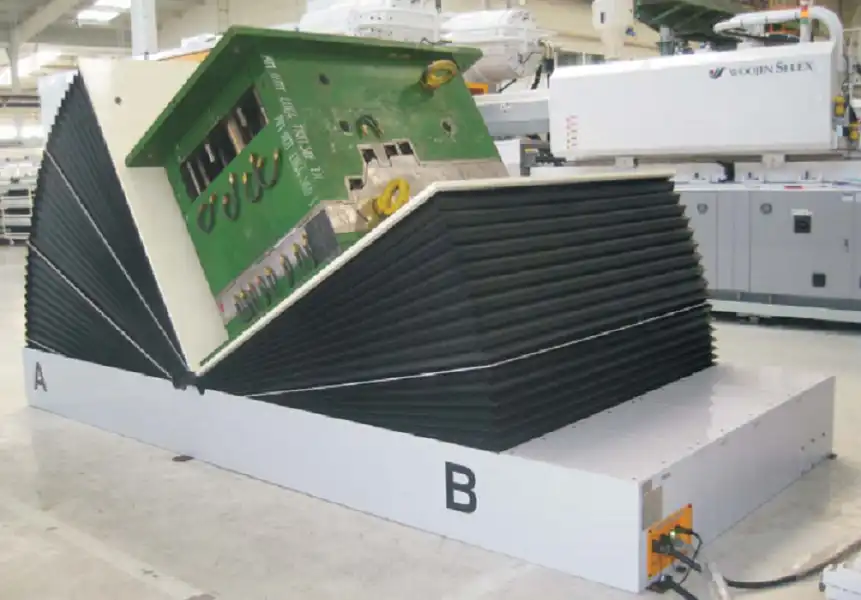

2. The Factory Audit: See Quality with Your Own Eyes

Whether you go in person or do a detailed virtual tour, a factory audit reveals everything.

- Workmanship: Look at the welds. Are they clean, uniform, and penetrating? Or are they sloppy and piled on top of the metal? Poor welding is a sign of poor quality control and a future structural failure waiting to happen.

- Materials and Machining: What grade of steel are they using for the main structure? Ask to see their raw material storage. Look at their machining equipment. Do they have modern CNC machines for precision parts, or are they relying on outdated, manual equipment?

- Quality Control Process: Ask to see their QC station. How do they test every machine before it ships? They should be performing a full functional test with a load that is at or above the machine's rating. If they can't show you a documented QC procedure for every single machine, walk away.

- The Engineering Team: I always make it a point to speak with their lead engineer. I want to know if they truly understand the forces and stresses involved. Can they have an intelligent conversation about customization, safety features, and integration with my existing workflow? A strong engineering department is the heart of a reliable equipment manufacturer.

3. Component Brands Matter

A machine is only as strong as its weakest link. Ask for a bill of materials for the key components. Are they using globally recognized, reputable brands for critical parts?

- Hydraulics: Parker, Bosch Rexroth, Eaton

- Electronics/PLCs: Siemens, Schneider Electric, Allen-Bradley

- Motors/Gearboxes: SEW-Eurodrive, Nord

Using quality components is not about brand-name snobbery. It is about proven reliability and, just as importantly, the global availability of spare parts. If a motor from a top-tier brand fails, you can likely source a replacement locally in Mexico City or Monterrey. If it's a no-name brand, you are completely dependent on the original supplier. This is a critical factor in mitigating the risk of aging equipment, a challenge you are already facing.

My Insights: Why the 'Cheapest' Upender Is Often the Most Expensive

I can hear the conversation now. Your finance department has analyzed the quotes and is pushing for the lowest bid. On paper, it looks like a clear, easy win for the quarterly budget. It saves capital upfront, and it's the "fiscally responsible" choice. But you and I, as people who have lived on the factory floor, know the truth. We know about the hidden costs that never appear on a purchase order: the lower efficiency that bleeds money every single day, the frequent breakdowns that halt production, the higher energy consumption that inflates utility bills, and the ever-present safety risks.

The initial savings from a cheap machine are a mirage. They are often completely wiped out within the first year of operation by these hidden costs. As someone who has built a successful factory from the ground up, I want to share my core philosophy on making smart, long-term investments. It all comes down to understanding the Total Cost of Ownership (TCO), a principle that will protect you from short-term thinking and guide you to a decision your future self will thank you for.

Diving Deeper into My Personal Philosophy

My journey in this industry began not in an office, but as an engineer on the factory floor. I saw firsthand how a single piece of unreliable equipment could sabotage production schedules, destroy team morale, and create unsafe working conditions. The frustration was immense. When I took the leap and founded SHJLPACK, I made a promise to myself: I would only design and build machines that I would be proud to use in my own factory. This is not just a business for me; it is my life's work. This path has granted me financial independence, and it has been built on helping my clients—people just like you—grow their businesses by making smart equipment choices. Now, my mission is to give back by sharing the knowledge that brought me success.

Thinking in Total Cost of Ownership (TCO)

The purchase price is just the tip of the iceberg. The real cost of a machine unfolds over its 15-20 year lifespan.

- Purchase Price: This is the visible cost, but it's often only 20-30% of the TCO.

- Installation & Commissioning: A low-cost supplier often cuts corners here. A difficult installation with poor support can lead to days of extra downtime and labor costs before the machine even starts running.

- Energy Costs: This is a major challenge for you. A well-designed, efficient hydraulic system or a modern electromechanical drive can consume significantly less energy than a poorly designed one. A 10% reduction in energy use on a machine that runs daily can add up to thousands of dollars in savings each year, directly addressing your goal to lower unit energy consumption.

- Maintenance & Parts: A cheap machine uses cheaper components that fail more often. What is the cost of replacement parts? How frequently will you need to service it? A machine that requires constant attention from your maintenance team is stealing resources from other critical areas.

- The Cost of Downtime: As we've discussed, this is the killer. A machine that is 30% more expensive upfront but delivers 99% uptime is infinitely cheaper than a bargain machine with 90% uptime. The math is simple and brutal.

- Safety & Compliance: An accident can have unlimited costs. A quality manufacturer builds machines that meet or exceed the latest safety standards, protecting your people and your business from catastrophic liability.

A vendor sells you a product. A partner invests in your success. They work with you on a solution that fits your entire operation. They help you think about integration, workflow, and even how to incorporate the machine into your future digitalization plans by adding sensors for data collection and predictive maintenance. This is the core mission of SHJLPACK. We are a knowledge-sharing platform dedicated to being that partner. Your success is our success.

Conclusion

Choosing the right mold upender is a strategic decision. Focus on technical fit, responsive local support, and total cost of ownership to ensure safety, reliability, and excellent long-term value.