As a steel mill owner, you are constantly fighting a battle on multiple fronts. You face fluctuating energy prices, the relentless pressure of global competition, and the ever-present challenge of aging equipment. Every day, you look for ways to trim costs without sacrificing quality. But the packing and handling area, often seen as a simple necessity, might be silently draining your profits through hidden inefficiencies, material waste, and labor-intensive processes. This constant drain makes achieving your aggressive cost-reduction goals feel like an uphill battle.

A modern, automated steel coil packing line, like the ones we've successfully implemented for clients in demanding markets such as Indonesia, can cut your operating costs by up to 25%. This significant saving is achieved through a combination of drastic labor reduction, precise control over packaging material consumption, elimination of production bottlenecks to boost throughput, and enhanced equipment reliability that minimizes costly downtime.

You might think a 25% reduction sounds too good to be true. I understand that skepticism. As an engineer who has walked the factory floor and later built my own business, I know every investment needs to be justified with hard numbers and clear logic. That's why I want to break this down for you. Let's move past the big promises and look at the specific, practical ways a well-designed packing solution can transform your cost structure. I will show you how the principles we applied in Indonesia are directly relevant to the challenges you face in your own mill, whether it's in Mexico or anywhere else in the world.

How Does Automation Directly Tackle Rising Labor Costs and Inefficiency?

Your packing area is likely bustling with activity. You see teams of workers manually handling, wrapping, and strapping heavy steel coils. This process is not only slow and physically demanding but also expensive. You're paying for a large crew on every shift, dealing with high employee turnover, and covering the costs of training and safety compliance. These labor costs are a significant and often inflexible part of your operational budget, making it difficult to respond to market downturns.

Automation directly tackles these costs by transforming your packing area from a manual labor center into a highly efficient, machine-driven process. A fully automated line can reduce the number of operators required per shift from as many as ten down to just one or two supervisors. This system works 24/7 without fatigue, human error, or breaks, ensuring a consistent, high-speed output that manual labor simply cannot match.

The Shift from Manpower to Machine Power

Let's break down the transformation. In a manual setup, each step is a potential point of failure, delay, and cost. An automated line integrates these steps into a seamless, continuous flow. This is not just about replacing people with machines; it's about re-engineering the entire process for maximum efficiency.

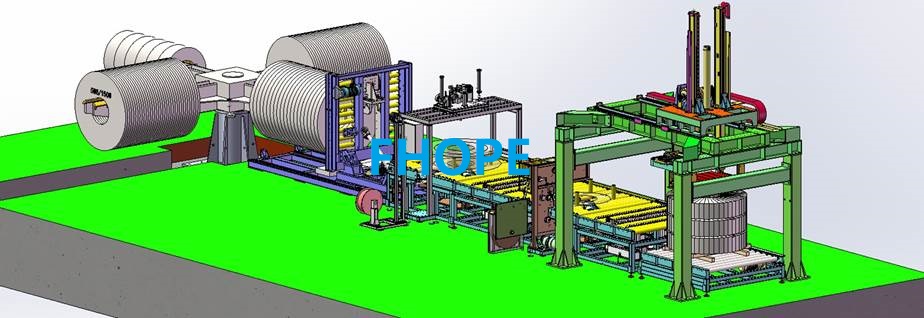

Think about the journey of a single coil. An automated system uses a series of integrated machines to handle everything:

- Coil Car & Turnstile: Safely and quickly transports the coil from your slitting line and orients it for packing. This eliminates the need for overhead cranes and ground personnel in a hazardous area.

- Orbital Wrapping Machine: Applies stretch film or VCI paper with perfect consistency and tension in under two minutes.

- Strapping Machine: Automatically applies radial or circumferential straps according to pre-programmed specifications.

- Stacking & Weighing System: Weighs, labels, and stacks the finished coils for storage or shipment.

