You work hard to produce high-quality steel. You invest millions in your furnaces, casters, and rolling mills. Now, you're looking at the lucrative Canadian export market. But there's a final, crucial step that many steel producers overlook: the packing line. An outdated or inefficient packing line can create a massive bottleneck. It can damage your carefully made product and destroy your reputation with Canadian buyers before you even secure your first long-term contract.

Imagine this scenario. You have a multi-million dollar order for a major distributor in Toronto. Your mill runs flawlessly to meet the deadline. But your packing line, a piece of equipment that's over 15 years old, can't keep up. Coils start piling up. Your team rushes, but the wraps are loose, and the strapping isn't secure. The coils are loaded onto a ship for the long journey through the St. Lawrence Seaway. They arrive, but condensation and movement have taken their toll. The customer finds rust spots and damaged edges. They reject the entire shipment. Now, you're not just facing a huge financial loss; you're dealing with a damaged relationship in a market that values reliability above all else. This isn't a hypothetical problem. I've seen it happen.

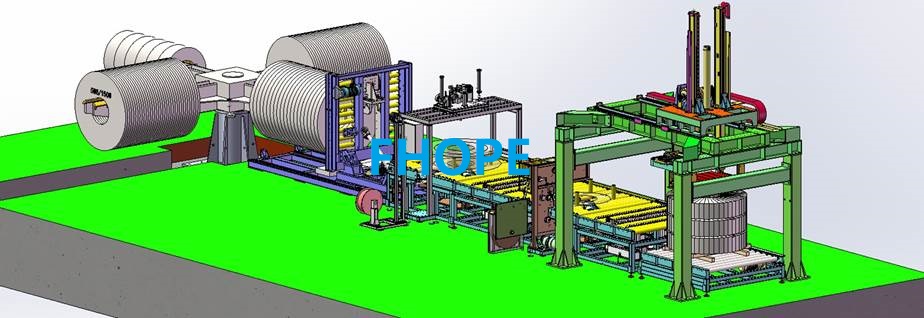

The solution isn't just buying a faster machine. It's about implementing a total solution—a fully integrated coil packing line designed for the specific, demanding requirements of export markets like Canada. It's a strategic investment that protects your product, ensures on-time delivery, and builds the foundation of trust with your Canadian partners.

Yes, your coil packing line can be fully capable of handling the demands of Canada's steel exports, but only if it is a modern, automated system. A successful line must offer high throughput to meet shipping schedules, use a smart material strategy to protect against harsh transit conditions, provide full data traceability for compliance, and be flexible enough to handle diverse coil specifications demanded by Canadian customers.

Throughout my career, from my first days on the factory floor to building my own company, SHJLPACK, I've seen how the final 1% of the production process—the packing—can determine 100% of the success of an export operation. Too many good steelmakers are held back by this final step. They have the production capacity but lack the packaging capability.

Let's break this down. I want to walk you through the four critical questions you must ask about your current line. Answering these honestly will reveal if you are truly prepared to compete and win in the Canadian steel market.

How can modernizing your coil packing line boost throughput for Canadian export standards?

Your mill is a high-speed operation, capable of producing thousands of tons of steel per day. But if your packing line moves at a crawl, your entire operation is throttled. This bottleneck directly limits your output, making it impossible to meet the tight shipping schedules required for Canadian exports. Every hour your packing line is down for a changeover or a breakdown, you are losing money and risking your delivery promises. An old, unreliable line can turn a profitable export contract into a logistical nightmare. You simply cannot afford for the last step in your process to be the weakest link.

A modern, automated coil packing line is the solution. It doesn't just work faster; it works smarter. It integrates seamlessly with your production flow, eliminating the manual slowdowns and inconsistencies that plague older systems. This creates a steady, predictable, and reliable flow of perfectly packed coils, ready for the demanding journey to Canada.

Modernizing your coil packing line boosts throughput primarily by automating key processes. This includes automatic coil loading, strapping, wrapping, and labeling. By drastically reducing cycle times and minimizing human error, an automated line can operate continuously, directly increasing the number of coils you can prepare for export to Canada each shift.

Dive Deeper: The Anatomy of Speed and Reliability

When I consult with steel mill owners like yourself, the first thing we analyze is the time lost between process steps. A modern line isn't just about faster individual machines; it's about eliminating the "in-between" time.

