Are you managing a steel plant in Russia? You probably feel the constant pressure to increase output. You need to ship more coils, faster. But your packaging line is holding you back. Your team wraps heavy steel coils by hand. It's slow, it's dangerous, and sometimes the coils get damaged. This bottleneck costs you time and money. It creates a stressful environment where meeting deadlines feels impossible. You know there has to be a better way to protect your products and improve your plant's performance.

Russian steel plants can dramatically boost productivity by switching from manual labor to automated coil packaging solutions. These systems increase wrapping speed, significantly improve worker safety, and provide superior protection for steel coils. This automation directly resolves major production bottlenecks, leading to higher throughput and reduced operational costs.

Investing in new equipment is a big decision. It’s not just about buying a machine. It's about finding the right solution for your specific problems. You need to understand the hidden costs of your current process. Then you can see how the right automation can offer a powerful return on your investment. Let's break down the common challenges I see in plants like yours and explore how a well-designed packaging line can solve them for good.

What are the core challenges in traditional steel coil packaging in Russia?

You watch your workers struggle with heavy rolls of packing material. They move slowly around a massive steel coil. The process is physically draining. You know it’s a major weak point in your entire production line. Every moment your team spends on manual wrapping is a moment your shipping bay doors are closed. You worry about the constant risk of injury. A single mistake could lead to a serious accident and a long-term worker's compensation claim. Worse, when a customer calls to complain about a damaged coil edge, you know that loss comes directly from your bottom line. Facing these issues day after day is frustrating. But identifying these specific problems is the first step to fixing them permanently.

The primary challenges of traditional steel coil packaging in Russia include severe inefficiency, major safety hazards for employees, frequent product damage during handling, and inconsistent quality of the final package. These problems combine to create significant production delays and direct financial losses.

Dive Deeper: The Real Costs of Manual Packaging

Let’s get more specific about these challenges. They are not just small annoyances; they are serious operational drains that impact your plant's profitability and reputation.

The Efficiency Bottleneck

Manual packaging is incredibly slow. Think about the steps involved. Workers have to fetch the wrapping materials, walk around the coil multiple times, and secure the wrap. I once timed a team at a client's factory. It took two workers nearly 20 minutes to properly wrap one medium-sized steel coil. In contrast, a basic automatic wrapping machine can do the same job in under two minutes with one supervisor. This difference is huge. If you produce 100 coils a day, manual wrapping costs you over 33 hours of labor. An automated system would take less than 4 hours. This manual bottleneck means your expensive rolling mills and slitters might have to slow down or stop, waiting for the packaging line to catch up. Your trucks are waiting longer, which can lead to detention fees. You simply cannot achieve a high-throughput operation with a low-throughput packaging process. It holds the entire plant hostage.

The High Cost of Worker Safety

This is a topic I am very passionate about. Before I started my own factory, I worked on the floor. I know how physically demanding this work is. Manual packaging of steel coils is one of the most dangerous jobs in a steel plant. Workers are constantly handling heavy materials, bending in awkward positions, and working near heavy, unstable loads. Common injuries include severe back strain from lifting, repetitive stress injuries from wrapping motions, and cuts from sharp metal edges. These injuries are not just statistics. They affect real people and their families. From a business perspective, the costs are enormous. Higher insurance premiums, lost workdays, and the cost of hiring and training replacements all add up. In today's labor market, it is increasingly difficult to find people willing to do such strenuous and risky work. High employee turnover in your packaging department becomes another hidden cost. Automation removes the person from the most hazardous tasks, creating a safer and more stable work environment.

The Hidden Losses from Product Damage

Your steel coils are valuable. The edges are especially vulnerable. During manual wrapping and handling, it's very easy for a coil to be bumped or for the wrap to be applied too loosely. This can lead to edge damage, water spots, or rust during transport and storage. When a customer receives a damaged coil, they will complain. You might have to offer a discount, pay for return shipping, or scrap the product entirely. These losses are 100% preventable. A machine applies wrapping material with perfect, consistent tension and overlap. It covers the vulnerable edges completely, every single time. This ensures the coil arrives at your customer's facility in the same condition it left yours. The reduction in customer complaints and damage claims can be a significant source of savings that many managers overlook.

| Challenge | Manual Process Impact | Automated Solution Benefit |

|---|---|---|

| Efficiency | 15-20 mins per coil, frequent bottlenecks | < 2 mins per coil, continuous flow |

| Safety | High risk of back/strain injuries, high turnover | Eliminates manual handling, drastically lower risk |

| Product Damage | Inconsistent wrapping, high risk of edge damage | Uniform protection, near-zero damage |

| Consistency | Varies by worker, time of day, and fatigue | Every coil wrapped to the exact same standard |

How can automated coil wrapping machines solve these challenges?

