Buying heavy equipment for a steel mill is a high-stakes decision. I know this because I've been on both sides of the table. I started as an engineer on the factory floor, and later, I built my own company, SHJLPACK, manufacturing these machines. When you're considering a mold tilter for your operations in Brazil, a mistake isn't just a financial loss. It's a potential safety hazard and a production bottleneck that can halt your entire line. The pressure to get it right is immense, and the details can be overwhelming.

Before buying a mold tilter, Brazilian procurement teams must verify three critical areas. First is strict compliance with Brazil's NR-12 safety standard, which dictates mandatory mechanical and electrical safety features. Second is a thorough analysis of technical specifications like load capacity and drive system to match your specific operational needs. Third is confirming the supplier has robust, in-country after-sales support, including local technicians and spare parts availability.

I've seen many companies focus only on the initial price tag. This is a common mistake. A truly successful purchase goes much deeper. It involves understanding the unique regulatory landscape in Brazil, scrutinizing the engineering behind the machine, and ensuring you have a reliable partner for the long haul. In this article, I will share my hands-on experience to guide you through these crucial considerations. Let's make sure your next investment is a lasting success for your plant.

How Does Brazil's NR-12 Standard Impact Mold Tilter Design?

Your team found a mold tilter that looks perfect on paper. The price is competitive, and the delivery time is short. But there's a nagging question: Is it compliant with Brazilian law? Ignoring Brazil's NR-12 safety standard is a risk you cannot afford to take. I have seen operations shut down by regulators and companies face heavy fines, all because their new equipment didn't meet these specific safety rules. It turns a promising investment into a serious liability overnight.

Brazil's NR-12 standard directly impacts mold tilter design by mandating specific safety components and documentation. This includes dual-channel safety circuits, emergency stop buttons that are easily accessible, physical guarding to prevent access to moving parts, and hydraulic systems with anti-burst valves. All documentation, including the risk assessment and user manuals, must also be provided in Brazilian Portuguese.

NR-12 is not just a suggestion; it is the law governing machine safety in Brazil. It is one of the most comprehensive safety regulations in the world. As a manufacturer, we at SHJLPACK treat it with the utmost seriousness. It's not about adding a few extra buttons or guards. It's about designing safety into the core of the machine from the very first blueprint. Understanding these requirements is the first and most important step for any Brazilian procurement team.

Deep Dive: Deconstructing NR-12 for Mold Tilters

NR-12 compliance is not a simple checklist item. It's a design philosophy. For a heavy-duty machine like a mold tilter, which handles immense weight and force, these regulations are what separate a safe workhorse from a potential disaster. Let's break down the key areas that your procurement team must verify.

Mechanical Safety Requirements

The most visible part of NR-12 compliance is physical guarding. The standard is very clear: any area where an operator could be crushed, sheared, or drawn in must be protected. For a mold tilter, this means fixed guards around the base and drive mechanism. It also often requires perimeter fencing with safety-interlocked gates. If an operator opens the gate while the machine is running, the power must be cut immediately. The material and construction of these guards are also specified to withstand potential impacts. You should ask a potential supplier for detailed drawings of their guarding solution.

Electrical and Control System Safety

This is where many suppliers fall short. A standard control system is not enough. NR-12 requires a certified safety control system. This means using safety PLCs or safety relays that constantly monitor the safety devices.

- Emergency Stops: They must be red on a yellow background, easily accessible from all operator positions, and must be force-guided, meaning they physically break the circuit.

- Two-Hand Controls: For any action that requires an operator to be near the machine, two-hand controls are often necessary. This ensures the operator's hands are safely occupied and away from moving parts during operation.

- Redundancy: Critical safety circuits must be dual-channel. This means if one part of the circuit fails, the backup channel ensures the machine still enters a safe state.

Hydraulic and Pneumatic System Safety

If your tilter is hydraulic, NR-12 has specific rules. All hydraulic hoses must be rated for the pressure and protected against abrasion. More importantly, the system needs protection against hose bursts. This is usually achieved with pilot-operated check valves or hose burst valves installed directly on the cylinders. These valves automatically lock the cylinder in place if they detect a sudden loss of pressure, preventing the load from crashing down.

Here is a simple table to compare a compliant and non-compliant machine:

| Feature | Non-Compliant Tilter | NR-12 Compliant Tilter |

|---|---|---|

| Guarding | No guards or simple, removable panels. | Fixed guards, interlocked access gates. |

| E-Stop | Single, standard emergency stop button. | Multiple, force-guided emergency stop buttons. |

| Control System | Standard PLC. | Safety PLC or certified safety relays. |

| Hydraulics | No protection against hose failure. | Hose burst valves on all cylinders. |

| Documentation | Manual in English or Chinese only. | Full technical file in Portuguese, including risk analysis. |

Finally, the documentation is non-negotiable. The supplier must provide a complete "technical file" in Brazilian Portuguese. This includes detailed electrical and hydraulic schematics, a comprehensive risk assessment (Análise de Risco), and a user manual. Without this paperwork, you cannot legally operate the machine in Brazil.

