What Is the One Smart Investment That Russian Factory Owners Are Making in 2025?

Are you a factory manager, constantly feeling the pressure from all sides? You need to increase your output, but your manual packing processes are painfully slow. You are tasked with cutting costs, yet expenses from workplace injuries and product damage are steadily climbing. Every day feels like a battle to keep things running. You've likely dealt with equipment suppliers who promised you the world, only to disappear after the installation, leaving you to handle breakdowns and problems alone. It’s a frustrating position to be in. But what if there was a single, smart investment that could systematically address these core challenges? It’s a strategic shift I’ve seen the most forward-thinking factory owners, especially in demanding industrial markets like Russia, make to secure their future.

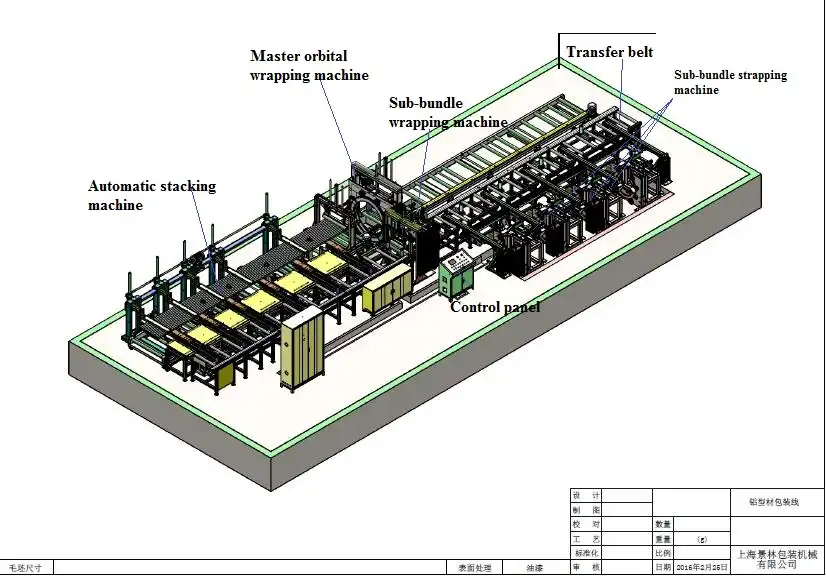

Russian factory owners are making a crucial shift by investing in comprehensive, automated wrapping and packaging lines. They are moving beyond the purchase of a single machine and are now seeking total solutions. These integrated systems combine coil handling, tilting, automatic wrapping, and strapping to eliminate manual bottlenecks, radically improve worker safety, and protect the quality of their final products from factory to customer.

This is more than just an upgrade to new hardware. It is a fundamental change in operational philosophy. It is about building a factory that is more resilient, more profitable, and safer for the people who work there. But how can one strategic decision create such a widespread and positive impact? Let's break it down by looking at the specific problems you likely face on your factory floor every single day.

How Can Automation Solve Your Biggest Production Bottlenecks?

Does the end of your production line look like a constant traffic jam? You have finished steel coils, wire, or pipes piling up, all waiting for a slow, labor-intensive packing process to catch up. This single bottleneck can stall your entire operation, delaying customer shipments and creating chaos on the floor. It is deeply frustrating to have a high-capacity production line running at peak performance, only to see its output choked by the slow pace of manual labor. You know your factory could be producing and shipping more, but you are stuck. This inefficiency costs you money and, over time, damages your reputation for reliable, on-time delivery. The solution is targeted automation. A well-designed packaging line does not just speed things up; it completely redesigns the flow of your products, transforming your biggest bottleneck into your most efficient process.

Automation solves production bottlenecks by creating a continuous, synchronized flow from the end of your production line directly to the shipping bay. An integrated system, which can include coil cars, upenders, and automatic orbital wrappers, handles heavy and awkward products faster and with more consistency than any team of workers ever could. It breaks the logjam that is holding your factory back. This allows your primary production machinery to finally operate at its full, uninhibited potential.