You understand the problems with your current process. Now you're thinking about the solution. Maybe you are skeptical. You've heard sales pitches before that promise the world. You worry that a machine might just be a new, expensive problem. An investment in the wrong equipment is a serious mistake. It can disrupt your operations, frustrate your team, and fail to deliver the results you need. But a well-chosen automated coil wrapping machine is different. It is not just another piece of equipment. It is a strategic tool designed specifically to target and eliminate the core problems of manual packaging.

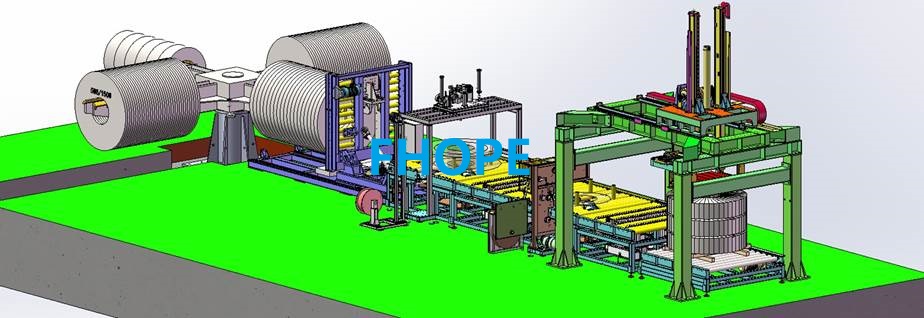

Automated coil wrapping machines directly solve these challenges by replacing slow, dangerous, and inconsistent manual work with a fast, precise, and safe mechanical process. These machines guarantee uniform wrapping, protect the product reliably, and can operate continuously. This leads to a dramatic increase in throughput and a sharp reduction in operational risks and costs.

Dive Deeper: The Transformative Power of Automation

Let's look at exactly how an automated system changes the game. It’s not just about speed; it's about fundamentally changing how your packaging line operates for the better.

A Leap in Speed and Throughput

The most immediate benefit you will see is speed. As I mentioned, a machine can wrap a coil in a fraction of the time it takes a manual team. But it's more than just a faster cycle time. A machine can run 24 hours a day, 7 days a week, with no breaks, no fatigue, and no drop in performance at the end of a long shift. This allows your packaging line to finally keep pace with, or even outpace, your production. Suddenly, the bottleneck is gone. This has a ripple effect throughout your entire plant. You can increase the speed of your slitters and mills, confident that the end of the line can handle the volume. You can schedule shipments more accurately and load trucks faster. I had a client in the steel industry who was struggling to ship 80 coils a day. After installing a simple automatic wrapping line, they were able to consistently ship over 200 coils a day with the same number of production staff. The wrapping machine didn't just make packaging faster; it unlocked the full potential of their entire operation.

Engineering Safety into the Process

A modern packaging line is designed with safety as the top priority. It physically separates your workers from the most dangerous tasks. Instead of people lifting heavy wrapping film or walking on uneven surfaces around a coil, the machine does the work. Heavy coils are moved and positioned by powered conveyors and turnstiles. The wrapping process happens inside a safety cage with interlocked gates. If a gate is opened, the machine stops immediately. Light curtains create an invisible safety barrier; if a person or object crosses it, the system shuts down. Emergency stop buttons are placed at multiple, easily accessible points. This isn't just about meeting regulations. It’s about creating a workplace where your employees feel safe and valued. This leads to better morale, lower turnover, and a culture of safety that benefits everyone.

Perfect Protection, Every Time

Humans are inconsistent. Machines are not. An automated wrapper applies the packaging material with precisely controlled tension and overlap. You can program the machine to apply more layers to the delicate edges and corners of the coil, providing extra protection where it's needed most. It can use a variety of materials, from standard stretch film to VCI paper that prevents rust, or even woven materials for heavy-duty applications. The result is a tight, secure, and weatherproof package that can withstand the rigors of shipping and handling. This consistency means you can be confident that every single coil that leaves your plant is perfectly protected. This builds trust with your customers and strengthens your reputation for quality.

What key features should you look for in a steel coil packaging line?

You are convinced that automation is the right path. But when you start looking at different machines, they can all start to blend together. The specifications seem similar, and every salesperson says their machine is the best. It's a confusing process. If you choose a machine based only on the lowest price or a slick brochure, you could be making a big mistake. You might end up with a machine that is not durable enough for your environment, cannot handle your range of products, or breaks down constantly. To make a smart investment, you need to look past the surface. You must focus on the key features that truly define a high-quality, reliable, and effective packaging line for the steel industry.

When selecting a steel coil packaging line, you must prioritize key features such as heavy-duty, robust construction for durability; operational flexibility to handle various coil sizes and weights; advanced safety mechanisms that exceed basic standards; an intuitive control system for ease of use; and seamless integration capabilities with your existing production flow.

