Is your steel wire rewinding process holding your entire operation hostage? Many factory managers I talk to feel this pressure. They see a slow, labor-intensive packing area that creates a major bottleneck, limiting how much product they can ship out the door. This isn't just an inconvenience; it's a constant drain on your resources. The risk of worker injury from manual handling is high, leading to costly insurance claims and employee turnover. On top of that, inconsistent manual work often leads to damaged products and unhappy customers. But there is a way forward. You can dramatically improve your rewinding efficiency without a massive, budget-breaking investment. It’s about making smart, targeted choices that deliver a real return.

To improve steel wire rewinding efficiency in low-cost operations, you must focus on three key areas: adopting semi-automatic or entry-level automatic machines to reduce manual labor, implementing a strict maintenance schedule to prevent downtime, and providing comprehensive training to operators to maximize machine output and minimize errors. This strategic approach boosts productivity without requiring massive capital investment.

I’ve been in the packing machine industry for a long time, first as an engineer and now as a factory owner myself. I understand the challenges you face because I’ve lived them. The solution isn't always the newest or most expensive technology. The real solution lies in understanding the core of the problem and applying the right tool for the job. In this article, I will walk you through the practical steps you can take. We will look at the real costs of your current process, identify the essential machine features you actually need, and discuss how to build a partnership with a supplier who is invested in your success. Let's begin by uncovering the true cost of staying with your current manual system.

Why is Your Manual Rewinding Process Costing You More Than You Think?

You look at your payroll and see the hourly wages for the workers in your rewinding section. It seems like a clear, manageable expense. You might think that sticking with manual labor is the cheapest way to operate, especially when capital is tight. But the direct labor cost is only the tip of the iceberg. What you don't see on that payroll report are the hidden costs that are quietly eating away at your profits. The constant production delays, the skyrocketing insurance premiums from workplace injuries, and the money lost on scrapped product—these are the real expenses. When you look at the complete picture, you start to see that continuing with a fully manual process is often the most expensive choice you can make.

Your manual rewinding process costs more than just labor because of significant hidden expenses. These include lost production from slow speeds, high worker compensation claims due to safety risks, product damage leading to scrap or rework, and high employee turnover from difficult working conditions. These factors combined create a much higher total cost of operation than the initial labor expenses suggest.

Let's dive deeper and break down these hidden costs. As a factory manager, your goal is to maximize output and control costs. But if you're only looking at wages, you're missing the biggest part of the equation.

The True Cost of Bottlenecks

Think of your production line like a highway. Your manufacturing process might be a three-lane highway, moving at 100 units per hour. But if your manual packing and rewinding section is a single-lane dirt road that can only handle 50 units per hour, your entire factory's speed is limited to 50 units per hour. The efficiency you gained upstream is completely lost at this final stage. This bottleneck means longer lead times, delayed shipments, and potentially lost orders. I once worked with a client whose wire drawing machines were running at only 60% capacity. It wasn't because of a lack of orders; it was because the manual rewinding team couldn't keep up. The cost of that idle capacity was far greater than the cost of a semi-automatic rewinding machine.

The High Price of Poor Safety

This is a point that every responsible manager, like Michael Chen, takes very seriously. Manually handling heavy steel wire coils is physically demanding and dangerous. The most common injuries are back strains and repetitive motion injuries. These aren't just unfortunate accidents; they are a direct cost to your business.

| Cost Factor | Manual Handling | Machine-Assisted |

|---|---|---|

| Worker Injury Risk | High (back strain, repetitive motion) | Very Low |

| Insurance Premiums | Higher due to increased risk rating | Lower |

| Lost Workdays | Frequent | Rare |

| Cost of Replacement Staff | High (training new, temporary staff) | Not applicable |

| Employee Morale | Lower due to physically taxing work | Higher |

Each injury means medical bills, higher insurance costs, and lost productivity. It also hurts morale and leads to higher employee turnover, which means you are constantly spending time and money training new people for a very difficult job. Investing in a machine that does the heavy lifting isn't just about efficiency; it's a fundamental investment in the well-being of your team and the financial health of your company.

Product Damage and Your Reputation

Humans get tired. Consistency is difficult to maintain over an eight-hour shift. In manual rewinding, this can result in loosely or unevenly wound coils. These coils are unstable and prone to damage during transport. The edges of the steel wire can get scratched or dented. When your customer receives a damaged product, it reflects poorly on your company. It leads to complaints, returns, and requests for discounts. In the worst-case scenario, it can cause you to lose a valuable customer. A machine, on the other hand, provides perfect, consistent results every single time. It produces tight, uniform coils that are protected and easy to handle, ensuring the product that leaves your factory arrives at your customer's site in perfect condition.

What Key Features Matter in a Cost-Effective Rewinding Machine?

You've decided to explore new equipment, but the market is flooded with options. Every brochure and every salesperson is promising the most advanced features, the highest speeds, and the best performance, often with a price tag to match. It's easy to feel overwhelmed. You are worried about spending too much on complex features you will never use. Or even worse, you might be tempted by a low price tag only to end up with a machine that is unreliable and breaks down constantly. Making the wrong choice feels like a huge gamble with your limited budget.