The Anatomy of a Bottleneck

Let's look at what a manual packing station for a product like a steel coil typically involves. First, an overhead crane carefully lowers a heavy coil onto the floor. Then, a team of two or three workers must manually push and position it. They proceed to wrap it by hand with film, a physically demanding and slow task. Next, they have to feed strapping around and under it. Finally, everyone waits for a forklift to become available to move it. Every single one of these steps is a potential delay. If the crane is busy, a forklift is elsewhere, or the team is on a break, the entire production line upstream of them has to stop. I have seen this exact scenario play out in dozens of factories. The bottleneck is not the machine; it is the series of manual handoffs.

The Automated Flow

Now, contrast that with an automated line. The same steel coil comes off the production line and is received by an automated coil car. This car transports it directly to a coil upender, which safely and quickly tilts it from a horizontal to a vertical position. The coil is then fed into an orbital wrapping machine. The machine applies a perfect, consistent layer of protective film in under two minutes. After wrapping, it moves along a conveyor to an automatic strapping station. Once finished, it rests on an accumulation conveyor, ready for dispatch. There is no waiting. There is no manual fumbling or positioning. The process is smooth, continuous, and predictable.

A Real-World Example from My Experience

I remember a client, a factory manager very much like you, who was running a successful metal slitting operation. His slitting line was fast, but his four-man packing team could not keep up. Coils were piling up, and he was considering investing in a second, very expensive slitting machine to meet demand. I went to his factory and spent a day just watching the workflow. I showed him that his problem was not production capacity; it was a packing bottleneck. He was skeptical. We started with a phased plan, first automating the wrapping process. The results were immediate. His packing speed tripled. He was able to reassign three skilled workers to more valuable roles in the factory. The ROI on that single machine was clear in just over a year, and he never had to buy that second slitting line.

| Metric | Manual Packing Process | Automated Packing Line |

|---|---|---|

| Coils Packed/Hour | 5-8, depending on the team | 20-30+ |

| Labor Required | 3-4 workers per shift | 1 supervisor |

| Consistency | Varies by worker and fatigue | 100% consistent wrap |

| Process Time/Coil | 8-12 minutes | 2-3 minutes |

| Production Halts | Frequent due to manual delays | Rare |

Why Is Manual Packing a Bigger Safety Risk Than You Think?

You see your team working hard every day, handling heavy steel coils, bundles of pipe, and other metal products. You have conducted safety briefings, provided steel-toed boots and gloves, and put up warning signs. But you still carry that underlying worry about the risk of a serious accident. You know that one wrong move, one moment of distraction, could lead to a life-changing injury.

The hard truth is that consistent manual handling of heavy, industrial products is an accident waiting to happen. Simple fatigue toward the end of a long shift, a slippery spot on the floor, or a miscommunication between team members can lead to a crushing injury, a severe back strain, or worse. The cost is not just measured in rising insurance premiums or lost workdays. It is the cost to a valued employee's health and the negative impact on the entire team's morale. For any responsible manager, it is a constant, low-level anxiety. By engineering the human element out of the most dangerous tasks—the lifting, turning, and manipulating of heavy loads—you can virtually eliminate these high-risk scenarios. Automation is not just about efficiency; it is the single most effective safety control you can implement.

Manual packing is a significant safety risk because it repeatedly exposes workers to severe ergonomic hazards and the immediate danger of moving heavy loads. Common tasks like manually flipping a coil, bending over to feed strapping, or carrying heavy rolls of packing material are leading causes of chronic back injuries, sprains, and catastrophic crushing accidents. Automation creates a safer work environment by eliminating this direct interaction between people and heavy loads, fundamentally reducing injury-related costs and risks.