The Bottleneck Breakdown: Manual vs. Automated

I remember visiting a plant with a semi-automatic line that was over 15 years old. The process was painful to watch. A crane operator would carefully lower a coil onto a skid. Then, two workers would manually feed PET straps through the coil eye, tighten them with a hand tool, and cut them. Next, they would walk around the coil with a roll of stretch film. The whole process took nearly 15 minutes per coil and depended heavily on the skill and speed of the workers. This is a massive bottleneck.

A modern line transforms this. The coil arrives via an automated conveyor. A turnstile positions it perfectly. The automatic strapping head applies the straps in under a minute. The orbital wrapper completes its cycle in two minutes. The entire cycle time is cut by more than 70%. This is how you achieve the throughput needed for export.

Integrated Systems for Maximum Uptime

A modern line is a single, cohesive system, not a collection of separate machines. It talks to your Manufacturing Execution System (MES). Your MES tells the packing line what coil is coming next—its size, weight, and the customer's specific packing requirements. The line adjusts itself automatically. This seamless integration is critical for achieving the kind of uptime—95% or higher—that profitable mills require. It eliminates human error in setup and drastically cuts down on changeover time.

Predictive Maintenance: A Game Changer

Furthermore, modern lines are equipped with IoT sensors. These sensors monitor motor temperature, belt tension, and cycle counts. This data feeds into a predictive maintenance platform. The system can alert you that a motor is showing signs of stress before it fails. This allows you to schedule maintenance during planned downtime, rather than suffering a catastrophic failure during a critical production run. This proactive approach is fundamental to maintaining high throughput and meeting Canadian export deadlines without fail.

| Process Step | Traditional Line (Manual/Semi-Auto) | Modern Automated Line | Throughput Impact |

|---|---|---|---|

| Coil Loading | 5-10 minutes (crane + manual positioning) | < 1 minute (conveyor + turnstile) | Drastically reduces idle time between coils |

| Strapping | 2-4 minutes per coil (manual tools) | 30-60 seconds per coil (auto strapper) | Over 75% time saving, highly consistent |

| Wrapping | 3-5 minutes per coil (manual walking) | 1-2 minutes per coil (orbital wrapper) | Faster, more secure, and consistent wrap |

| Labeling/Marking | 1-2 minutes (manual stenciling) | < 15 seconds (auto print & apply) | Eliminates errors, increases speed |

| Total Cycle Time | 11-21 minutes per coil | < 5 minutes per coil | ~300% increase in potential throughput |

Is your current packing material strategy wasting money in the competitive Canadian market?

In an effort to control costs, many managers default to the cheapest packing materials available. They see a lower price per roll for stretch film or VCI paper and think they are saving money. The reality is that this approach often leads to product damage, customer claims, and a higher total cost. The "savings" from a cheap roll of VCI paper evaporate the moment a Canadian customer rejects a coil due to rust. The cost of that single rejected coil—including return shipping, reprocessing, and reputational damage—can easily wipe out an entire year's worth of supposed savings on materials.

A smart material strategy is not about finding the lowest price per unit. It is about achieving the lowest total cost of ownership. This means using the right material, with the right performance characteristics for the harsh Canadian shipping environment, and applying it efficiently with a modern machine. This is how you protect your product, your profits, and your relationships.

Yes, your current packing material strategy is very likely wasting money if it prioritizes low upfront cost over performance. Using sub-optimal or excessive amounts of material leads directly to product damage, rework, and customer claims. These hidden costs are almost always far greater than the investment in the correct, high-performance materials required for protecting steel exports to Canada.

Dive Deeper: The True Cost of "Cheap" Materials

The journey to Canada is not a short trip across town. It can involve trucks, trains, and ocean vessels, exposing your steel coils to humidity, salt spray, and extreme temperature swings. Your packaging is its only defense.

Material Science: More Than Just a Wrapper

Let's talk about VCI, or Volatile Corrosion Inhibitor. This technology is critical for preventing rust. VCI paper or film is infused with chemical compounds that vaporize and form a protective, invisible layer on the surface of the steel. But not all VCI is created equal. A low-cost VCI product might have a lower concentration of inhibitors, or it might release them too quickly, leaving the coil unprotected for the latter part of its journey. For shipments to Canadian ports like Vancouver or Montreal, which can take weeks, using a high-quality, long-lasting VCI is non-negotiable. It's an investment, not a cost.

