Choosing major equipment for a new factory is one of the biggest decisions a leader can make. I remember when I was starting my own factory, the pressure to get every detail right was immense. You are not just buying a piece of steel; you are investing in the heart of your production's final stage. If you're establishing a steel processing facility in a market like Thailand, selecting the right coil packing line is critical. A mistake here doesn't just cost money upfront; it can create bottlenecks that cripple your entire operation, damage your reputation with customers, and turn a promising venture into a constant headache. But it doesn't have to be this way. By following a clear, strategic process, you can choose a packing line that not only fits your needs perfectly today but also helps you grow and adapt for years to come.

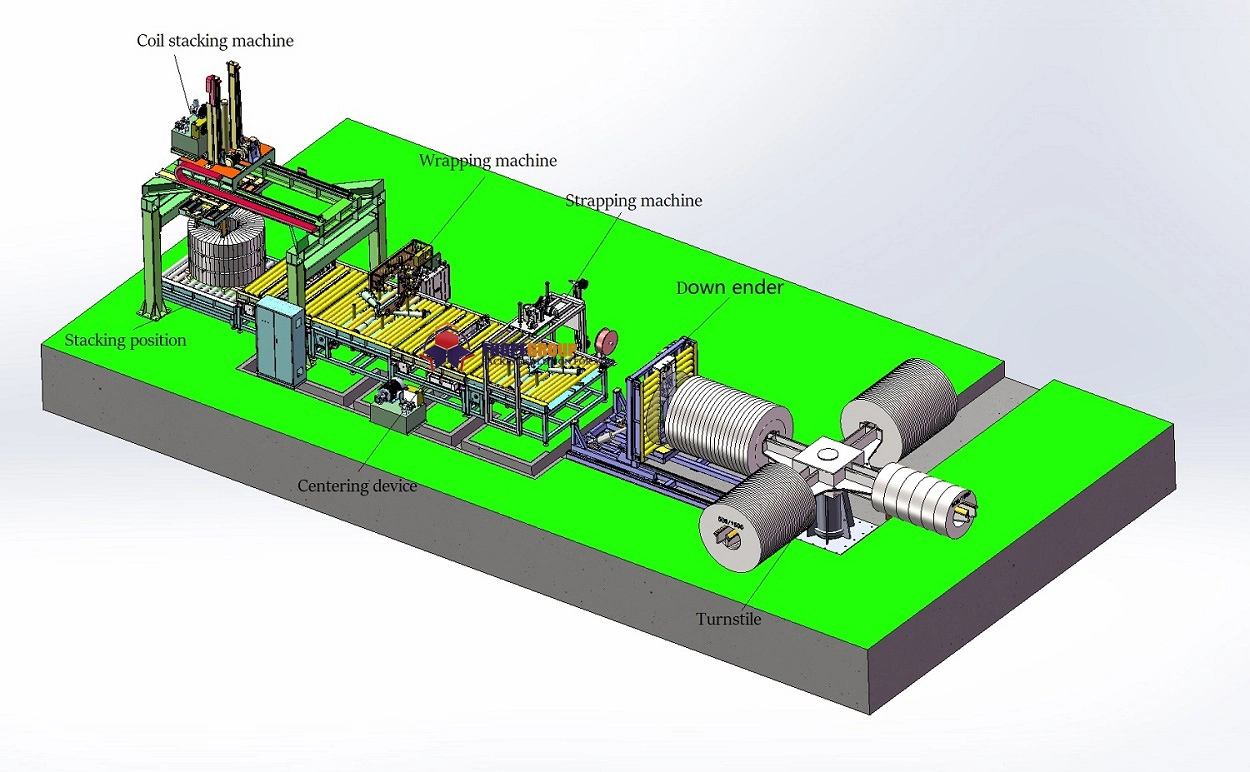

Choosing the right coil packing line for your factory in Thailand requires a comprehensive analysis of four key areas: your production capacity and coil specifications, the appropriate level of automation for your operational goals, compliance with local safety and environmental standards, and a thorough calculation of the total cost of ownership (TCO) beyond the initial price.