The Unseen Costs of a Workplace Injury

When an employee gets hurt, the direct costs are obvious: medical bills and workers' compensation claims. But the indirect, or hidden, costs are often far greater. You lose productivity not just from the injured worker, but also from the team members who stop to help, the supervisors who have to fill out incident reports, and the general disruption to the workflow. You may have to hire and train a temporary replacement. An investigation could shut down the line for hours or days. Over time, a poor safety record makes it harder to hire and retain good employees and can even lead to legal action. These costs add up and directly eat into your factory's profitability.

From Reactive to Proactive Safety

Many factories approach safety reactively. They install a new guardrail after someone nearly falls. They update a procedure after an injury occurs. This is a failing strategy. True safety leadership is proactive. It is about identifying risks and engineering them out of the process before an accident can ever happen. A machine like a coil upender or an orbital wrapper is more than just a piece of equipment; it is a permanent engineering control. It is a solution that prevents an entire category of accidents from being possible. You are not just making the existing process safer; you are replacing a dangerous process with a safe one.

My Personal Commitment to Safety

I will never forget when I was starting my own factory. One of the first people I hired was an experienced operator who walked with a permanent limp. He told me he got it years ago at another company when a steel sheet slipped and crushed his foot. He said something to me that has stuck with me ever since: "Vincent, a machine doesn't get tired. A machine doesn't get distracted." That simple statement shaped my entire philosophy. When I design a packaging line for a client, I do not just see steel coils and conveyors. I see the people who have to work in that environment for eight hours a day, five days a week. Their safety is not a feature; it is the foundation of the entire design.

| Cost Category | Direct Costs | Indirect (Hidden) Costs |

|---|---|---|

| Financial | Worker's compensation, insurance premium hikes. | Lost production time, equipment damage, cost of replacement worker, legal fees. |

| Human | Physical injury, chronic pain, disability. | Lowered morale, increased employee turnover, stress and anxiety across the team. |

| Operational | Line shutdown for investigation and reporting. | Heavy administrative overhead, damage to company reputation, difficulty hiring new talent. |

How Does Proper Packaging Prevent Costly Product Damage and Customer Complaints?

You and your team work incredibly hard to manufacture a perfect product. You adhere to strict quality controls, from raw material intake to the final production step. But then you get that dreaded phone call or email from a customer. The steel coil they received has a dented edge. The beautiful, anodized aluminum profiles are scratched. The product was damaged somewhere between your shipping dock and their facility.

It is one of the most frustrating experiences in manufacturing. All of that precision work and effort, wasted in the final mile. Now you have to deal with processing a return, offering a steep discount, or interrupting your production schedule to remake the order. Your profit on that sale is completely gone. Even worse, your customer's trust in your quality is shaken. A single bad delivery can seriously damage a business relationship that you have spent years building. The solution lies in creating consistent, high-quality, protective packaging. A professional wrapping machine applies protective materials with uniform tension and perfect coverage, creating a tough, resilient shield that manual wrapping can never hope to replicate.

Proper packaging prevents damage by creating a secure, weatherproof, and puncture-resistant barrier around your product. An automatic wrapping machine ensures every part of the product, especially vulnerable edges and surfaces, is covered with consistent tension and overlap. This shield protects against moisture, dust, and impacts during rough handling and transport, drastically reducing customer complaints and the financial losses that come with them.

The Enemies of Your Product in Transit

Once your product leaves your factory, it faces a number of enemies. Moisture in the air and rain can lead to rust and corrosion on steel surfaces. Forklift drivers in a hurry can accidentally dent vulnerable edges. The constant vibration of a truck on the highway can cause products to rub against each other, leading to abrasion and surface scratches. Dust and dirt can work their way into unprotected products, ruining a clean finish. These are the enemies that professional, automated packaging is designed to defeat systematically.