What Are the Key Technical Specifications to Scrutinize for a Mold Tilter?

You've confirmed your potential supplier understands NR-12. Now, you must focus on the machine's performance. A common problem I see is a mismatch between the machine's capabilities and the plant's actual needs. A procurement team might buy a 50-ton tilter when they really need a 60-ton capacity for future, heavier molds. This leads to overloading, premature wear, and eventually, failure. Or they might choose a slow tilting speed to save costs, only to find it creates a bottleneck in their mold maintenance workflow.

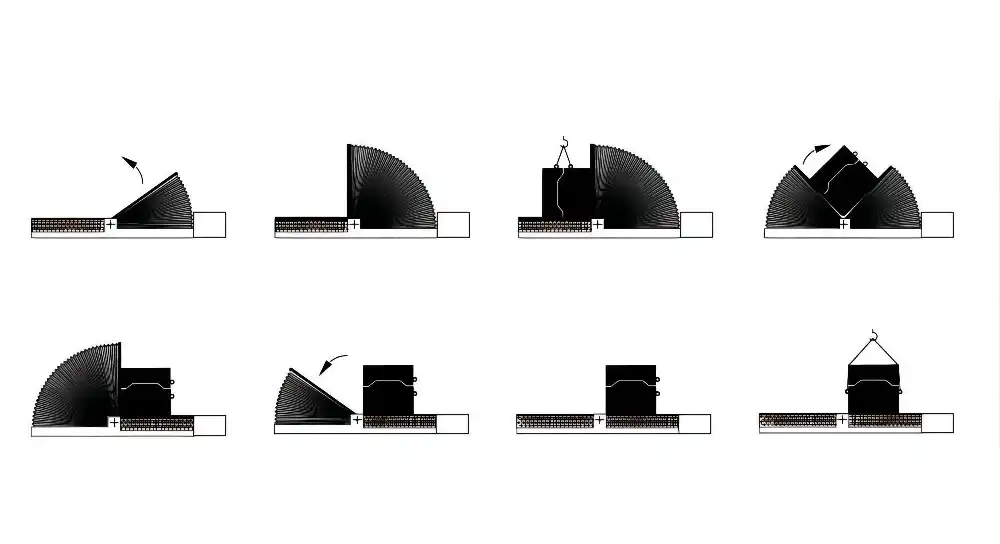

The most critical technical specifications to scrutinize for a mold tilter are its rated load capacity, the platform dimensions, the tilting angle and speed, and the type of drive system. The load capacity must include a significant safety factor above your heaviest mold. The platform must be large enough to support your biggest mold footprint securely. The tilting speed must match your operational tempo, and the choice between a hydraulic or electromechanical drive system will define the machine's maintenance needs and precision.

These specifications are not just numbers on a data sheet. They are the core elements that determine if the machine will be a valuable asset or a constant headache. I always tell my clients to think five years ahead. Your production needs will change. Your molds might get bigger. Buying a machine that can handle your future needs is one of the smartest investments you can make. Let’s look at these technical details more closely.

Deep Dive: Matching the Machine to Your Molds and Workflow

Choosing the right mold tilter is an engineering decision, not just a purchasing one. The details define the machine's longevity, safety, and efficiency. As an engineer, I focus on the fundamentals of the design.

Load Capacity and Structural Integrity

The stated capacity is the most important number. But you must ask the supplier: "What is the safety factor?" A quality machine should have a structural design safety factor of at least 1.5:1, meaning it can structurally withstand 1.5 times its rated load. Also, consider the difference between a static and dynamic load. The forces on the machine are much higher when it is starting or stopping the tilting motion. The drive system and structure must be designed for these dynamic forces. Ask to see the Finite Element Analysis (FEA) reports for the main frame. A serious manufacturer will have this data and be happy to share it. It proves they have digitally simulated the stresses on the machine structure.