This decision is about much more than just the machine's price tag. It's a strategic investment in your plant's efficiency, safety, and future profitability. A steel mill owner I know, a man who runs a 2-million-ton-per-year facility, once told me, "I don't buy equipment, I buy production stability and a path to lower costs." He is absolutely right. To help you make a decision with that same mindset, I want to walk you through the essential questions you must ask. Let’s break it down together.

How do you align a new packing line with your production capacity and goals?

You have a clear production target for your mill. But what happens if the very last step, the packing line, can't keep up? I have seen this happen. Expensive production machinery sits idle while finished coils pile up, waiting to be wrapped. This creates a massive bottleneck that ripples backward through your entire operation. Your shipping schedules get delayed, your customers get frustrated, and your goal of achieving high capacity utilization becomes impossible. The only way to prevent this is to precisely match your packing line's capabilities to your mill's output and your long-term business goals.

To align a packing line with your factory's goals, you must first analyze your current and future production volume, the full range of your coil sizes and weights, and your target packing speed in coils per hour. This data ensures the line can handle your peak output without slowing you down and directly supports strategic objectives like increasing overall capacity utilization.

A Deeper Look at Your Production Needs

Matching a packing line to your factory is a science. It begins with data. You can't make a good decision based on feelings or rough estimates. You need hard numbers that reflect your reality.

Analyzing Your Coil Specifications

First, we need to understand exactly what you are packing. The physical dimensions of your steel coils are the foundation for the machine's design. A line designed for narrow, light coils will fail if you try to run wide, heavy ones through it. You must document the full range.

| Coil Parameter | Why It Matters | Example Range |

|---|---|---|

| Inner Diameter (ID) | Determines the size of the packing shuttle or "eye." | 508mm - 610mm |

| Outer Diameter (OD) | Affects the machine's overall size and wrapping cycle time. | 1200mm - 2100mm |

| Coil Width | Dictates the length of the wrapping material and support rollers. | 300mm - 1850mm |

| Coil Weight | Defines the required strength of the conveyor, tilter, and structure. | 5 tons - 30 tons |

Gathering this data is your first step. Don't just consider your most common product. Think about the largest, smallest, heaviest, and lightest coils you might produce. A versatile machine that can handle your entire range is a much better long-term asset.

Calculating Your Required Throughput

Next, let's talk about speed. Your packing line must keep pace with your production. Let's say your goal is to hit a 95% equipment effective run time. You need to calculate your required packing rate. For a large mill, the math might look something like this:

- Annual Production: 2,000,000 tons

- Operating Days: 350 days/year

- Daily Production: 5,714 tons/day

- Average Coil Weight: 15 tons

- Coils Per Day: 381 coils

- Operating Hours: 22 hours/day (allowing for 2 hours of maintenance)

- Required Packing Speed: ~18 coils/hour

Your line must be able to comfortably handle 18 coils every hour. You should even build in a small buffer, perhaps aiming for a machine capable of 20-22 coils per hour, to account for variations in production.

Planning for Future Growth

The packing line you buy today should serve you for the next 15 years. Your business will grow and change. Your partner in this should ask, "Where do you see your production in five years? In ten years?" A forward-thinking design is modular. Maybe today you only need a basic wrapping station. But in the future, you might want to add automatic strapping, weighing, and labeling. A modular design allows you to add these functions later without replacing the entire line. This protects your initial investment and gives you a clear path for upgrades.

What level of automation is right for your steel mill?

Many factory owners I speak with are excited by the promise of automation. They want to reduce labor costs and improve efficiency, which are excellent goals. But they are also concerned about the high initial investment and complexity of a fully automated system. Choosing the wrong level of automation is a costly mistake. You might overspend on advanced features that your process doesn't require. Or, you could choose a system that is too manual, leaving you with high labor costs, inconsistent quality, and a process that can't keep up with demand. The goal is to find the perfect balance—the level of automation that delivers the best return on your investment.