This level of automation creates a predictable, controllable environment. You are no longer at the mercy of individual worker speed or skill. The entire packing cycle is optimized and repeatable, coil after coil.

| Feature | Manual Packing Process | Automated Packing Line |

|---|---|---|

| Labor Requirement | 6-10 operators per shift | 1-2 supervisors per shift |

| Cycle Time per Coil | 15-25 minutes | 2-4 minutes |

| Consistency | Varies by operator and shift | 100% consistent and repeatable |

| Safety | High risk of injury | Significantly reduced risk |

| Data Tracking | Manual logs, prone to error | Automatic data capture for MES/ERP |

The financial impact is immediate and substantial. By reducing your packing workforce by 80% or more, you don't just save on salaries. You also cut down on recruitment, training, and administrative overhead. More importantly, you create a safer work environment, reducing the potential for costly accidents and production stops. This is a foundational step in lowering your overall operating costs and building a more resilient, profitable operation.

Can a Modern Packing Line Really Reduce Material Waste So Significantly?

Walk through your warehouse and look at the packed coils. You might see excessive layers of stretch film or protective paper. You might notice inconsistent wrapping that leaves parts of the coil exposed, forcing workers to add extra material just to be safe. This "better safe than sorry" approach is common in manual packing, but it's incredibly wasteful. Every extra meter of film or paper used is a direct hit to your bottom line and a challenge to your environmental compliance goals.

Yes, a modern packing line can drastically reduce this waste. It uses intelligent control systems to apply the perfect amount of packaging material every single time. By precisely measuring the coil's dimensions—its outer diameter, inner diameter, and width—the machine's PLC (Programmable Logic Controller) calculates the exact material needed. This data-driven approach eliminates guesswork and over-application, often cutting material consumption by 15-30%.

Precision Engineering vs. Guesswork

The key to material savings lies in a technology called "pre-stretch." I've seen firsthand how this simple concept revolutionizes material usage. Our orbital wrappers are equipped with a powered pre-stretch carriage. This system stretches the film by 200% to 300% before it's even applied to the coil. This means that for every one meter of film on the roll, the machine applies three to four meters of stretched film to your product. This not only maximizes the yield of each roll but also creates a stronger, more secure wrap with less material.

Manual wrapping can't replicate this. A worker might pull the film tight, but they can only achieve about 20-30% stretch. To compensate, they have to walk around the coil many more times, adding layer after layer. This results in a bulky, expensive, and less effective package.

Let's look at a direct comparison:

| Metric | Manual Wrapping | Automated Wrapping with Pre-Stretch |

|---|---|---|

| Film Stretch Ratio | 20-30% | 200-300% |

| Film Used per Coil (Avg.) | 1.5 kg | 0.5 kg |

| Material Cost per Coil | ~$3.00 | ~$1.00 |

| Annual Savings (200k coils) | Baseline | $400,000 |

The numbers speak for themselves. The savings on packaging materials alone can provide a return on investment in a surprisingly short time. Furthermore, this reduction in plastic or paper consumption is a tangible achievement you can highlight in your sustainability reports. It directly addresses the growing pressure for environmental responsibility that steel mill owners like Javier face. By investing in this technology, you are not just cutting costs; you are building a greener, more efficient business that is better prepared for the future.

How Does Improved Throughput and Uptime Contribute to Lower Costs?

Your rolling and slitting lines are the heart of your operation, capable of producing coils at a high rate. But what happens when those coils reach the packing area? If manual packing can't keep up, a bottleneck forms. Coils begin to pile up, forcing you to slow down or even stop your primary production lines. Every minute your mill isn't running at full capacity is a minute of lost revenue and wasted potential. This problem directly undermines your goal of increasing capacity utilization.

Improved throughput and uptime from an automated packing line contribute to lower costs by creating a balanced and continuous production flow. An automated line can pack a coil in just two to four minutes, a task that could take 15 to 25 minutes manually. By matching or exceeding the speed of your production line, it eliminates the packing bottleneck entirely. This allows your most valuable assets—your mills—to run continuously, maximizing output and spreading your fixed costs over a larger volume of product.

From Bottleneck to Superhighway

The concept here is about creating a balanced production flow, sometimes called Takt time. If your slitting line produces one coil every five minutes, but your packing process takes fifteen, you have a critical imbalance. You are effectively limiting your entire plant's output to the speed of your slowest process. An automated line with a cycle time of three minutes completely resolves this. It creates buffer capacity in your packing area, turning it from a traffic jam into an open highway.

