Running a steel mill in Argentina is tough. I know. You face constant pressure from fluctuating energy costs, global market shifts, and the high price of every single breakdown. Your steel coils are the final product of a long, expensive process. But the last step, handling and packaging, is often where profits are lost. Manual handling leads to dents, scratches, and damaged edges. It's slow. It's inconsistent. And every damaged coil that gets rejected by a customer is a direct hit to your bottom line. This isn't just a small problem; it's a constant drain on resources and a source of major stress. You work hard to produce quality steel, only to see it damaged moments before it leaves your plant. There has to be a better way.

The most effective way to lower coil damage and increase throughput is to implement automated packaging and handling solutions. Systems like automated wrappers, integrated conveyors, and robotic handling minimize manual contact, ensuring gentle and precise movements. This consistency drastically reduces damage rates. At the same time, these systems operate at a continuous, optimized pace, eliminating bottlenecks and significantly boosting the number of coils you can process and ship per hour.

I’ve spent my entire career in the packing machine industry. I started on the factory floor, just like many of your team members. I learned firsthand how a small mistake in handling could ruin a perfectly good product. Later, when I built my own factory, I faced the same challenges you do: how to improve efficiency, cut costs, and deliver a perfect product every time. I’m not just a machine seller; I'm an engineer who has solved these exact problems. Today, I want to share what I've learned, not just as a supplier, but as a partner. Let's break down how specific automation technologies can solve these challenges for the steel sector in Argentina.

How Can Automated Wrapping Lines Directly Cut Operational Costs?

You see the big, obvious costs every day: electricity, raw materials, labor. But what about the hidden costs that slowly eat away at your profit margins? Think about the wrapping film or paper used in your packaging line. With manual or semi-automatic methods, operators often use more than necessary "just to be safe." This waste adds up. Then there's the labor cost for a task that is repetitive and physically demanding. Finally, consider the cost of downtime when older, less reliable equipment breaks down. These small, constant drains are frustrating because they feel uncontrollable. They make it hard to hit your goal of reducing overall operating costs.

Automated wrapping lines directly cut operational costs by optimizing three key areas. First, they use precise sensor-based controls to apply the exact amount of wrapping material needed, eliminating waste. Second, they reduce the need for manual labor in the wrapping process, freeing up skilled workers for more valuable tasks. Third, modern automated systems are built for reliability, drastically cutting downtime and associated maintenance costs.

Let's dive deeper into the real-world savings. As an engineer, I believe in numbers and clear analysis. When a client like Javier, a steel mill owner with deep operational knowledge, considers an investment, he needs to see the return on investment (ROI). It's not just about a new machine; it's about a smarter, more profitable process.

Analyzing Material Savings

The most immediate saving comes from material consumption. An automated stretch wrapper, for example, has a powered pre-stretch system. This system can stretch the film by 200-300%. This means one meter of film on the roll becomes three or four meters on the coil. Manual application achieves almost no pre-stretch. Even semi-automatic machines have less efficient systems. Modern machines also control the overlap of the wrap with incredible precision. This ensures complete protection without wasting a single centimeter of film. The same principle applies to paper wrapping. An automated system ensures the paper is applied tightly and with the perfect overlap, every time.

| Feature | Manual / Semi-Auto Wrapping | Fully Automated Wrapping | Impact on Cost |

|---|---|---|---|

| Stretch Film Usage | Low pre-stretch, high overuse | 200-300% powered pre-stretch | Reduces film cost by 50-75% |

| Material Overlap | Inconsistent, often excessive | Precise, sensor-controlled | Minimizes waste, ensures full coverage |

| Damaged Wraps | Prone to tearing, requires re-wrapping | Consistent tension, smooth application | Reduces rework and material loss |

The True Cost of Labor and Downtime

When you automate the wrapping process, you're not just saving a salary. You're reallocating a valuable human resource. Your team members are smart. They can be trained for quality control, predictive maintenance, or machine supervision—tasks that add more value than manually guiding a wrapping tool. Automation also reduces the risk of repetitive strain injuries, which leads to a safer workplace and lower insurance costs. Furthermore, new automated lines are built for endurance. I remember a client in Mexico whose old wrapping machine was down for maintenance almost one day a week. The lost production was a huge cost. After we installed a new automated line, their uptime for the packaging station went to over 98%. The machine paid for itself in less than two years from the uptime gains alone.

Energy Efficiency Gains

Modern machines are designed with energy costs in mind. They use high-efficiency motors and variable frequency drives (VFDs). A VFD ensures the motor only uses the exact amount of power needed for the task at hand, rather than running at full speed all the time. The system can also enter a low-power standby mode when no coil is present. These may seem like small things, but over 24/7 operation, they contribute significantly to your goal of lowering unit energy consumption. This is a key concern for any steel producer in Argentina facing volatile electricity prices.

What's the Real Impact of Integrated Handling on Throughput and Safety?

