The steel market in Argentina is facing constant change. Economic shifts, new government policies, and fluctuating global demand create an environment of uncertainty. For a steel mill owner, this instability is a serious problem. You might be focused on your furnaces and rolling mills, but a hidden weakness could undermine your entire operation. An outdated coil packaging line, unable to keep up with modern demands, can become a critical bottleneck. This single point of failure can lead to shipment delays, increased labor costs, and damaged products, threatening your profitability and reputation in a market that shows no mercy.

Your coil packaging line is ready for Argentina's changing steel market if it is automated, flexible, and data-driven. A modern system can adapt to fluctuating demand, reduce operational costs, and handle diverse product specifications without creating a bottleneck. This ensures you can stay competitive and protect your profit margins, no matter how the market shifts.

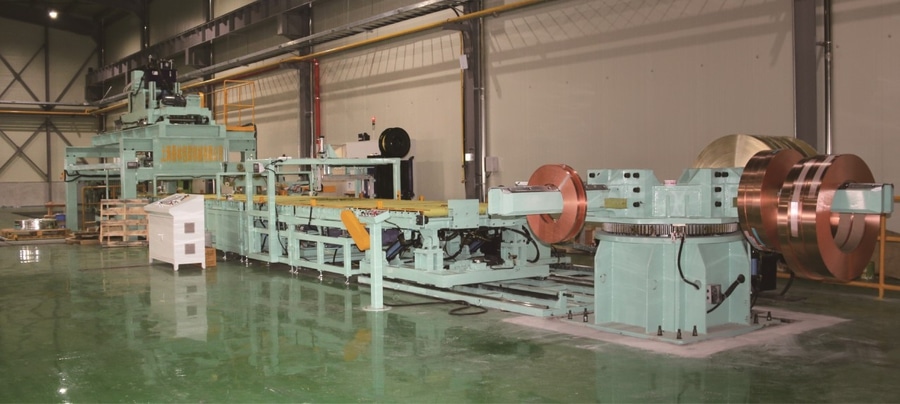

I've spent my entire career in the packing machine industry. I started as an engineer on the factory floor and eventually built my own company, SHJLPACK. I understand the pressure you're under. Every piece of equipment must justify its existence and contribute to the bottom line. A packaging line isn't just a machine at the end of your process; it's a strategic asset that can either hold you back or propel you forward. Let's look at the critical questions you should be asking to determine if your line is ready for the challenges ahead.

How Can Automation Counteract Argentina's Labor Cost Volatility?

In a market like Argentina, labor costs can be a moving target. Unpredictable wage inflation and labor availability can turn your operational budget into a guessing game. This creates a huge risk for your business. Relying heavily on manual labor for coil packaging means your efficiency, quality, and costs are tied directly to these fluctuations. One unexpected wage hike or labor shortage can disrupt your entire shipping schedule and shrink your margins. The solution is to take control of these variables. Automation offers a way out by providing predictable costs, unwavering quality, and enhanced operational safety, shielding your business from labor market instability.

Automation counteracts labor cost volatility by replacing variable manual labor expenses with a fixed, predictable capital investment. An automated coil packaging line operates 24/7 with consistent quality and minimal human intervention. This significantly reduces long-term operational costs and your dependency on a fluctuating labor market.

Dive Deeper: The Real ROI of Automation

When I talk to steel mill owners like Javier, the conversation about automation often starts with the initial cost. But the real discussion should be about the long-term return on investment (ROI). An automated packaging line is not just about reducing headcount. It’s about creating a more resilient and efficient operation. I’ve seen this firsthand. A client of mine was constantly struggling with inconsistent packaging quality, which led to customer complaints and product damage during transit. The root cause was high employee turnover and the difficulty of training new staff for a physically demanding job. By investing in an automated line, they solved these issues almost overnight.

