Your factory floor is a battleground of productivity. In the demanding world of Russian heavy industry, every second counts. But you have a weak link: your coil packing line. It's supposed to be the final step, but instead, it's a constant source of stress. It stutters in the cold, breaks down at the worst possible moments, and requires constant manual intervention that puts your workers at risk. Each time the line stops, you can almost hear the money draining away—in lost output, delayed shipments, and the rising cost of labor to fix the mess. You know there has to be a better way than just hoping the machine makes it through another shift.

To ensure reliable performance of a coil packing line in harsh environments like Russia, you must focus on three core areas. First, select machinery with proven mechanical robustness, including a heavy-duty frame and high-quality components from reputable brands. Second, demand specific modifications for extreme cold, such as low-temperature lubricants, insulated electrical cabinets, and materials that won't become brittle. Finally, you must implement a proactive maintenance schedule with your supplier's support, instead of just reacting to breakdowns.

I understand your frustration because I’ve been there. Before I started SHJLPACK, I was an engineer on the factory floor, and later, I built my own packing machine factory from the ground up. I learned that buying a machine is easy. But buying reliability is different. It’s not about a single feature. It’s about a total solution that considers the machine, the environment, and your entire operational flow. Let's break down how you can secure a packing line that doesn't just work, but works consistently, even under the toughest conditions.

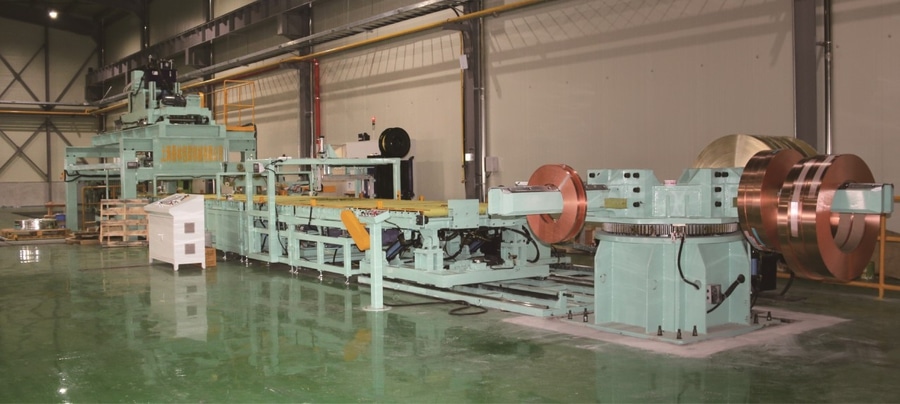

How Can You Judge the Mechanical Robustness of a Coil Packing Line?

You’re looking at a brochure or a technical spec sheet. It's full of numbers and promises of high performance. The salesperson tells you it’s "heavy-duty." But you’ve heard that before. You once invested in a machine that looked strong on paper, only to see its welds crack and its rollers wear out in less than a year. The memory of that expensive mistake makes you cautious. You can't afford to choose wrong again. How do you cut through the marketing and see the machine's true strength?

To accurately judge a coil packing line's mechanical robustness, you must look beyond the spec sheet. Scrutinize the frame construction for thick, continuous welds instead of bolts. Verify the brands of critical components like motors, bearings, and sensors; look for names like Siemens, SEW, or SKF. And finally, evaluate the design of high-wear parts like rollers and grippers to ensure they are made from hardened materials and are easily replaceable.

When I started my own factory, I had a limited budget. I had to make sure every machine I bought would last. I learned to be a detective, looking for clues of quality that aren't always advertised. It’s these small details that separate a machine that lasts for three years from one that runs reliably for over a decade.

Look at the Frame First

The frame is the skeleton of your packing line. If the skeleton is weak, nothing else matters. Many suppliers save costs here, using thinner steel or bolting major sections together. A bolted frame can loosen over time under the constant vibration of heavy coil handling. This leads to misalignment, increased wear on moving parts, and eventual failure.