The Cost of Over-Wrapping vs. Optimized Wrapping

Another area of waste is the material application itself. Older wrapping machines are often "dumb." They apply the same amount of stretch film with the same tension to every single coil, regardless of its size or weight. To be safe, operators often add extra layers, leading to massive waste. I had a client who was using an old turntable wrapper. After we installed a new orbital wrapping machine, we did an analysis. The new machine, with its programmable tension controls and precise overlap settings, used 28% less stretch film per coil while providing a more secure and protective wrap. The annual savings on film alone were enough to pay for the new machine in just over two years. This is a direct contribution to your goal of lowering overall operating costs. A modern line doesn't just wrap; it optimizes.

| Cost Factor | Low-Cost Material Strategy | Optimized Material Strategy | Financial Impact |

|---|---|---|---|

| Upfront Material Cost | Low | Moderate | Initially misleading "savings" |

| Material Consumption | High (due to over-wrapping) | Optimized (precise, automated application) | 20-30% reduction in annual material spend |

| Labor Cost | High (manual, slow application) | Low (fully automated) | Significant reduction in man-hours per coil |

| Damage/Claim Rate | High (poor protection, rust) | Negligible (superior, reliable protection) | Avoids huge losses from rejected shipments |

| Total Cost Per Coil | Deceptively High | Demonstrably Lower | Improved overall profitability and reliability |

Does your packing line’s data meet Canadian traceability and sustainability requirements?

Your Canadian customers and regulators are demanding more than just a high-quality product delivered on time. They want data. They want to know the full history of each coil. They want proof of quality control at every step, and they want to see that you are a sustainable and responsible partner. An old packing line that operates as a "black box" cannot provide this. If you can't produce a detailed report for every coil you ship, you look unprofessional and raise immediate red flags about your entire operation. In today's market, a lack of data is a major liability that can get you shut out of sophisticated supply chains.

The solution is a packing line that is not just a piece of mechanical equipment, but an intelligent information hub. A modern line captures a wealth of critical data for every single coil that passes through it. It provides the detailed traceability and sustainability reports that Canadian partners now consider standard practice.

Most likely, no. The vast majority of older coil packing lines operate as isolated "islands" with zero data collection capabilities. To meet modern Canadian requirements, you need a packing line that is fully integrated with your plant's MES. It must be able to record every step of the packing process, track the consumption of materials, and assign a unique digital identity to each coil for complete, end-to-end traceability.

Dive Deeper: Transforming Dumb Iron into a Smart Asset

This is where we move into the realm of Industry 4.0, a topic I know is important to forward-thinking leaders like yourself. Your packing line should be a key part of your digital transformation strategy.

From a Black Box to a Digital Twin

An old machine just runs. It performs a task, but it doesn't tell you anything. A smart line, connected with IoT sensors, is completely different. It becomes a rich source of data. For every coil, it can record:

- The unique Coil ID, scanned from the coil itself.

- The exact time and date of packing.

- The Operator ID.

- The exact packing "recipe" used.

- The precise length of strapping and weight of stretch film consumed.

- A final, high-resolution photo of the finished, packed coil, automatically linked to the Coil ID.

This creates a "digital twin" of the packed product. I helped a client in Mexico implement exactly this kind of system. They were supplying the automotive sector in the US and Canada. When their customer had a quality question about a specific coil, my client could instantly pull up the complete packing record, including the photo, proving the coil left their facility in perfect condition. This data-driven approach builds immense trust and resolves disputes instantly.

The Power of Data for Sustainability

Sustainability is not just a buzzword in Canada; it's a core business principle. Data from your packing line is essential for proving your environmental credentials. When you can show, with hard data, that you have optimized your film usage to reduce plastic waste, you are speaking your customer's language. This data helps you track progress against your own internal goals, such as reducing operating costs and energy consumption. It transforms your sustainability report from a collection of vague promises into a document filled with verifiable facts. This can be a powerful competitive advantage.

| Data Point | Traditional Line (No Data) | Smart Packing Line (Integrated) | Value for Canadian Exports |

|---|---|---|---|

| Coil Identification | Manual logs, prone to error | Barcode/QR scan linked directly to MES | 100% accurate and instant traceability |

| Packing Recipe | Operator memory or paper notes | Digital recipe pulled from MES | Guarantees consistency and quality assurance |

| Material Usage | Rough estimates, if any | Precise measurement of film/strap per coil | Proof of resource optimization for ESG reports |

| Quality Verification | Visual check by operator | Automatic photo of finished packed coil | Visual proof of package integrity before shipping |

| Result | No traceability, high risk | Full digital record, low risk | Meets compliance, builds trust, proves quality |

How adaptable is your packing line to the diverse coil sizes and types demanded by Canadian buyers?