From Variable Cost to Fixed Asset

The most significant shift is moving your packaging costs from a variable operational expense (OPEX) to a predictable capital expense (CAPEX). Manual labor costs fluctuate and almost always trend upward. An automated system has a known cost that can be depreciated over time. This makes financial planning far more accurate. It frees your business from the volatility of the labor market and allows you to forecast your costs with much greater certainty.

A Look at the Numbers

Let's break down the comparison. A manual process has many hidden costs beyond just wages. Think about recruitment, training, benefits, and the cost of human error. An automated system minimizes these. It performs the same task with the same precision every single time. This consistency is invaluable. It reduces material waste from improper wrapping and minimizes the risk of safety incidents, which carry their own significant costs.

Here’s a simple comparison to illustrate the point:

| Feature | Manual Packaging Process | Automated Packaging Line |

|---|---|---|

| Labor Cost | High and Variable (Wages, Benefits, Overtime) | Low and Fixed (Minimal operators/supervisors) |

| Consistency | Low (Depends on operator skill and fatigue) | High (Machine precision, 24/7 operation) |

| Material Waste | Moderate to High (Improper wrapping, errors) | Low (Optimized material usage) |

| Safety Risk | High (Heavy lifting, repetitive motion) | Very Low (Operators are separated from machinery) |

| Throughput | Limited by human speed and endurance | High and Consistent (Matches production speed) |

For a leader focused on long-term strategy and stability, the choice becomes clear. Automation isn't an expense; it's an investment in predictability and control.

Is Your Aging Packaging Equipment a Bottleneck for Higher Throughput?

You have invested heavily in your production capacity. Your mill is capable of producing more steel than ever before. But are you actually shipping more? If your total output feels stuck despite upstream improvements, the problem might be at the very end of your line. An old, slow packaging system cannot keep up with a modern production pace. It becomes a bottleneck, forcing your entire operation to slow down. Coils start piling up, your yard becomes congested, and promised delivery dates are missed. This not only frustrates your team but also damages your relationship with customers. A modern, high-speed packaging line is engineered to eliminate this bottleneck, unlocking your plant's true potential.

Yes, your aging packaging equipment is almost certainly a major bottleneck if you experience frequent downtime, slow cycle times, or an inability to handle the full output of your production lines. This inefficiency directly caps your plant's throughput, increases operational costs, and prevents you from reaching goals like 95% effective run time.

Dive Deeper: Identifying and Eliminating Your Bottleneck

As an engineer, I love data. And the best metric for understanding equipment performance is Overall Equipment Effectiveness (OEE). OEE measures availability, performance, and quality. An aging packaging line typically scores low in all three areas. Availability is low due to frequent mechanical breakdowns. Performance is poor because its cycle time is much slower than your mill's output. Quality suffers from inconsistent wrapping or strapping, leading to rework.

Symptoms of a Packaging Bottleneck

How do you know for sure that your packaging line is the problem? Look for these clear signs:

- Coil Congestion: You see a growing number of finished coils waiting in the bay area to be packaged.

- Upstream Stoppages: Your slitting or rolling lines have to be stopped or slowed down because the packaging line can't clear the finished product.

- Excessive Overtime: Your packaging team has to work extra hours just to keep up with a normal day's production.

- High Maintenance Costs: You are spending more and more time and money on spare parts and repairs for the packaging machine.

If you see these signs, your packaging line is holding back your entire plant's profitability.

Calculating the Cost of Inefficiency

The cost of this bottleneck is more than just maintenance bills. It's the lost revenue from the extra tons of steel you could have produced and shipped. When I work with clients, we do a simple calculation. We look at the target output of their mill and compare it to the actual output of their packaging line. The gap between those two numbers, multiplied by the profit per ton, is the money being lost every single day. The results are often shocking.