You have a powerful production line, but does your plant's output match its potential? Often, the biggest bottleneck isn't the main process; it's the space in between. Coils pile up, waiting for an overhead crane. Forklifts weave through busy areas, creating safety hazards and delays. A fast wrapping machine is useless if coils can't get to it and away from it efficiently. This disconnect between processes caps your throughput and keeps you from reaching that goal of 95% capacity utilization. It's a frustrating situation where your expensive production assets are being held back by inefficient logistics.

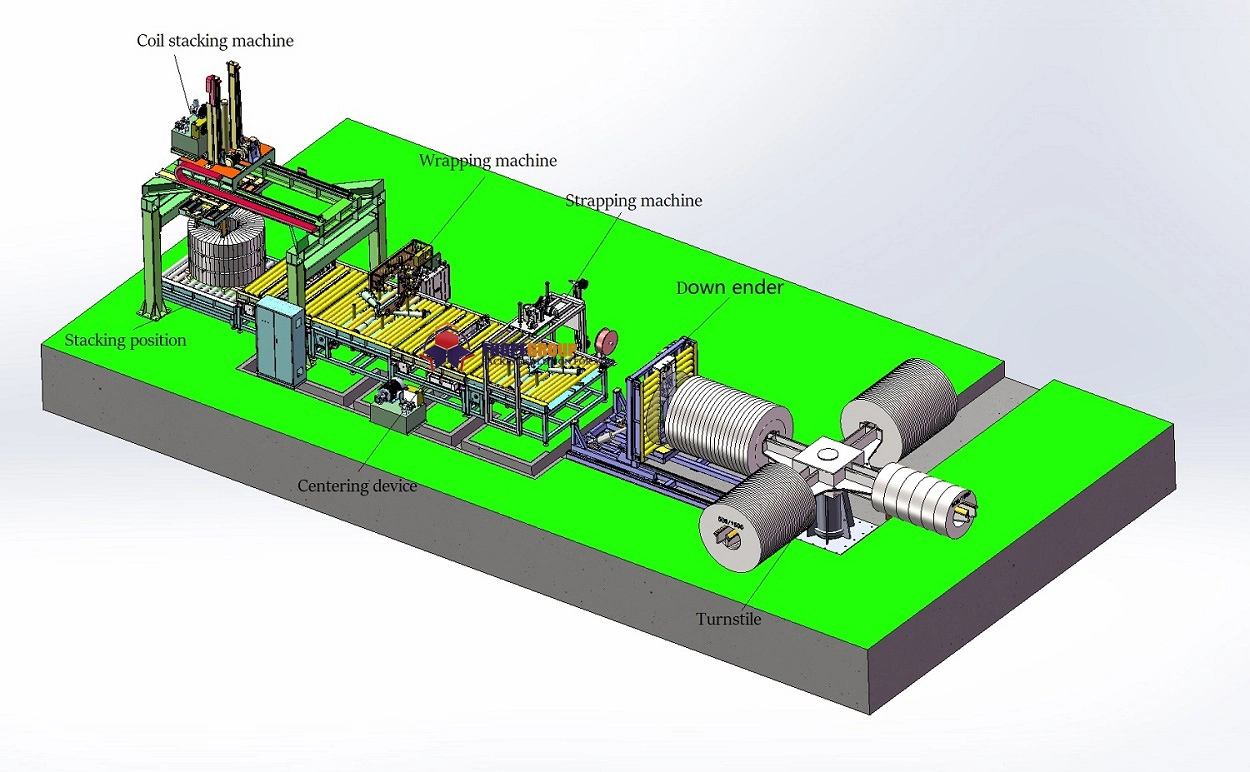

Integrated handling systems, which include equipment like coil cars, turnstiles, and powered conveyors, create a seamless and continuous flow. They eliminate the "stop-and-go" nature of manual handling. By directly connecting the end of your production line to the packaging station and then to the warehouse, these systems drastically increase throughput. They also improve safety by removing forklifts and personnel from the direct path of moving multi-ton steel coils.

Let's move beyond the general idea and look at the mechanics of it. When I visit a steel mill, I often draw a simple map of how a coil moves. Tracing this path reveals the hidden inefficiencies. Improving this path is one of the most impactful changes a mill can make.

From Bottleneck to Continuous Flow

In a traditional setup, the journey of a coil is full of stops. It comes off the recoiler, is lifted by a crane, and placed on the floor. It waits. A forklift then picks it up and drives it to the packaging area. It waits again. After wrapping, the process repeats to move it to storage. Each "wait" is a loss. An integrated system changes this completely.