Your current packing line might be very efficient, but only for one or two standard coil sizes. The Canadian market, however, is not standardized. Your customers may require a wide variety of products, from very narrow slit coils for the automotive industry to wide master coils for service centers. They will order different steel grades, which may have different packing requirements. If your packing line is inflexible, this diversity becomes a major problem.

Every time a coil with different dimensions arrives, your entire line grinds to a halt. Your team has to get out their tools and manually adjust conveyor guides, move sensor positions, change the strapping setup, and re-thread the wrapping machine. This downtime destroys your efficiency and makes you slow to respond to your customers' needs. You become a bottleneck for your own business.

A truly adaptable packing line is engineered for flexibility. It is designed to handle a wide range of coil sizes and specifications with minimal or even zero manual changeover time. It uses automation to switch between different packing "recipes" in seconds, giving you the agility to say "yes" to any Canadian customer, no matter what they order.

An adaptable packing line is absolutely critical for serving Canadian buyers, who frequently order a mix of coil specifications. A modern line achieves this adaptability through automated adjustments for coil diameter, width, and weight. It stores pre-programmed packing recipes that can be selected instantly from the HMI or MES, completely eliminating the costly downtime associated with manual changeovers.

Dive Deeper: Engineering for Agility

In my early days as an engineer, we designed machines for a single purpose. They did one thing very well. But the modern steel market punishes that kind of rigidity. Agility is the new key to profitability. I will never forget a client who had to turn down a massive, multi-year contract from a Canadian auto parts manufacturer. They could produce the high-strength steel the customer needed, but their packing line simply couldn't handle the narrow slit coils required. They could make the steel, but they couldn't ship it. That experience taught me that the packing line's flexibility must match the mill's production flexibility.

The Mechanics of Adaptability

So, how do we build this adaptability into the hardware? It's about smart design from the ground up.

- Conveyors: We don't use fixed guides. We use heavy-duty V-shaped or flat-top conveyors with motorized, adjustable side rollers that automatically center the coil, regardless of its width.

- Strapping Heads: The strapping head is mounted on a movable gantry. It can move horizontally to find the center of a narrow coil and vertically to accommodate different diameters.

- Orbital Wrappers: The "ring" of the wrapper is sized to handle the largest and smallest diameters you produce. The control system then automatically calculates the required wrapping speed and film overlap based on the coil's width, ensuring a perfect wrap every time.

Recipe Management: The Brain of Adaptability

This is where the hardware connects with the digital intelligence I mentioned earlier. This is the key to eliminating downtime. Your MES or a local HMI stores dozens of packing "recipes." Each recipe contains all the parameters for a specific product: conveyor guide positions, strapping locations, number of wraps, film tension, etc.

When your system identifies an incoming coil (e.g., Coil #ABC123, 400mm width, 1400mm OD), it automatically loads "Recipe 12." The guides motor into position. The strapper moves to its pre-defined points. The wrapper sets the correct overlap. The operator simply confirms the coil ID and presses the "Start" button. A process that used to take 20 minutes of manual labor now happens in under 20 seconds. This is how you handle market fluctuations and diverse orders without sacrificing an ounce of efficiency.

| Feature | Fixed, Inflexible Line | Modern, Adaptable Line | Benefit for Serving the Canadian Market |

|---|---|---|---|

| Coil Width Range | Very limited (e.g., 900-1200mm) | Very wide (e.g., 200-1600mm) | You can accept orders for slit and master coils |

| Coil OD Range | Limited | Wide | Handles both small, specialized and large coils |

| Changeover Time | 15-30 minutes (manual tools & labor) | < 1 minute (automatic recipe selection) | Maximizes uptime and operational agility |

| Operator Skill | Requires experienced, highly trained operator | Simple, intuitive push-button operation | Reduces training costs and eliminates errors |

| Result | You are forced to turn down business | You can say "yes" to more customers | Increased market share and revenue streams |

Conclusion

Upgrading your coil packing line is not an expense. It is a strategic investment in efficiency, quality, and market access, making you a preferred partner for Canadian steel exports.