Here’s how a modern line compares to an older one:

| Feature | Aging Packaging Line (15+ years old) | Modern SHJLPACK Line |

|---|---|---|

| Cycle Time | 3-5 minutes per coil | 1-2 minutes per coil |

| Changeover Time | 30-60 minutes (manual adjustments) | < 5 minutes (automated, recipe-based) |

| Downtime | High (Frequent mechanical/electrical failures) | Low (Predictive maintenance, robust design) |

| Data & Diagnostics | None or very limited | Full OEE data, remote diagnostics |

| Integration | Standalone "island" of automation | Fully integrated with MES/ERP systems |

Upgrading your packaging line is not just about getting a new machine. It's about removing the brakes from your production process and allowing your mill to run at its full, profitable potential.

Can a Digitalized Packaging Line Provide the Flexibility Argentina's Market Demands?

The Argentinian steel market can be unpredictable. Customer orders can change quickly, demanding different coil sizes, weights, and specific wrapping materials. A traditional, analog packaging line struggles with this kind of variation. Every change requires a time-consuming manual setup. You have to stop the line, and an operator has to physically adjust guides, change wrapping film rolls, and modify strapping parameters. This process is slow, prone to error, and kills your efficiency. It makes it nearly impossible to accept urgent, high-margin orders for non-standard products. A digitalized packaging line, however, is built for this challenge. With pre-programmed recipes, it can switch between different packaging requirements with the touch of a button, giving you the agility to say "yes" to any customer request.

A digitalized packaging line provides critical flexibility for volatile markets like Argentina by enabling rapid, automated adjustments for different coil dimensions, materials, and wrapping specifications. This agility allows you to accept a wider variety of orders, reduce changeover downtime, and respond swiftly to shifting market demands without sacrificing efficiency.

Dive Deeper: Embracing True Production Agility

Digitalization is a term people use a lot, but what does it actually mean for a coil packaging line? It’s not just about having a touchscreen. It’s about the machine being intelligent and connected. This is something I am very passionate about at SHJLPACK because I have seen how it transforms a company's ability to compete. It's about turning your packaging line from a dumb, repetitive machine into a smart, adaptable part of your production system.

What is Recipe Management?

The core of this flexibility is a feature called "recipe management." Think of a recipe as a saved file that contains all the parameters for packaging a specific type of coil. This includes the coil's width and diameter, the type of wrapping material, the number of wraps, the position of the straps, and the tension of the strapping. When you receive an order for a new type of coil, you simply create a new recipe and save it. The next time you get an order for that same product, the operator just selects the recipe from the HMI (Human-Machine Interface), and the machine adjusts itself automatically in seconds. This eliminates manual setup errors and reduces changeover time from an hour to less than a minute.

Connecting Packaging to Your MES

The next level of digitalization is connecting your packaging line to your Manufacturing Execution System (MES). This is a key goal for forward-thinking leaders like Javier. When the packaging line is integrated, it can receive production orders directly from the MES. As a coil arrives at the packaging station, a barcode scanner identifies it, and the MES tells the packaging line which recipe to use. The machine then packages the coil, prints and applies the correct label, and sends the data back to the MES, confirming the order is complete. This creates a fully transparent, data-rich environment where you have real-time visibility of your entire process.

Here’s how a digital line handles a sudden change in orders:

| Scenario: Urgent order for 10 non-standard coils | Traditional Analog Line | Digitalized Line with MES Integration |

|---|---|---|

| Changeover Process | Manual adjustment of guides, sensors, wrapper settings. | Operator selects new recipe on HMI, or MES sends it automatically. |

| Time to First Coil | 30-60 minutes. | < 2 minutes. |

| Risk of Error | High. Incorrect settings can lead to poor packaging. | Near zero. Parameters are pre-validated. |

| Data Tracking | Manual logs, if any. | Automatic. Every coil is tracked in the MES. |

| Flexibility | Poor. Discourages taking on varied, small-batch orders. | Excellent. Can switch between different coil types seamlessly. |

This level of agility means you are no longer limited by your equipment. You can confidently serve a wider range of customers and adapt instantly to the changing demands of the Argentinian market.