The right level of automation for your steel mill is determined by your local labor costs, required throughput, quality control standards, and long-term digitalization strategy. A semi-automatic line often provides the best balance of cost and efficiency, while a fully automatic line is best for high-volume plants focused on integrating with MES and IoT platforms for complete process control.

Finding Your Automation Sweet Spot

Deciding on the level of automation is a strategic choice, not just a technical one. It should directly support your business goals, like reducing operational costs by a target percentage. Let's break down the options to see which one aligns with your vision.

Manual vs. Semi-Automatic vs. Fully Automatic

Each level comes with different trade-offs. There is no single "best" choice; there is only the best choice for your factory.

| Level | Initial Cost | Operating Cost | Throughput | Flexibility | MES/IoT Integration |

|---|---|---|---|---|---|

| Manual | Low | High (Labor) | Low (5-8 coils/hr) | High | None |

| Semi-Automatic | Medium | Medium | Medium (10-20 coils/hr) | Medium | Basic Data Output |

| Fully Automatic | High | Low (Minimal Labor) | High (20+ coils/hr) | Low | Full Integration |

For a large-scale operation in a place like Thailand, where skilled labor may be available but consistency is key, a semi-automatic line is often the ideal starting point. It automates the most critical tasks—wrapping, cutting the film, and conveying—while still allowing for human oversight. A fully automatic line is the right choice if your primary goal is maximum throughput and complete integration into a "smart factory" environment.

The Role of Automation in Quality and Cost Reduction

Automation is not just about speed; it is about consistency. An automated wrapper applies the exact same amount of stretch film with the exact same tension on every single coil. This precision does two things. First, it ensures your product is protected perfectly every time, reducing damage during shipping. Second, it optimizes your use of consumables. I had a client who switched from manual wrapping to a semi-automatic line. They reduced their stretch film consumption by over 30% because the machine eliminated the waste that comes from human inconsistency. That saving went directly to their bottom line, helping them achieve their cost-reduction targets.

Integrating with Your Digital Factory

For a forward-thinking leader, a packing line is not an isolated island. It should be a node in your factory's digital ecosystem. This is where automation becomes truly powerful. A fully automated line can be equipped with sensors that connect directly to your Manufacturing Execution System (MES) and data analytics platforms. This is a key part of achieving the "total production visualization" you're aiming for. The line can automatically send data for each coil:

- Coil ID and weight

- Packing start and end time

- Amount of packing material used

- Operator ID

This data gives you incredible insight into your process. You can track efficiency in real-time, perform predictive maintenance, and have a complete digital record for every product that leaves your factory.

How can a packing line address specific environmental and safety regulations in Thailand (and globally)?

Navigating the web of government regulations is a major challenge for any industrial operation. In growing economies like Thailand, and established ones like Mexico, the rules for environmental protection and worker safety are only getting stricter. Installing a new piece of equipment that fails to meet these standards is not just a poor investment; it's a significant legal and financial risk. A single accident or a fine for non-compliance can shut down your operations and severely damage your company's reputation. The good news is that a modern coil packing line is designed from the ground up to meet these challenges, helping you create a safer workplace and a more sustainable operation.

A modern coil packing line addresses regulations by incorporating robust safety systems like physical guarding and light curtains to meet international standards (like CE and ISO). For environmental compliance, it is engineered to minimize packaging material waste through precise, automated application and to reduce energy use with high-efficiency motors, helping you lower costs and meet sustainability goals.

Engineering for a Safe and Compliant Operation

Safety and environmental compliance are not optional add-ons. They must be built into the core design of the machine. When you evaluate a potential line, you are also evaluating your potential partner's commitment to these principles.

