Running a steel mill is a constant battle against costs, downtime, and market pressures. You work hard to produce high-quality steel coils, but the final step—packaging—is often a source of frustration. An old, unreliable packaging line can cause endless bottlenecks, risk worker safety, and damage your products before they even leave the factory. These delays and quality issues can hurt your reputation and your bottom line. I understand this because I've lived it. The solution isn't just a new machine; it's a completely new approach to packaging. It's about a total solution that delivers safety, speed, and unwavering reliability, just like the systems we have successfully implemented for our partners in Greek steel mills.

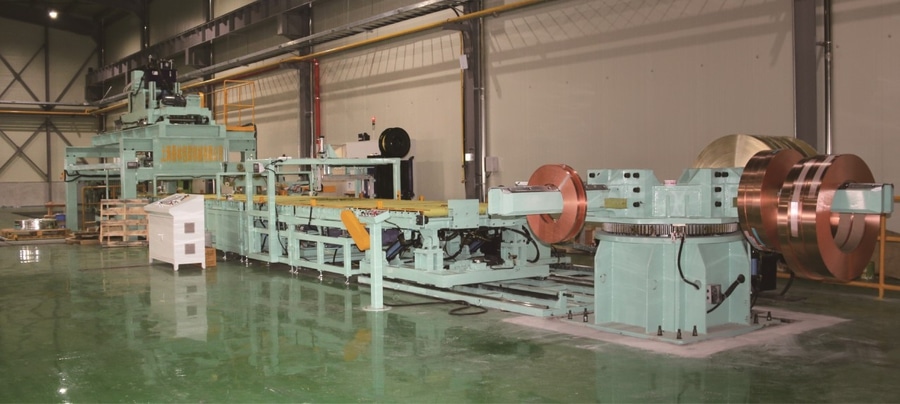

A coil packaging line for a modern steel mill, like those in Greece, is made safe, fast, and reliable by integrating robust mechanical engineering with smart automation. This involves using heavy-duty, high-quality components to prevent mechanical failures, incorporating advanced safety features like light curtains and physical guarding to protect operators, and implementing a synchronized PLC control system. This system ensures every step, from coil loading to final strapping, works together seamlessly for maximum speed and consistent, high-quality wrapping.

This might sound like a complex engineering promise. But it is built on practical, real-world experience. I started my career on the factory floor, so I know that what matters most is equipment that works every single day without causing problems. A packaging line is the last touchpoint you have with your product. It has to be perfect. Let's break down how we turn these principles into a reality on the factory floor, answering the critical questions that steel mill owners like you ask me every day.

How Can a Modern Packaging Line Guarantee Reliability and Safety?

You see an aging packaging line on your floor and you see risk. It’s a machine that has served its time, but now every unusual noise makes you think about potential breakdowns and, worse, safety incidents. An unexpected failure can bring your entire dispatch operation to a halt, and a safety issue is a nightmare that no owner ever wants to face. I know this feeling well. The truth is, modern packaging lines are designed with a completely different philosophy. They are built from the ground up to eliminate these risks by making reliability and safety the foundation of the entire design.

A modern packaging line guarantees reliability and safety through a combination of superior construction, certified safety technology, and intelligent design. Reliability comes from using heavy-duty steel frames and internationally recognized components from brands like Siemens or Schneider. Safety is ensured with multiple layers of protection, including fully enclosed moving parts, electronic safety gates, light curtains that stop the machine if an operator enters a dangerous area, and easily accessible emergency stops.

Dive Deeper: The Engineering Behind Dependability

When I talk about reliability, I am not just talking about a machine that turns on. I am talking about a machine that performs consistently for years, under the heavy demands of a steel mill. This starts with the very bones of the line.

Building for Unstoppable Performance

The foundation of a reliable line is its physical construction. Old machines often used lighter materials or had designs that created stress points. A modern line is different. We use thick, reinforced steel for the frame and conveyors, designed to handle the immense weight and impact of steel coils day after day. All welds are inspected, and the structure is built to absorb vibrations, which reduces wear and tear on all components.

But the frame is just the start. The real reliability comes from the parts that do the work. I learned early in my career that saving a little money on a critical component like a motor or a sensor is a bad decision. It always costs more in the long run through downtime and repairs. That is why we build our lines using components from globally trusted brands. Think of PLC systems from Siemens, bearings from SKF, and motors from SEW. These parts are known for their long life and consistent performance. This means your maintenance team isn't constantly fighting fires, and you can trust the line to be ready when you need it.