What you should look for is a frame made from thick structural steel, with clean, continuous welds at all major joints. When I inspect a machine, I run my hand over the welds. Are they smooth and uniform? Or are they spotty and rough? A good weld is a sign of a skilled manufacturing process. I also ask about the steel thickness. For a line handling heavy steel coils, anything less than 8-10mm for the main structural parts is a red flag for me. The machine needs mass to absorb the energy of loading and moving multi-ton coils without flexing. Don't be shy about asking the supplier for pictures or videos of their welding process. A proud manufacturer will be happy to show you.

The Devil is in the Components

A strong frame is just the start. The moving parts are where the daily battle is won or lost. A supplier can build a good frame but then use cheap, no-name components to increase their profit margin. This is a common trap. Your operations team won’t know the difference until the motors start burning out or the sensors start failing.

I insist on knowing the brand of every critical component. It’s not about being a brand snob; it’s about predictable reliability and parts availability.

| Component | Standard (Low-Cost) Option | Heavy-Duty (Reliable) Option | Why It Matters |

|---|---|---|---|

| Main Motor | Generic, unknown brand | Siemens, SEW, ABB | Reliable power, lower energy use, global support. |

| Bearings | Unbranded Chinese bearings | SKF, FAG, NSK | Can handle higher loads and last longer before needing replacement. |

| Sensors | Basic proximity switches | Banner, Omron, SICK | More resistant to dust, oil, and vibration, reducing false readings. |

| Pneumatics | No-name cylinders/valves | Festo, SMC | Less prone to air leaks, ensuring consistent pressure and movement. |

I once visited a client whose new packing line was constantly down. The problem was a small pneumatic valve that kept failing. The supplier had used a cheap, obscure brand. It took two weeks to get a replacement part from overseas. Two weeks of lost production for a $50 part. This is why I always tell my clients: pay a little more for brand-name components. You are not just buying the part; you are buying the global supply chain and the peace of mind that comes with it.

What Special Considerations Are Needed for Operating in Extreme Climates Like Russia's?

Your factory operates in a place where winter is not just a season, but a test of survival. The temperature drops to -30°C or even -40°C. You watch as your equipment, designed for milder climates, starts to fail. Hydraulic oil becomes as thick as honey, making movements slow and jerky. Conveyor belts turn brittle and crack. The grease in bearings solidifies, causing them to seize. Your production schedule doesn't care about the weather, but your machines do. Every cold-related failure is a painful reminder that standard equipment is not good enough.

For extreme climates like Russia's, you need specific modifications. This includes using arctic-grade hydraulic and lubricating oils that maintain viscosity at low temperatures. All electrical cabinets must be insulated and equipped with internal heaters to protect sensitive electronics like PLCs and drives. You must also select materials for belts, hoses, and cables that are certified for low-temperature flexibility to prevent them from cracking.

I remember working on a project for a steel mill in Siberia. They told me stories of workers using blowtorches to heat up gearboxes just to get the line started in the morning. This was not only dangerous but also terrible for the equipment. It became clear to me that a machine for Russia isn't just a standard machine. It has to be engineered for the cold from the very first design drawing.

It Starts with Materials and Lubricants

The wrong materials will fail in extreme cold. It's a simple fact of physics. Standard steel can become brittle. Rubber hoses and seals lose their flexibility and crack, causing hydraulic fluid or air leaks. The plastic insulation on electrical wires can break apart, creating a serious safety hazard.