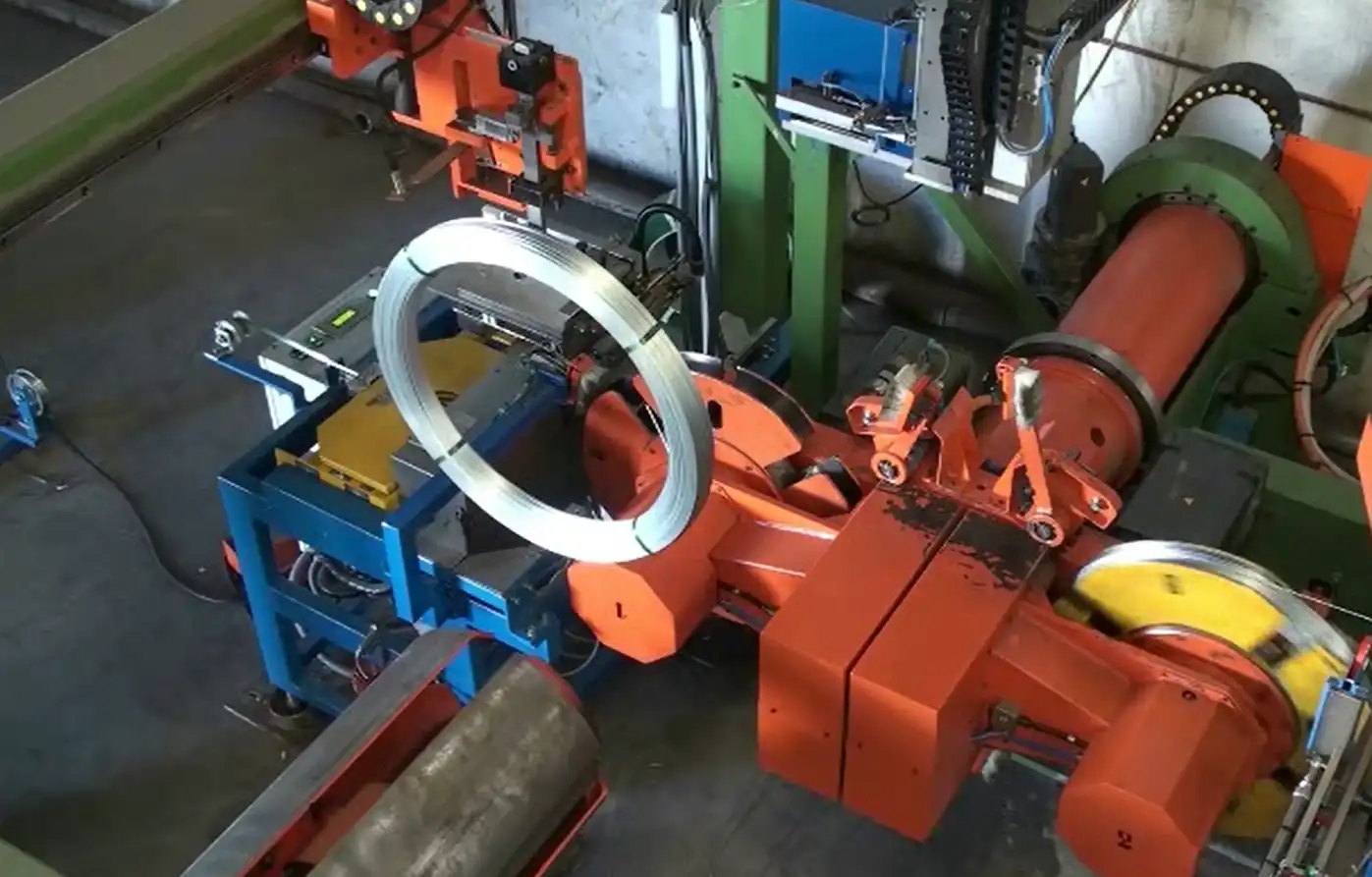

The secret to avoiding this is to ignore the marketing noise and focus on the core features that provide the most value. For a cost-effective and reliable machine, you need to prioritize these key features: a robust and simple mechanical structure for durability, a reliable and user-friendly control system, adjustable speed control to match your production needs, and essential safety features like emergency stops and guarding. Avoid complex, non-essential add-ons to ensure you are paying for reliability and efficiency, not unnecessary complexity.

In my experience building my own packing machine factory, I learned that the most effective machines are not always the most complicated ones. They are the workhorses—the ones that do their job day in and day out without fail. Let's break down exactly what to look for.

Built to Last: The Importance of a Simple, Robust Structure

Your factory is a demanding environment. There's dust, vibration, and constant use. A machine with a flimsy frame or overly complex moving parts is a recipe for disaster. Look for a machine built with a heavy-gauge steel frame. The design should be simple and straightforward. Fewer moving parts mean there are fewer things that can wear out, break, or go out of alignment. When I design a machine for a client, I always prioritize strength and simplicity over flashy, complex designs. A strong foundation ensures the machine can withstand the rigors of a high-production environment for years, providing you with a much better long-term return on your investment.