A Zero-Compromise Approach to Safety

In a steel mill, safety is not a feature; it is a requirement. A modern packaging line must protect your people above all else. We design our systems with layers of safety.

| Safety Feature | How It Protects Your Team |

|---|---|

| Physical Guarding | All moving parts, like the wrapping ring and strapping heads, are enclosed in heavy-duty steel mesh fences. This physically prevents anyone from accidentally touching a dangerous part of the machine. |

| Safety Interlock Gates | Access doors to the machinery area are fitted with electronic interlocks. If a door is opened while the machine is running, the system immediately stops in a safe state. It cannot be restarted until the gate is closed and a reset command is given. |

| Light Curtains | At the entry and exit points of the line, we install light curtains. These are invisible beams of light. If a person or forklift breaks the beam while the machine is in an automatic cycle, it will instantly stop. |

| Ergonomic Design | We design the operator stations to be comfortable and reduce physical strain. Controls are placed at a comfortable height, and manual tasks are minimized or eliminated, reducing the risk of repetitive strain injuries. |

These systems work together to create a safe environment. It gives you, as the owner, peace of mind. And it shows your team that you value their well-being. This is how we build trust, both in the machine and in the partnership.

What Makes a Coil Packaging Line Fast Without Sacrificing Quality?

Every steel mill owner wants to increase throughput. You want to get more coils wrapped and shipped every single day. The old way to do this was just to speed up the motors. But this often leads to problems: sloppy wrapping, loose straps, and damaged coil edges. This kind of "speed" actually costs you money in customer complaints and returned products. True speed in a packaging line doesn't come from just being fast; it comes from being smart and efficient. It is about eliminating wasted time and motion, so the entire process flows smoothly from start to finish.

A coil packaging line achieves high speed without sacrificing quality by synchronizing every step of the process through an intelligent PLC control system. This means the coil is moved, centered, strapped, and wrapped in a continuous, optimized flow. High-speed wrapping rings, automatic strap feeding, and simultaneous operations, like weighing while labeling, cut down the total cycle time for each coil. The quality is maintained because the automation ensures every coil is packaged to the exact same high standard, every time.

Dive Deeper: The Science of Efficient Flow

Achieving speed is a science. It's about analyzing every single second of the packaging cycle and finding ways to make it more efficient. This is where my engineering background becomes so important. We don't just sell machines; we design workflows.

The Anatomy of a High-Speed Workflow

A fast packaging line is like a well-rehearsed orchestra. Every instrument plays its part at exactly the right moment. Here is how we choreograph the movement of a steel coil for maximum speed:

- Smart Coil Entry: As one coil is being finished, the next coil is already being loaded onto the entry conveyor. Sensors detect its presence and automatically move it into a waiting position. There is no idle time waiting for the operator to load the next coil.

- Synchronized Movement: The PLC controller acts as the conductor. It knows the exact position of every coil on the line. As soon as the wrapping station is free, the waiting coil is instantly and smoothly moved into place. The conveyors speed up and slow down precisely to ensure gentle handling but quick transfer.

- Parallel Processing: We look for opportunities to do two things at once. For example, the coil can be automatically weighed by load cells integrated into the conveyor while it is moving to the labeling station. The strapping can happen at the same time the wrapping material is being prepared for the next cycle. This eliminates sequential delays.

- High-Performance Wrapping Technology: The wrapping ring itself is a key component for speed. Modern rings are lighter, stronger, and driven by powerful, precise motors. They can apply stretch film or VCI paper at very high speeds while maintaining consistent tension, which is crucial for protecting the coil. The film or paper roll can also be changed quickly with quick-change carriages, minimizing downtime.

Automation That Drives Profitability

Automation is the engine that makes this high-speed workflow possible. It removes the variability and delays associated with manual operations. For a steel mill owner like Javier, this directly addresses the goal of increasing capacity utilization. When the packaging line runs smoothly and quickly, it doesn't become a bottleneck. This allows your production lines to run at their full potential.

This level of automation also reduces the need for manual labor around the line. This not only lowers your operating costs but also moves your skilled workers away from repetitive tasks and into more valuable roles, like quality control or maintenance planning. A fast, automated line pays for itself through increased throughput, lower labor costs, and consistent, high-quality packaging that keeps your customers happy.

How Do We Design a Packaging Line as a Strategic Asset, Not Just a Machine?

When you look at a proposal for new equipment, you see a large capital investment. It is easy to view it as just another expense. But some investments are different. A simple, standalone machine might solve a problem today, but it can become obsolete tomorrow. A true strategic asset is an investment that grows with your business, provides valuable data, and helps you become more competitive in the long run. It should not just be a cost center; it should be a profit driver.

We design a packaging line as a strategic asset by building it on a foundation of modularity, data connectivity, and a commitment to a long-term partnership. Modularity means the line can be easily upgraded or adapted as your needs change. Data connectivity allows the line to integrate with your factory's MES and ERP systems, providing critical data for decision-making. The partnership ensures you have our full support for maintenance, optimization, and future planning, turning the machine into a tool for continuous improvement.