Key Safety Features to Look For

When I walk a factory floor, I can immediately tell if the equipment was designed with safety as a priority. For a coil packing line, here are the non-negotiable features you should demand:

- Full Physical Guarding: All moving parts, especially the rotating ring, must be enclosed by strong safety fencing with interlocking gates. If a gate is opened, the machine must stop immediately.

- Light Curtains: These create an invisible barrier of light at the entrance and exit of the packing station. If a person or object breaks the beam while the machine is in a dangerous cycle, it instantly triggers an emergency stop.

- Emergency Stops (E-Stops): There should be multiple, easily accessible E-stop buttons placed around the machine.

- Warning Systems: Audible alarms and flashing lights should signal when the machine is about to start a cycle.

- Certified Components: The machine should be built with components that meet recognized international standards and, ideally, be certified to CE (for Europe) or equivalent standards, which are recognized as a benchmark for safety globally.

Environmental Compliance and Cost Savings

Meeting environmental regulations often comes with a powerful side effect: it saves you money. This directly supports your goals of reducing energy consumption and lowering overall operating costs. A well-designed packing line contributes in two main ways:

- Material Reduction: As I mentioned before, automation is precise. It can be programmed to use the minimum amount of VCI paper and stretch film required to protect the coil, eliminating waste. This not only cuts your consumable costs but also reduces your environmental footprint.

- Energy Efficiency: Modern machines use high-efficiency motors and variable frequency drives (VFDs). A VFD allows a motor to use only the power it needs for a specific task, rather than running at full speed all the time. The line can also be programmed with an intelligent power-down mode, so it enters a low-energy state when it's idle for a set period. These features can significantly contribute to your goal of a 10% reduction in unit product energy consumption.

While the specifics of Thailand's Safety, Occupational Health, and Environment Act are important for a local project, the principles are universal. The safety and environmental features required to operate in Thailand are quickly becoming the global standard. Investing in a compliant machine is not just about meeting local rules; it's about future-proofing your operation for any market in the world.

How do you calculate the Total Cost of Ownership (TCO) for a coil packing line?

It is very easy to focus on the initial purchase price of a machine. It's the biggest number on the quote, and it's a simple way to compare different suppliers. But focusing only on that price is a classic mistake. I learned this lesson the hard way early in my career. We bought a cheaper machine, and it felt like a victory for about six months. Then the problems started. It used more energy, the spare parts were expensive and slow to arrive, and it broke down constantly. The money we "saved" upfront was quickly eaten up by high operating costs and lost production. A true business leader understands that you must look at the Total Cost of Ownership (TCO) to understand the real financial impact of your investment.

To calculate the Total Cost of Ownership (TCO) for a coil packing line, you must look beyond the initial price. You need to sum all costs over the machine's entire lifespan, including installation, training, energy consumption, consumables like stretch film, spare parts, and the projected financial impact of maintenance and potential downtime. This gives you the true cost of the investment.

Looking Beyond the Price Tag

A rigorous financial analysis is something any successful owner does for every major investment. The TCO framework is the perfect tool for this because it forces you to consider the long-term reality, not just the short-term purchase.

Breaking Down the TCO Formula

The concept is simple: you add up all the costs associated with the machine over its life. A typical lifespan for a quality packing line is 15-20 years. The basic formula is:

TCO = Initial Purchase Cost + Lifetime Operating Costs + Lifetime Maintenance Costs

Let's look at what goes into the operating and maintenance buckets.