Dive Deeper: A Checklist for a Smart Investment

Choosing the right machine is like hiring a key employee. It needs to be reliable, versatile, and easy to work with. Here are the critical features I always tell my clients to examine closely.

Durability and Construction

A steel plant is a tough environment. There is dust, dirt, and heavy machinery everywhere. A packaging machine built with a flimsy frame or low-quality components will not last. I've seen it many times. A company buys a cheap machine, and within a year, the bearings are shot, the frame is bent, and it's constantly breaking down. Look for a machine with a solid, welded steel frame. Ask about the brand and quality of the key components like motors, gearboxes, and sensors. Are they from reputable, well-known manufacturers? The machine should be designed to withstand the daily abuse of an industrial setting. A heavier, more robustly built machine may cost more upfront, but it will save you a fortune in downtime and repairs over its lifespan.

Flexibility and Adjustability

Your production needs can change. You might run small, narrow coils one day and large, wide coils the next. Your packaging line must be able to adapt easily. Ask the supplier about the machine's range. What are the minimum and maximum coil diameters, widths, and weights it can handle? More importantly, how quick and easy is it to adjust the settings for a different coil size? A modern system should allow your operator to select a pre-programmed recipe from a touch screen, and the machine should adjust its conveyors, rollers, and wrapping parameters automatically. If it requires a mechanic with a wrench and two hours of downtime to change over, it's not a truly flexible solution.

Control Systems and Ease of Use

A powerful machine with a complicated control panel is a recipe for frustration. The system should be easy for your team to learn and operate. Look for a large, clear Human-Machine Interface (HMI) touch screen. The menus should be logical and intuitive, preferably with graphical icons. Can the operator easily adjust parameters like wrapping tension, ring speed, and the number of wrap layers? Does the system provide clear diagnostic information when there is a fault? A good control system empowers your operators to run the machine efficiently and troubleshoot minor issues on their own, without having to call for a senior technician every time. This increases uptime and operator confidence.

| Feature | Why It Matters | What to Look For |

|---|---|---|

| Robust Frame | Long-term reliability in a harsh environment | Heavy-duty, welded steel construction |

| Quality Components | Reduces downtime and maintenance costs | Reputable brands for motors, PLC, sensors (e.g., Siemens, Schneider) |

| Size Flexibility | Handles your full range of products | Wide min/max range for coil OD, ID, width, and weight |

| Easy Changeover | Minimizes downtime between different product runs | Automatic adjustments, programmable recipes on HMI |

| Intuitive HMI | Reduces training time and operator errors | Large, clear touch screen with simple menus and diagnostics |

| Advanced Safety | Protects your people and ensures compliance | Physical guards, light curtains, interlocked gates, E-stops |

| Integration | Creates a smooth, efficient production flow | Compatibility with conveyors, strapping machines, MES systems |

How do you calculate the ROI for a new packaging system?

This all sounds promising, but a new packaging line is a significant capital expense. You can't just walk into your boss's office and say, "I think we should buy this." You need to build a solid business case. You have to prove that this investment will pay for itself and deliver a strong return on investment (ROI). Many managers feel intimidated by this. They worry that if they can't present clear, convincing numbers, the project will be rejected before it even starts. Simply saying "it will be more efficient" is not enough. The good news is that calculating the ROI for this type of equipment is more straightforward than you might think. It's a logical process of adding up your current costs and comparing them to the gains from the new system.

To calculate the ROI for a new packaging system, you must first quantify your annual cost savings. These come from reduced labor expenses, lower material waste, and the elimination of costs from product damage. Then, add the financial value of your increased production throughput. You divide this total annual financial benefit by the initial investment cost to determine the ROI.

Dive Deeper: A Simple Guide to Proving the Value

Let's walk through the steps to build a powerful financial justification for your project. Be conservative with your estimates to make your case even stronger.

Step 1: Calculate Your Current Annual Costs

This is your baseline. You need to be thorough here.

- Labor Costs: How many workers are on your packaging team per shift? How many shifts? Calculate their total annual wages, including overtime, benefits, and payroll taxes. (Example: 4 workers x 2 shifts x €30,000/year = €240,000).

- Product Damage Costs: Look at your records for the last year. How many coils were rejected or discounted due to packaging-related damage? Calculate the total value of this lost revenue. (Example: 2 coils/month x €1,500/coil x 12 months = €36,000).

- Material Waste: Manual wrapping is often wasteful. Estimate how much extra stretch film or paper is used compared to the precise amount a machine would use. This can be 15-20% or more. (Example: 15% waste on €50,000 of material = €7,500).