Dive Deeper: Building Your Future-Proof Factory

Thinking of a packaging line as a strategic asset is a shift in mindset. It’s about looking beyond the initial purchase price and considering the Total Cost of Ownership (TCO) and the Return on Investment (ROI) over the life of the equipment. This is exactly the kind of analysis that a forward-thinking owner like Javier performs. Here is how we deliver on that vision.

Modularity: Designed for Tomorrow's Needs

The steel industry is not static. Your customers' requirements might change. You might want to add a new type of packaging material or a more advanced labeling system in a few years. A traditional, monolithic machine would require a complete replacement. A modular design is different.

We design our packaging lines in sections, or modules. For example, the strapping unit, the wrapping unit, and the labeling unit are all individual modules controlled by a central PLC. If you decide in three years that you need to add an automated stacking system, we can design and integrate that new module into your existing line. The control system is already built to be expandable. This approach protects your initial investment and allows your packaging capability to evolve with your business strategy.

Data is the New Steel: IoT and MES Integration

This is where a packaging line truly becomes a strategic tool. This directly addresses the goal of digital transformation. We embed IoT (Internet of Things) sensors throughout the line. These sensors can monitor everything:

- Motor temperature and vibration: This data is used for predictive maintenance. The system can alert you that a motor needs service before it fails, allowing you to schedule maintenance during planned downtime. This is key to achieving 95% equipment uptime.

- Material Consumption: The system tracks exactly how much stretch film and strapping is used for each coil. This data can be used to optimize material usage and control costs, helping you reach that goal of an 8% reduction in operating costs.

- Overall Equipment Effectiveness (OEE): The line connects directly to your Manufacturing Execution System (MES). It provides real-time data on availability, performance, and quality. You can see your true throughput on a dashboard in your office.

This data allows you to manage your packaging operation with facts, not guesses. You can identify inefficiencies, track performance against your goals, and make informed decisions to improve your profitability.

| Traditional Machine | Strategic Asset |

|---|---|

| Fixed functionality. | Modular and upgradeable. |

| Operates in isolation. | Integrates with factory MES/ERP. |

| Provides no data. | Generates actionable data (OEE, costs). |

| Reactive maintenance (fix when broken). | Predictive maintenance (fix before broken). |

| A simple supplier transaction. | A long-term technology partnership. |

By designing the line this way, we are not just providing a machine. We are providing a platform for growth and a key component of your smart factory vision.

Why Do I Believe a Packaging Line is More Than Just Steel and Wires?

Many companies can sell you a machine. They can show you specifications and give you a price. But after the installation, they are gone. When a problem comes up, you are left alone to figure it out. This is not a partnership. It is just a transaction. I believe this is the wrong way to do business, and my belief comes from my own personal journey in this industry.

I believe a packaging line is more than steel and wires because it represents the final promise you make to your customer. It is the handshake that guarantees the quality product you manufactured will arrive safely. From my own experience building a factory from the ground up, I learned that the right equipment partner is not just a supplier; they are essential for your growth, your peace of mind, and your success. That machine is a symbol of trust.

Dive Deeper: My Journey and My Promise

From Engineer to Factory Owner

Before I started SHJLPACK, I was an engineer. And after that, I started my own factory, just like many of you. I remember the early days clearly. I saved every penny to buy the equipment I needed. I once bought a packaging machine from a supplier who gave me the lowest price. I thought I had gotten a good deal.

A few months later, we were about to ship a huge order to a very important new customer. It was a contract that would have helped my young company grow. In the middle of the night, the main drive on that cheap packaging machine failed. We had no spare parts. I tried to call the supplier, but nobody answered. My team and I worked all night, trying to wrap the coils by hand. We failed. The shipment was late, the packaging was poor, and I lost that customer. I almost lost my business that day.

What I Learned About Partnership

That painful experience taught me the most valuable lesson of my career: a machine is only as good as the company that stands behind it. The price you pay upfront is only a small part of the story. The true value is in the support, the expertise, and the reliability of the partner you choose.

When I started SHJLPACK, I made a promise to myself. I would never let one of my clients go through what I went through. That is why our mission is to be a "Total Solution." It means we are with you from the very beginning, helping you choose the right design. It means we are there during installation and training, making sure your team is confident. And it means we are still there years later, providing support, spare parts, and advice.

I achieved my own financial independence because of the opportunities this industry gave me. Now, my goal is to give back. I want to share what I've learned to help you succeed. When we sell you a packaging line, we are not just delivering steel and wires. We are delivering a promise of reliability, a commitment to your success, and a partnership you can count on. That, to me, is the real meaning of a total solution.

Conclusion

A great coil packaging line is an investment in safety, speed, and your reputation. At SHJLPACK, we build reliable solutions designed for your success.