The Science of a Perfect Wrap

A high-quality wrap is about more than just covering the product. There is a science to it that machines execute perfectly every time. For example, an orbital wrapper can be programmed for a specific "overlap" percentage. This ensures that as the film is applied, each layer overlaps the previous one just enough to create a waterproof and airtight seal. Another key factor is "tension control." The system maintains the exact right amount of stretch in the film. This ensures the wrap is tight and secure, but not so tight that it damages the product itself. For products like steel coils, an orbital wrapper is essential because it passes the film through the "eye" of the coil, fully protecting the inner and outer diameters, which are the most easily damaged parts. A manual wrap is always inconsistent; a machine is precise on every single product.

Beyond Protection: The Professional Image

There is another benefit that is often overlooked. A perfectly wrapped pallet or coil looks professional. It arrives at your customer's facility looking clean, secure, and well-cared-for. This sends a powerful, non-verbal message: "We care about our quality at every single step of the process." A messy, loose, hand-wrapped product, even if the product inside is perfect, sends the opposite message. It looks unprofessional and suggests a lack of care. I have had clients tell me that their customers called to compliment them on the new packaging. It builds confidence and strengthens your brand image.

| Problem | Manual Wrapping Weakness | Automated Wrapping Solution |

|---|---|---|

| Edge & Corner Damage | Inconsistent, loose coverage on corners & edges. | A full, tight wrap provides robust cushioning at vulnerable points. |

| Corrosion/Rust | Gaps and holes in the wrap allow moisture in. | Precise overlap creates a waterproof, nearly airtight seal. |

| Surface Scratches | Loose wrap allows products to shift and abrade. | Consistent tension immobilizes the product, preventing friction. |

| Material Waste & Cost | Inconsistent use of film, often too much or too little. | Optimized film stretch and usage reduces material costs by 20-30%. |

What Separates a True Partner from a Simple Machine Seller?

You have likely been in this situation before. A slick salesperson came to your factory and promised that their machine would solve all of your problems. They were very attentive and persuasive during the sales process. But after the machine was installed and the final payment was made, they effectively disappeared. When a technical problem came up, their service department was slow to respond, unhelpful, or nonexistent.

This kind of experience leaves you feeling cynical and rightly cautious. You know you need to invest in new equipment to solve your challenges, but you do not trust the suppliers anymore. You are worried about making another expensive mistake. The reality is, you need much more than just a piece of equipment. You need a reliable expert you can count on for the long term. A true partner invests in your success, not just in making a one-time sale. They begin by seeking to understand your entire operational challenge, offer their expertise long after the installation is complete, and remain committed to helping you grow your business.

A true partner provides a total solution, not just a sellable product. They bring deep industry experience to the table, like that of an engineer or a former factory owner, to help you correctly diagnose your problems, design the right integrated system, and provide meaningful, ongoing support. A machine seller’s job is done after the sale; a partner stays with you to ensure you actually achieve your goals of higher efficiency, improved safety, and greater profitability.

The Transaction vs. The Relationship

A transaction is a simple exchange. It is focused on the features of a machine and its price. The seller's primary goal is to close the deal, and their work is essentially finished once the machine is delivered and paid for. A relationship, on the other hand, is built on delivering value and achieving a successful outcome. As I see it, my job only truly begins after a machine is installed and running in your factory. I am not successful until I see your output numbers go up. I am not successful until your injury rate in the packing area drops to zero. Your return on investment is my final and most important deliverable.

What to Look For in a True Partner

When you are evaluating a potential supplier, you are not just buying a machine; you are choosing a partner. Here are some questions you should ask yourself and them:

- Do they ask questions about your entire process, from production to shipping, or do they only talk about the one machine they want to sell?

- Is their team led by experienced engineers and factory operators, or is it primarily salespeople?

- Do they talk about your ROI, your safety metrics, and your efficiency goals, or just machine specifications?

- Can they show you case studies or connect you with other clients who had problems similar to yours?

- What does their after-sales support structure really look like? Do they offer comprehensive training, keep a stock of critical spare parts, and provide remote diagnostics to get you back up and running quickly?