What Does a "Strategic Partnership" Look Like for Modernizing Your Coil Handling?

Buying a piece of industrial machinery is a major decision. The process can be complicated, and making the wrong choice is costly. Many steel mill owners find that the relationship with a supplier ends the moment the final payment is made. They are left with a complex machine, inadequate training for their team, and no support for integrating it into their existing operations. This is a common problem, and it leaves you vulnerable. A real strategic partner operates differently. They work alongside you through the entire process—from the initial design discussions to installation, training, and long-term optimization. They act as a dedicated extension of your own engineering team, committed to your success long after the machine is running.

A strategic partnership for modernizing coil handling involves a supplier who provides a total solution, not just a machine. This includes collaborative design, seamless integration with existing systems, comprehensive training for your staff, proactive maintenance support, and expert guidance on future challenges like environmental compliance and digital upgrades.

Dive Deeper: Moving Beyond the Transaction

This is the very reason I founded SHJLPACK and why our slogan is "TOTAL SOLUTION FOR WRAPPING MACHINE." When I was an engineer, I saw companies buy expensive equipment that never reached its full potential because it wasn't the right fit or wasn't supported properly. When I started my own factory, I vowed to do things differently. A partnership is built on shared goals and trust. It's a commitment to helping you solve your problems, not just selling you a product.

Aligning with Your Long-Term Goals

A true partner takes the time to understand your business. They don't just ask about coil dimensions; they ask about your challenges and goals. They want to know about your struggles with energy costs, your plans for digitalization, and the environmental regulations you face. For a leader like Javier, who is focused on the big picture, this is critical. The right partner can provide valuable insights. For example, they can advise on energy-efficient motors and pneumatic systems to help you reduce unit energy consumption. They can ensure the equipment's control system is ready to integrate with the MES and data analytics platforms you plan to deploy. This proactive guidance is what separates a vendor from a partner.

A Partnership Across the Entire Lifecycle

The relationship should not end after the machine is installed. A good partner provides comprehensive training to empower your operators and maintenance teams. They offer proactive maintenance plans and readily available spare parts to maximize uptime. They stay in touch, sharing new ideas and technologies that could further improve your operation. This is about building a long-term relationship.

Here is what that difference looks like in practice:

| Stage | The "Vendor" Approach | The "Strategic Partner" Approach |

|---|---|---|

| Pre-Sale | Sends a standard quote. | Conducts a needs analysis, discusses long-term goals (digital, environmental). |

| Design & Engineering | Offers a one-size-fits-all machine. | Customizes the solution to fit your layout, workflow, and specific coils. |

| Installation | Ships the machine and a manual. | Provides on-site engineers for installation, commissioning, and integration. |

| Training | Minimal or optional. | Comprehensive, hands-on training for operators and maintenance staff. |

| Post-Sale Support | Reactive. You call them when something breaks. | Proactive. Offers maintenance plans, remote diagnostics, and optimization advice. |

Choosing a partner is just as important as choosing the machine itself. Your success depends on having an expert in your corner who is as invested in your plant's performance as you are.

My Insights

When I look at a complex challenge like the one facing the Argentinian steel industry, I don't just see problems. I see the same kind of opportunity that allowed me to build my career and my company. I achieved my own financial independence by solving these exact types of problems, first for my employer, and then for my own clients. The key was always to look beyond the immediate issue. The most successful steel mill owners I know, leaders like Javier, don't just buy machines. They invest in strategic capabilities. They see a packaging line not as a cost center at the end of the factory, but as a critical tool that impacts everything from production efficiency to customer satisfaction and, ultimately, profit. They understand that a smart investment here can unlock value across the entire operation. This holistic, forward-thinking approach is what will separate the winners from the losers in any challenging market.

Conclusion

Modernizing your coil packaging is not just about keeping up; it's about gaining a competitive edge in Argentina's dynamic steel market and securing your long-term success.