- Injury & Turnover Costs: This is harder to quantify, but important. Look at your insurance premiums and any direct costs from injuries over the last few years. Estimate the cost of recruiting and training replacements for a high-turnover position. (Example: A conservative estimate might be €5,000 per year).

- Total Current Annual Cost: In this example, €240,000 + €36,000 + €7,500 + €5,000 = €288,500.

Step 2: Estimate New System Costs & Gains

- New Labor Costs: An automated line might only need one supervisor per shift. (Example: 1 worker x 2 shifts x €35,000/year = €70,000).

- Annual Savings: Your savings are the difference between old and new costs. (Example: €288,500 - €70,000 = €218,500 in savings).

- Value of Increased Throughput: This is the most exciting part. If the new line allows you to ship 20 more coils per week, and your profit per coil is €200, what is that worth? (Example: 20 coils/week x 50 weeks x €200/coil = €200,000 in new profit).

- Total Annual Benefit: Savings + New Profit = €218,500 + €200,000 = €418,500.

Step 3: The ROI Formula

Now, you can put it all together. Let's assume the total cost of the new automated line (machine, installation, training) is €350,000.

- ROI Formula: (Total Annual Benefit / Initial Investment Cost) x 100

- Calculation: (€418,500 / €350,000) x 100 = 119% ROI.

- Payback Period Formula: Initial Investment Cost / Total Annual Benefit

- Calculation: €350,000 / €418,500 = 0.84 years, or about 10 months.

A 119% ROI with a payback period of less than a year is a very compelling business case that any manager would be excited to approve.

My Insights: Beyond the Machine - How to Choose the Right Partner?

You have done your homework. You have analyzed the features and calculated the ROI. You are ready to make a decision and purchase a machine. But this is the final, most critical step: who do you buy it from? I have seen many companies make the same mistake. They focus so much on the machine itself that they neglect the importance of the supplier. Choosing the wrong one can be the costliest error of all. A low price tag can be tempting, but if it comes with poor service, no support, and constant problems, that machine will become a permanent headache. Believe me, I built my own factory from the ground up. I know that you are not just buying steel and wires; you are investing in a long-term operational capability.

Choosing the right partner is more important than choosing the specific machine brand. You need a supplier who has deep, proven experience in the steel industry. They must demonstrate a genuine commitment to providing after-sales support, training, and a complete solution that truly solves your problem, rather than just selling you a box.

Dive Deeper: What I've Learned from Building a Factory

This is where I want to share my personal philosophy, which comes from my journey as an engineer, a factory manager, and now a factory owner.

Look for a Teacher, Not a Salesperson

When you talk to a potential supplier, pay attention to the questions they ask. A salesperson will talk about their machine's features. A true partner will ask about your problems. They will want to understand your specific type of steel, your line layout, your production flow, and your biggest headaches. They should be willing to share their knowledge freely, even if it means telling you something you don't want to hear. This is the entire reason I started SHJLPACK. I wanted to create a platform to share the knowledge I gained, to help people like you make informed decisions. A good partner acts like a consultant. Their goal is your success, because your success leads to their success.

Experience You Can Trust

Theory is one thing; real-world experience is another. Has the supplier installed machines in plants like yours? Do they understand the unique challenges of the steel industry in Russia? Ask for case studies. Ask to speak with their other clients. When I work with a new client, I often share stories of how we solved a specific problem for another company. For example, a client had an issue with telescoping coils, and their previous supplier had no solution. We analyzed their line and realized the problem was in the conveyor transition, not the wrapper itself. We designed a simple modification that solved it completely. That is the kind of problem-solving expertise that comes only from years of hands-on experience.

The Critical Importance of After-Sales Support

This is where many suppliers fail. The sale is done, the machine is installed, and then they disappear. What happens when you have a problem a year later? How quickly can you get a qualified technician on-site? How easy is it to get spare parts? A good partner will have a clear and robust plan for after-sales support. They should offer comprehensive training for your operators and maintenance staff. They should have a ready supply of critical spare parts. And they should be able to provide remote diagnostic support to solve many issues over the phone or internet. Before you sign any contract, get a detailed commitment on their service level. This support is your insurance policy for the future.

A Partner in Your Growth

Your business is not static. You will grow and your needs will change. The best partner is one who thinks about your future, not just your present. They should be a resource you can call for advice on optimizing your line, exploring new packaging materials, or planning for future expansion. This is the foundation of a real partnership. It's not a one-time transaction. It's a relationship built on trust and a shared goal of making your operation more successful. This is how I built my business, and it is how I strive to help every single one of my clients grow theirs.

Conclusion

Automating your coil packaging is a powerful strategy for Russian steel plants. Focus on solving your core challenges, choose equipment with robust and flexible features, prove the financial return, and most importantly, select a knowledgeable partner who will support your long-term success.