A coil car can receive the coil directly from the recoiler. It then transfers it to a turnstile, which acts as a buffer and positions the coil for the next step. From the turnstile, a powered conveyor moves the coil directly into the wrapping machine. No waiting. No forklifts. After wrapping, another conveyor moves it to an automated stacking or banding station. The entire process is synchronized.

| Handling Stage | Traditional Method (Forklift/Crane) | Integrated System (Conveyors/Turnstile) | Key Benefit |

|---|---|---|---|

| Recoiler to Packaging | Crane lift -> Floor storage -> Forklift transport | Coil Car -> Conveyor/Turnstile | Eliminates waiting time, continuous flow |

| Positioning for Wrap | Manual adjustment by forklift | Automatic centering on conveyor | Faster cycle time, less damage risk |

| Packaging to Storage | Forklift transport to warehouse | Conveyor -> Automated Stacker | Reduces traffic, improves safety, faster clearing |

| Overall Cycle Time | 10-15 minutes per coil | 2-3 minutes per coil | 5x Increase in throughput potential |

A Safer Work Environment by Design

I will never forget a visit to a plant where I saw a forklift have to brake suddenly, causing its load—a 10-ton steel coil—to shift dangerously. Nobody was hurt, but it was a stark reminder of the risks. The number one priority in any plant is the safety of its people. Integrated automation is fundamentally safer because it creates predictable paths for heavy materials and separates people from those paths. Conveyors are guarded. Light curtains and safety scanners create invisible barriers that shut the system down if a person enters a dangerous area. By removing the chaotic variable of forklift traffic around the packaging line, you significantly reduce the potential for serious accidents. This isn't just a compliance issue; it's about building a culture of safety that everyone, from the CEO to the floor worker, can be proud of.

How Does Automation Prepare a Steel Mill for Digital Transformation?

The terms "Industry 4.0" and "digital transformation" can sound complicated and expensive. As a practical business owner, you might wonder if it's all just hype. You have a plant to run, and your focus is on tangible results, not buzzwords. You know you need better data to make smarter decisions, but the path to get there seems unclear. How do you connect new equipment to your existing systems? Where do you even start with deploying MES or IoT sensors? It can feel overwhelming, creating a barrier to adopting technologies that could give you a serious competitive edge.

Modern automated packaging lines are the perfect starting point for digital transformation because they are designed with data connectivity built-in. These machines are equipped with advanced PLCs and a network of sensors that capture real-time operational data. This data can be easily exported to your plant's Manufacturing Execution System (MES) or ERP, providing the critical, real-time information needed for production visualization, predictive maintenance, and overall efficiency analysis.

Let's demystify this. Think of an automated packaging line not just as a machine that wraps steel, but as a data-gathering hub. My journey as an engineer started with gears and motors. Now, a huge part of my design work involves PLCs, sensors, and data protocols. This is because my clients, like you, need more than just a machine; they need intelligence.

Data Points: The New Raw Material

A modern automated line generates a wealth of valuable data for every single coil it processes. This isn't just random information; it's actionable intelligence that can be used to drive improvements across your entire operation. This is the foundation of your goal to deploy MES and big data platforms.

- Production Data: Coils wrapped per shift, average cycle time, total uptime/downtime. This helps you accurately measure your OEE (Overall Equipment Effectiveness).

- Material Consumption: Grams of stretch film or meters of paper used per coil. This allows for precise inventory management and cost-per-coil tracking.

- Machine Status: Real-time diagnostics, fault codes, motor temperatures, sensor status. This is the key to predictive maintenance, allowing you to fix problems before they cause a breakdown.

- Product Tracking: Each coil's data can be linked to its unique ID, providing full traceability from the production line to the customer.

Integration: Making the Connection

How does this data get from the wrapping machine to your office computer? It's simpler than you might think. Modern PLCs (the machine's brain) can communicate using standard industrial protocols like PROFINET, EtherNet/IP, or OPC-UA. Your IT team or a systems integrator can easily connect the packaging line to your plant's network. The data then flows to your MES, which turns the raw numbers into easy-to-read dashboards, charts, and reports. This gives you a live, visual overview of your packaging operation, allowing you to spot trends and identify inefficiencies instantly.

| Digital Transformation Phase | Action | Technology Involved | Outcome |

|---|---|---|---|

| Phase 1: Foundational | Install an "Industry 4.0-ready" automated packaging line. | PLC, HMI, basic sensors | Collect basic production data (counts, cycle times). |

| Phase 2: Visualization | Connect the line to the plant network and an MES. | Industrial Ethernet, MES software | Real-time dashboards, OEE tracking, remote monitoring. |

| Phase 3: Optimization | Use data analytics to identify patterns. | Data analytics platforms, IoT sensors | Predictive maintenance alerts, process optimization. |

| Phase 4: Integration | Link MES data with the business-level ERP system. | ERP integration modules | Automated inventory updates, cost analysis, sales forecasting. |

This phased approach means you don't have to do everything at once. You can start with a solid, automated foundation and build your digital capabilities over time. This aligns with a pragmatic, ROI-focused strategy, ensuring each step provides measurable value. This is the path to achieving a truly smart factory.

Conclusion

Automating your coil packaging is more than an upgrade. It is a strategic investment in reducing damage, increasing throughput, cutting costs, and making your entire operation safer and smarter.