The Hidden Costs of Operation and Maintenance

This is where a cheap machine reveals its true cost. A detailed comparison might look like this:

| Cost Component | High-Quality Line (Example) | Low-Quality Line (Example) |

|---|---|---|

| Initial Price | $250,000 | $180,000 |

| Energy Costs (10 yrs) | $80,000 (VFDs, efficient motors) | $120,000 (standard motors) |

| Consumable Waste (10 yrs) | $15,000 (overuse of film) | $45,000 (imprecise application) |

| Spare Parts (10 yrs) | $20,000 (standard, reliable parts) | $50,000 (proprietary, frequent failure) |

| Downtime Costs (10 yrs) | $50,000 (based on 98% uptime) | $250,000 (based on 90% uptime) |

| Total 10-Year TCO | $415,000 | $645,000 |

As you can see, the machine that was $70,000 cheaper to buy ended up costing $230,000 more over a decade. This is why a strict focus on ROI requires a TCO analysis.

A Smart Maintenance and Spare Parts Strategy

Your uptime goal of 95% is ambitious and correct. But you can't achieve it without a solid maintenance plan. This is another area where a good supplier proves its value. They should provide you with a detailed preventative maintenance schedule. This tells your team exactly what to check, what to lubricate, and what to tighten on a daily, weekly, and monthly basis. This is the foundation of predictive maintenance.

Furthermore, they should provide a recommended list of critical spare parts to keep on-site. These are items like sensors, belts, or small motors that might wear out over time. Having them in your own stockroom means a repair takes hours, not days or weeks waiting for a shipment. This strategy of proactive maintenance and smart inventory is essential to minimizing downtime and protecting your profitability.

What should you look for in a long-term strategic partner, not just a supplier?

You have analyzed your capacity, determined the right level of automation, and calculated the TCO. You have quotes in hand. Now comes the most important decision of all: who do you trust with your business? Many companies can sell you a machine. They can meet the technical specifications and offer a competitive price. But a machine is only a tool. A simple supplier sells you the tool and walks away. A strategic partner, however, invests in your success. They understand that if your business grows and thrives, so will theirs. This is the final and most critical filter you should apply.

A strategic partner provides comprehensive support that extends far beyond the initial sale. You should look for a company with deep engineering expertise in your industry, a proven track record with verifiable references, highly responsive after-sales service, and the ability to act as a consultant, offering strategic advice on process optimization, digitalization, and future technology.

Beyond the Machine: The Importance of Engineering Expertise

This is a value I built my own company, SHJLPACK, on. I started my journey as an engineer on the factory floor. I wasn't just designing machines; I was living with them, fixing them, and seeing how they impacted the entire production process. When I started my own factory, that experience was invaluable. This is what you should look for in a partner. Their engineers shouldn't just know their own equipment; they must strive to understand your business. They should ask intelligent questions about your production flow, your material handling, your biggest challenges, and your most ambitious goals. A true engineering partner helps you design a solution, not just sell you a product.

Evaluating After-Sales Support

A machine is a complex system, and things will eventually need service. The quality of a company's after-sales support is a true measure of their commitment. Before you sign a contract, ask these direct questions:

- What is your standard warranty, and what does it cover?

- What is your guaranteed response time for a service request?

- Do you offer 24/7 remote technical support?

- What kind of training do you provide for our operators and maintenance staff? Is it on-site?

- How quickly can you supply critical spare parts?

A partner will have clear, confident answers to these questions. A simple supplier will be vague. The quality of this support system is a direct input into your TCO calculation, as it determines the length and cost of any potential downtime.

A Partnership for the Future

Finally, a strategic partner helps you look around the corner. The steel industry is constantly evolving. A partner should be more than a vendor; they should be a source of knowledge. They should be talking to you about new developments in sustainable packaging materials, advancements in IoT sensor technology, and new ways to analyze data to improve efficiency. This is exactly why I founded SHJLPACK on the principle of knowledge sharing. My goal is not just to sell machines but to share the expertise I've gained over decades in this industry. A real partner is proactive. They bring you ideas. They challenge you. They are committed to helping you achieve your goals of digitalization and continuous improvement because they see themselves as part of your long-term journey.

Conclusion

Choosing the right coil packing line is a strategic decision. Focus on capacity, automation, TCO, and finding a true partner who is dedicated to your long-term success.