When discussing a machine for a cold environment, the conversation must include material specifications. Ask the supplier for proof that they are using components rated for your factory's lowest temperatures. For lubricants, it’s not enough to just use any synthetic oil. You need to match the oil's viscosity grade to the operating temperature range.

| Component | Standard Solution | Cold-Weather Solution | Consequence of Failure |

|---|---|---|---|

| Hydraulic Oil | ISO VG 46/68 | Arctic-grade synthetic oil | Slow operation, pump damage. |

| Gearbox Grease | Standard lithium grease | Low-temp synthetic grease | Seized gears, motor burnout. |

| Conveyor Belt | Standard PVC/Rubber | Low-temp rated Nitrile | Cracking, tearing, line stoppage. |

| Electrical Cables | Standard PVC insulation | PUR or TPE insulation | Cracked insulation, short circuits, fire risk. |

Protecting the Brain of the Operation

The most sensitive part of your modern packing line is its electrical control system—the PLC, VFDs, and sensors. These components generate some heat, but in a freezing factory, it's not enough to protect them. Condensation can form inside cabinets as temperatures fluctuate, leading to short circuits. The performance of electronic components can also become unstable at very low temperatures.

The solution is an insulated and heated control cabinet. It's like putting a winter coat on your machine's brain. A simple thermostat-controlled heater inside the cabinet maintains a stable temperature, usually above 5°C, ensuring the electronics work as intended. It's a small extra cost that prevents a massive potential for downtime. When you review a supplier's proposal, look for "cabinet heater" or "climate control" on the parts list. If it's not there, you should ask why.

Why is Proactive Maintenance More Critical Than a Reactive Service Plan?

Your packing line goes down. You make a frustrating call to your supplier's service department. They promise to send a technician, but they are hundreds of kilometers away. It might take them a day, or even two, to arrive. While you wait, your production is at a standstill. Your team is idle, and unshipped products are piling up. You feel completely powerless, dependent on someone else's schedule to fix your problem. This is the very definition of a reactive approach, and it’s a strategy that guarantees lost time and money.

Proactive maintenance is more critical than a reactive service plan because it puts you in control. Instead of waiting for a catastrophic failure, you schedule small, planned maintenance tasks to prevent problems before they start. This approach dramatically increases uptime, extends the lifespan of the equipment, and turns maintenance from an unpredictable cost into a manageable operational expense. A good supplier should not just offer a service hotline; they should provide you with the tools and training to build your own effective maintenance program.

When I ran my factory, I treated my maintenance team as a profit center, not a cost center. Every breakdown they prevented was money earned. This mindset shift is the most important step. Your maintenance crew isn't just there to fix things; their primary job is to stop things from breaking in the first place. This is especially true for equipment in a demanding environment like a Russian steel plant.

The True Cost of "Saving Money" on Maintenance

Some managers try to save money by skipping routine maintenance. This is one of the most expensive mistakes you can make. The cost of a breakdown is never just the price of the replacement part and the technician's time.

Let's do some simple math. Imagine your packing line processes 20 coils per hour, and each coil represents $50 in profit. The line breaks down due to a worn-out chain that would have cost $200 to replace during planned maintenance.

- Downtime: 8 hours (waiting for technician and repair)

- Lost Production: 8 hours * 20 coils/hour = 160 coils

- Lost Profit: 160 coils * $50/coil = $8,000

- Total Cost: $8,000 (lost profit) + technician costs + part cost

You "saved" $200 by skipping maintenance, but it cost you over $8,000. And this doesn't even include the damage to your reputation from delayed deliveries. A proactive approach would have identified the worn chain during a weekly inspection and replaced it during a scheduled 30-minute stop.

What to Demand From Your Supplier

A true partner-supplier wants you to be successful with their machine. They should empower your team, not keep you dependent on their service calls. When you are buying a new packing line, here is what you should demand as part of the package:

- A Detailed Maintenance Manual: Not a generic one, but a manual specific to your machine, with clear instructions and diagrams.

- A Proactive Maintenance Schedule: A checklist of tasks to be performed daily, weekly, monthly, and annually.

- A Recommended Spare Parts List: A list of critical wear parts (like bearings, belts, sensors) that you should keep in your own stock. This list should be divided into "critical" and "recommended" tiers.

- On-Site Training: The supplier's technician should not just install the machine. They should spend at least two days training your operators and your maintenance staff on how to run, troubleshoot, and maintain the line.