Drive System: Hydraulic vs. Electromechanical

This is a fundamental choice that impacts performance, maintenance, and cost. There is no single "best" answer; it depends on your priorities.

| Aspect | Hydraulic System | Electromechanical System |

|---|---|---|

| Power | Very high lifting capacity. Ideal for extremely heavy molds (>100 tons). | Good for low to medium loads. Can be less cost-effective for very high capacities. |

| Speed | Generally faster tilting speeds are possible and easier to control. | Can be very precise, but high speed often requires a very large motor and gearbox. |

| Control | Good, smooth control with proportional valves. | Excellent precision and repeatability, ideal for integration with robots. |

| Maintenance | Requires regular checks for leaks, oil level, and filter changes. Potential for oil spills. | Requires gearbox lubrication and motor checks. Generally cleaner. |

| Footprint | Requires a separate hydraulic power unit, taking up more floor space. | The drive is integrated into the machine base, usually more compact. |

| Cost | Often lower initial cost for high-capacity machines. | Can have a higher initial cost, but potentially lower long-term energy costs. |

I've built both types. For most heavy-duty steel mill applications, hydraulic systems offer a robust and cost-effective solution. But for high-tech environments requiring extreme precision, an electromechanical system might be better.

Platform and Clamping

The platform size must be larger than the footprint of your largest mold. The mold should sit comfortably in the center, not on the edges. The platform surface can be flat steel or covered with wood or polyurethane pads to protect the mold. More importantly, how is the mold secured? Simple gravity is not enough. You need a reliable clamping system. This could be manual clamps, but for efficiency and safety, hydraulic or pneumatic clamps are far superior. These clamps should be interlocked with the tilting control. The machine should not be able to tilt unless the clamps are confirmed to be engaged. This simple interlock prevents catastrophic accidents.

Why is Local After-Sales Support a Non-Negotiable in Brazil?

You have bought a technically superior, NR-12 compliant machine. It is installed and running perfectly. But six months later, a critical hydraulic valve fails. Your machine is down. Your entire mold maintenance schedule is disrupted. You call the supplier, who is on the other side of the world. They are helpful, but the replacement part has to be shipped internationally. It gets stuck in Brazilian customs for weeks. The cost of this downtime quickly surpasses any savings you made on the initial purchase.

Local after-sales support in Brazil is non-negotiable because it is the only way to guarantee maximum uptime. The complexities of Brazilian import logistics and taxes mean that relying on international spare part shipments is slow and expensive. A supplier with a local presence can provide fast on-site service from Portuguese-speaking technicians and can maintain a local stock of critical spare parts, reducing downtime from weeks to hours.

I learned this lesson early in my career. A machine is only as good as the support behind it. This is why at SHJLPACK, we have worked hard to build partnerships and service networks in key markets like Brazil. A machine that runs 99% of the time with local support is infinitely more valuable than a machine that runs 100% of the time but has no support when it eventually fails. And every machine will eventually need maintenance. For a procurement team, evaluating a supplier's support structure is just as important as evaluating their machine.

Deep Dive: The True Cost of Downtime in Brazil

In the steel industry, uptime is everything. When a key piece of equipment like a mold tilter goes down, the ripple effects are enormous. It’s not just about one machine being idle. It’s about the entire production chain it supports.

The Reality of Brazilian Logistics

Anyone who has done business in Brazil understands that the import process can be challenging. It's not just about shipping time. The "Custo Brasil" (Brazil Cost) includes high import duties, taxes like IPI and ICMS, and bureaucratic hurdles at customs (Receita Federal). A simple €500 valve from Europe can end up costing you €1,500 and take six weeks to arrive. A supplier without a local entity or warehouse cannot protect you from this reality. A supplier with a local presence has already imported the parts and paid the taxes. The part is on a shelf in São Paulo, not in a warehouse in Shanghai or Hamburg. This is the single biggest advantage of local support.

What Does "Good" Local Support Look Like?

"Local support" is an easy phrase to say, but what does it mean in practice? Here are the specific things you should demand from a supplier.

- Local Technicians: Are their technicians based in Brazil? Are they direct employees or third-party contractors? Can they be on-site at your plant within 48 hours? Do they speak fluent Portuguese?

- Local Spare Parts Inventory: Ask for a list of the spare parts they stock in Brazil. This should include critical wear items like seals, filters, sensors, and valves. For larger components like motors or pumps, what is their strategy? Do they have a partnership with a local distributor like Siemens Brazil or Parker Hannifin Brazil?

- Training and Documentation: Does the support include training your own maintenance team? Good training empowers your team to handle first-level troubleshooting, reducing the need to call for service. Is all the service and maintenance documentation available in Portuguese?

- Remote Diagnostics: Can the supplier's engineers remotely access the machine's PLC to diagnose problems? This can often solve issues without needing a site visit, saving valuable time.