This increase in speed has a massive financial impact. Let's imagine your mill produces 200 tons per hour, with a profit of $50 per ton. If a packing bottleneck causes just one hour of downtime per day, you're losing $10,000 in potential profit daily. Over a year, that's millions of dollars. An automated line recaptures that lost potential.

But speed is only half the story. Uptime is just as critical, especially when dealing with aging equipment. Your goal of 95% equipment availability is ambitious but achievable. Our modern packing lines are designed for reliability and incorporate features for predictive maintenance.

| Downtime Factor | Aging Manual Process | Modern Automated Line |

|---|---|---|

| Mechanical Failures | Frequent, unpredictable breakdowns | Robust design, fewer moving parts |

| Human Error | Incorrect setup, accidents | Standardized, automated cycles |

| Maintenance | Reactive (fix when broken) | Predictive (IoT sensors flag issues) |

| Overall Uptime | ~80-85% | ~95-98% |

We integrate IoT sensors that monitor critical components like motors, bearings, and pneumatic systems. This data is fed into a control panel that can alert your team to potential issues before they cause a failure. This shift from reactive to predictive maintenance is a game-changer. It allows you to schedule maintenance during planned downtimes, rather than suffering unexpected and costly production stops. By ensuring your packing line is always ready to run, you ensure your entire operation can meet its full potential.

Vincent's Insight: Why Your Packing Line is a Strategic Asset, Not Just a Cost Center

For decades, many mill owners I've spoken with view their packing line as the last, unglamorous step in a long process. It's often treated as a necessary evil, a cost center where the primary goal is to spend as little as possible. I understand this perspective, but my journey from engineer to factory owner taught me a crucial lesson: this mindset is a strategic mistake. It leads to chronic underinvestment, creating the very cost, quality, and bottleneck issues that hold a business back.

As an engineer who has designed these systems and a business owner who has relied on them, I see things differently. Your packing line is not just an expense; it is a powerful strategic asset. It is your final quality control checkpoint, your last handshake with your customer, and a rich source of data that can drive your entire operation forward. It's where you protect the value you've created and enhance your brand's reputation.

The Final Handshake with Your Customer

When a pragmatic, forward-thinking leader like Javier Morales looks for a supplier, he's looking for a strategic partner. He's not just buying a machine. He's investing in a solution that will help him achieve his goals of digitalization, efficiency, and profitability. This is where the strategic value of the packing line truly shines.

First, consider digitalization. A modern packing line is a hub of information. When it's integrated with your MES or ERP system, it does far more than just wrap a coil. It weighs the coil, scans its production ID, and creates a final digital record. This "birth certificate" for each coil includes its weight, dimensions, grade, and packing specifications. This data is invaluable for quality assurance, inventory management, and providing full traceability to your customers. It's a key step in achieving the comprehensive production visibility you're aiming for.

Second, think about your brand. When your customer in the automotive or construction industry receives a shipment, the first thing they see is the packaging. A perfectly wrapped, clearly labeled, and undamaged coil sends a powerful message. It says you are a professional, high-quality operation that cares about your product right up to the moment it reaches their door. Conversely, a poorly packed coil that arrives damaged can erode trust and jeopardize a valuable business relationship. I learned this lesson the hard way in my early days. One damaged shipment can undo months of hard work.

Finally, a smart packing line provides strategic flexibility. Your market demands fluctuate. One month, the automotive sector needs coils packed to a specific, high-end standard. The next, the construction sector requires a more basic, cost-effective wrap. An automated line can switch between these pre-programmed "recipes" with the push of a button, allowing you to serve diverse markets efficiently without retooling or extensive manual adjustments. This agility is crucial for navigating market volatility and maintaining a balanced production schedule.

At SHJLPACK, our mission is to share this knowledge. We see ourselves as partners in your success, providing a total solution that turns your packing area from a cost center into a competitive advantage.

Conclusion

Automating your packing line directly attacks major cost drivers through labor reduction, material savings, and increased throughput. A modern steel coil packing line is a strategic investment in efficiency and quality.