Here is a sample of what a simple maintenance schedule might look like:

| Frequency | Task | Checkpoint |

|---|---|---|

| Daily | Visual Inspection | Check for loose bolts, leaks, or unusual noises. |

| Weekly | Lubrication | Lubricate all chains and specified grease points. |

| Weekly | Belt Inspection | Check conveyor and wrapping belts for tension and wear. |

| Monthly | Sensor Cleaning | Clean the lenses of all photoelectric sensors. |

| Annually | Motor Check | Check motor bearings and electrical connections. |

This simple discipline, supported by your supplier, is the key to turning an unpredictable machine into a reliable asset.

What's the One Thing Most Managers Overlook When Buying a Packing Line?

You've done your homework. You have compared technical specifications. You have negotiated the price. You have checked the supplier's references and confirmed they use high-quality components. You've even discussed the need for cold-weather modifications. You feel confident you have covered all the bases to ensure you are buying a reliable, robust machine. The machine arrives, it's installed, and it works perfectly. But then you notice a new problem. A massive queue of coils is waiting to get onto the packing line, while the forklift that takes packed coils away is constantly blocked. You solved one bottleneck, but you just created two new ones.

The single most overlooked factor when buying a packing line is the integration of the machine into your factory's overall material flow. Managers often focus intensely on the machine's specifications (speed, capacity) but fail to analyze how it connects to the processes before and after it. A high-speed packing machine is useless if your cranes can't feed it fast enough or if there's no space to clear the finished products, ultimately failing to improve total throughput.

This is a lesson I learned through painful experience when I was setting up my own factory. I bought a fantastic, high-speed machine, but I placed it in a corner of the workshop that was difficult for our overhead crane to access. The machine was capable of wrapping 30 coils an hour, but we could only ever get 15 coils to it. The machine itself wasn't the problem; my layout was the problem. It was an expensive lesson in the importance of seeing the bigger picture.

Think in "Process," Not Just "Machine"

You are not just buying a machine; you are buying a change to your entire production process. Before you even sign a purchase order, you should map out the entire journey of your product.

Get a drawing of your factory floor and a marker.

- Trace the Upstream Flow: Where does the coil come from? The slitter? The rolling mill? How does it get to the packing area? By crane? By coil car? How much time does that take? Is there a buffer area where coils can wait?

- Analyze the Packing Process: This is where your new machine sits. How does the coil get loaded? How is it positioned? After it's wrapped, where does it go?

- Trace the Downstream Flow: How is the wrapped coil taken away? By forklift? By crane? Where does it go? To a warehouse? Directly onto a truck? Is there enough space for the forklift to maneuver safely and quickly?

This simple exercise will often reveal hidden problems. You might discover that your crane is already at 95% capacity and can't support a faster packing line. Or you might find that the exit path for packed coils conflicts with a major walkway, creating a safety hazard.

The Supplier as a Process Consultant

This is where you can separate a simple "box seller" from a true solutions partner. A good supplier will not just ask you about coil dimensions and desired packing speed. They will ask to see your factory layout. They will ask questions like:

- "What is the cycle time of your slitting line?"

- "What is the lifting capacity and speed of your overhead crane?"

- "Can you show me where the trucks are loaded?"

- "Where will you store the packing materials like stretch film and VCI paper?"

A supplier who asks these questions is thinking about your total success, not just their sale. They understand that if their machine fails to improve your overall efficiency, you will not be a happy customer, even if the machine itself works perfectly. They use their experience from hundreds of other installations to help you avoid common layout and flow mistakes. When you find a supplier who starts the conversation by talking about your process, not just their product, you know you are on the right track. This is the foundation of the "Total Solution" philosophy we built SHJLPACK on.

Conclusion

Ensuring reliability is about more than just the machine. It requires selecting robust hardware, engineering for your climate, and seeing your supplier as a true process partner for the long term.