Here's how to structure your evaluation:

| Support Level | Poor Supplier | Good Supplier | Excellent Supplier (Strategic Partner) |

|---|---|---|---|

| Technicians | Based overseas. | Third-party contractor in Brazil. | Direct-employee technicians based in Brazil. |

| Spare Parts | All parts shipped from overseas. | Small stock of minor parts in Brazil. | Comprehensive local stock of critical components. |

| Response Time | Weeks. | Days. | Guaranteed response time in a Service Level Agreement (SLA). |

| Language | English/Chinese only. | Portuguese-speaking sales, English tech support. | Full support in Portuguese. |

| Training | Manuals only. | On-site training at installation. | Ongoing training for your team + remote diagnostic support. |

A few years ago, a client in Minas Gerais bought a tilter from another company based purely on price. When a gearbox failed, they discovered the supplier had no presence in Brazil. It took them three months to get the replacement. After that experience, they came to us for their next machine. They told me, "Vincent, the peace of mind of knowing you have a team we can call is worth more than any discount."

How Can a Mold Tilter Integrate with Our Digital Transformation Goals?

Your steel mill is on a journey toward Industry 4.0. You are implementing a Manufacturing Execution System (MES), deploying IoT sensors, and using data to make smarter decisions. In this context, a new machine can't be a "dumb" piece of iron. It must be a connected, intelligent asset that contributes data to your digital ecosystem. Many procurement teams still view a mold tilter as a simple, standalone machine. This is a missed opportunity. A modern tilter can be a valuable source of data that helps you optimize maintenance and improve safety.

A mold tilter integrates with digital transformation goals by ensuring its control system (PLC) can communicate with the plant's MES or SCADA systems. This is achieved using standard industrial protocols like PROFINET, EtherNet/IP, or OPC UA. This connection allows for the real-time monitoring of machine status, cycle counts, fault codes, and sensor data, enabling predictive maintenance and full production visibility.

When you think like a CEO or a plant manager, like my client Javier Morales, you are always looking for ways to improve efficiency and lower costs. Data is the key to unlocking those improvements. A connected mold tilter doesn't just turn molds; it provides the data you need to schedule maintenance for those molds more effectively. It tells you when it's operating, when it's idle, and when it needs attention. It becomes an active participant in your smart factory, not just a passive piece of equipment.

Deep Dive: Unlocking the Data from Your Mold Tilter

Integrating a mold tilter into your digital factory is not science fiction; it's a practical step that delivers tangible benefits. The key is ensuring the machine is "born digital" – designed from the start with connectivity in mind.

The Communication Backbone: PLC and Protocols

The brain of the mold tilter is its Programmable Logic Controller (PLC). Your first question to a supplier should be: "What brand of PLC do you use, and what communication protocols does it support?" In Brazil, brands like Siemens, Rockwell Automation (Allen-Bradley), and Schneider Electric have strong local support. Choosing a machine with one of these PLCs makes integration much easier. The machine must be able to speak the same language as your factory network. The most common languages (protocols) are:

- PROFINET: The standard for Siemens-based automation.

- EtherNet/IP: The standard for Rockwell-based automation.

- OPC UA (Unified Architecture): A universal, platform-independent protocol that is becoming the gold standard for Industry 4.0. It's secure and allows for rich data exchange.

Insisting on one of these protocols ensures a plug-and-play connection to your existing systems.

Data Points That Drive Value

What data can a "smart" tilter provide? And how does that data help you achieve goals like increasing uptime or reducing costs?

| Data Point from Tilter | Benefit / Actionable Insight |

|---|---|

| Cycle Count | Tracks how many times the tilter has operated. This can be linked to the specific mold being serviced to precisely track the mold's usage and schedule its maintenance based on actual use, not just time. |

| Motor Current / Hydraulic Pressure | A gradual increase in motor current or hydraulic pressure can indicate mechanical wear or friction. This is a classic indicator for predictive maintenance, allowing you to schedule a repair before a failure occurs. |

| Fault Codes | Instead of just a red light on the machine, a detailed fault code is sent to the MES and to the maintenance team's mobile devices. This allows for faster diagnosis and repair. |

| Operating Hours | Tracks total run time. This is essential for scheduling preventive maintenance tasks like lubrication or filter changes. |

| Clamp Status | The MES can verify that the mold is securely clamped before allowing the next step in an automated workflow to proceed, improving safety and process integrity. |

Beyond Monitoring: Control and Automation

Integration isn't just about listening to the machine; it's also about telling it what to do. A connected mold tilter can receive commands from your MES. For example, the MES could automatically select the correct tilting program based on the mold ID, which is read by a barcode scanner. This level of automation reduces the chance of human error, improves consistency, and speeds up the entire mold handling process. It turns the mold bay from a manual operation into a streamlined, data-driven part of your production line. This is the essence of a smart factory.

Conclusion

Buying a mold tilter in Brazil requires looking beyond the price. Focus on NR-12 compliance, precise technical specs, strong local support, and digital integration. This ensures a safe, efficient, and future-proof investment.