My Own Journey Is My Proof

My name is Vincent Liu. I did not start my career as a business owner. I started as a packing machine engineer on the factory floor. I have been the one to get the call about a machine breakdown at 3 a.m. I have managed production targets and felt the pressure you feel. Later, I took that experience and built my own successful packing machine factory. I know the challenges of running a manufacturing business because I have lived them myself. I founded SHJLPACK on a simple principle: to be the kind of expert partner that I wished I had when I was running my factory. My mission is not to sell you a machine. My mission is to share what I have learned over decades in this industry to help you solve your problems and succeed. Your growth is the only true measure of my work.

My Final Insight: Why Investing in a Total Solution Is the Key to Long-Term Growth?

You have probably thought about buying a new wrapping machine. Or maybe you have been looking at a new conveyor system. It is natural to look at problems one by one and try to find a single piece of equipment to fix each individual issue. You have a bottleneck, so you buy a faster machine.

But this piecemeal approach often fails to solve the root problem and can even create new ones. The new wrapping machine is now twice as fast as the old conveyor system feeding it, so you have just moved the bottleneck five meters down the line. The new coil upender you bought does not electronically "talk" to the strapping machine, so an operator still has to manually press a button on each machine. You can end up with an expensive collection of individual machines that do not work together as a cohesive system. You have spent a lot of money without truly solving your core operational inefficiency. The most successful and profitable factory owners I work with think differently. They do not buy machines; they invest in fully integrated systems. A total solution is the key to unlocking not just small, incremental improvements, but a fundamental and lasting transformation of your business.

Investing in a total solution is critical because it addresses your entire end-of-line process as one single, synchronized system. Instead of fixing one small bottleneck at a time, an integrated line of material handlers, wrappers, and strappers is designed to eliminate them all. This creates a smooth, efficient, and safe flow from your production line to the shipping truck. This holistic approach delivers a much higher and faster return on investment and builds a strong foundation for future growth.

The Difference Between a 'Machine' and a 'System'

This is a critical distinction. A machine performs a task. A system achieves an outcome. A wrapping machine's task is to wrap. A packaging system's outcome is to get your product out the door faster, safer, and in perfect condition for your customer. The real value is not in any single piece of equipment, but in the intelligent integration of all the components. The system's software ensures the coil car, the tilter, the wrapper, and the conveyor all work in perfect harmony. The value is created in the seamless handoffs between each step.

How a Total Solution Delivers Exponential ROI

The benefits of an integrated system are not just additive; they are multiplicative. Think of it like a formula for success:

(Increased Packing Speed + Reduced Machine Downtime) = Higher Daily Throughput

(Higher Throughput + Zero Product Damage) = Increased Revenue and Higher Profit Margins

(Reduced Manual Labor Costs + Lower Insurance Premiums) = Significant Operational Cost Savings

The ROI does not just come from reassigning one worker. It comes from the combined, compounding impact across your entire operation. You ship more products per day, every product you ship is profitable because it is not damaged, and your operational costs are lower. This is how you gain a serious competitive advantage.

Your Factory in 2025 and Beyond

I want you to imagine your factory floor one year from now. Picture the end of your production line. It is calm, quiet, and organized. A single operator is overseeing a smooth, continuous process. Your factory's total output is up 30%, without adding any new production machinery. You have not had a single safety incident or even a near-miss in the packing area all year. Your biggest customer just called, not with a complaint, but to praise the quality and professionalism of your deliveries. This is not a fantasy. This is the direct result of making one smart, strategic investment in a total solution. It is the outcome I have helped countless factory owners achieve. This is the change that gives you peace of mind as a manager and prepares your business to thrive for the next decade.

Conclusion

Investing in a total automated packaging solution is not an equipment upgrade. It's a strategic move for greater efficiency, uncompromising safety, and sustainable, long-term profitability in your factory.