The Control System: Reliability Over Complexity

The control system is the brain of the machine. Many manufacturers will try to sell you on advanced, proprietary computer systems with touch screens and endless menus. While these can be useful in some very specific applications, they are often overkill for standard rewinding operations. They can also be a major liability. When a proprietary system fails, you are completely dependent on the original manufacturer for service, which can be slow and expensive.

For a cost-effective operation, a standard PLC (Programmable Logic Controller) is the best choice. PLCs are the industry standard for a reason: they are incredibly reliable, durable, and easy to work with. Almost any qualified industrial electrician or technician can troubleshoot and program a PLC, so you are not locked into a single service provider. It gives you control over your own maintenance and repair processes.

Essential Features vs. Costly Add-ons

It is crucial to distinguish between features that add real value and those that just add cost. Here is a simple breakdown to guide your decision:

| Feature | Importance for Low-Cost Ops | Why it Matters |

|---|---|---|

| Variable Speed Control | Essential | Allows you to perfectly match the rewinder speed to your main production line. You can slow it down for delicate materials or speed it up for standard products. |

| Automatic Traversing System | Essential | This system guides the wire back and forth to create a neat, even, and dense coil. This improves product quality and stability for transport. |

| Digital Length Counter | Essential | This ensures every coil has the exact length of wire your customer ordered. It eliminates guesswork, reduces waste, and guarantees order accuracy. |

| Automatic Wire Cutter | Highly Recommended | While you can cut the wire manually, an automatic cutter increases speed and significantly improves safety by keeping the operator's hands away from the process. |

| Fully Automated Loading/Unloading | Nice-to-Have | A fully robotic system is great for very high-volume, 24/7 operations, but it adds significant cost. A semi-automatic system with a simple hoist or tilter often provides the best balance of cost and efficiency. |

By focusing on these essential features, you ensure that your money is spent on what truly matters: reliability, safety, and consistent performance.

How Can Proper Maintenance and Training Turn a Good Machine into a Great Investment?

So, you've chosen and installed your new rewinding machine. The temptation is to consider the job done and move on to the next problem. But purchasing the machine is only the first step. Without a proper plan for its use and care, even the best piece of equipment will fail to deliver its full potential. I've seen it happen many times. Untrained operators run the machine inefficiently, causing frequent small errors that add up. A lack of basic, routine maintenance leads to preventable breakdowns, which can shut down your entire line and result in costly emergency repairs. Your shiny new investment quickly becomes another source of frustration.

The solution is a straightforward, two-part strategy that protects your investment: a proactive maintenance schedule and comprehensive operator training. This simple combination ensures you get the maximum efficiency and lifespan from your machine, turning a good purchase into a truly great long-term investment.

Proper maintenance and training transform a machine into a great investment by maximizing uptime and performance. A routine maintenance schedule prevents unexpected breakdowns and expensive repairs, while comprehensive operator training ensures the machine is run at its optimal speed and capacity, reducing errors, material waste, and the risk of accidents. Together, they guarantee a high return on your investment.

Think of your machine like a car. You wouldn't buy a new car and then never change the oil. The same principle applies here. Let's look at how to implement these two critical components in your factory.

A Proactive Maintenance Plan

Preventative maintenance is always cheaper than reactive repairs. The goal is to catch small issues before they become big, expensive problems. You don't need a complicated system. A simple checklist is often the most effective tool. It should be divided into tasks for operators and more technical checks for your maintenance staff.

Sample Maintenance Checklist

-

Daily Checks (Performed by the Operator at Shift Start):

- Visual Inspection: Walk around the machine. Look for any loose bolts, damaged guards, or visible wire or fluid leaks.

- Cleanliness: Wipe down sensors and remove any dust or debris from the main operating area.

- Listen: When the machine starts, listen for any unusual sounds like grinding, squealing, or knocking.

-

Weekly Checks (Performed by a Maintenance Technician):

- Lubrication: Check and grease all designated points, such as bearings and chains, according to the manufacturer's manual.

- Tension Check: Inspect the tension of all drive belts and chains. Adjust as needed.

- Safety System Test: Physically test all emergency stop buttons and safety interlocks to ensure they are functioning correctly.

This simple routine takes very little time but can save you from days of unplanned downtime.

Training: More Than Just an On/Off Switch

Proper operator training is one of the highest-return investments you can make. An untrained operator might only use the machine at 70% of its capacity because they don't understand how to optimize its settings. A well-trained operator can push that to 95% or more.

I once visited a factory in Mexico that was struggling with output from one of our machines. The manager, a man named Michael, was frustrated. I spent an hour with his main operator. It turned out he was running every wire gauge at the same speed. I showed him how to increase the speed for thicker wires and adjust the traverse to create a denser coil. These small adjustments increased his output by over 20% in one afternoon. It wasn't a problem with the machine; it was a knowledge gap. This is why training must cover more than the basics.

Key Training Modules:

- Safety Procedures: This is always first. Operators must know every safety feature, including emergency stops, guards, and correct procedures for loading and unloading materials.

- Optimizing Machine Settings: Teach them how to adjust speed, tension, and traverse settings for different types of wire. This maximizes both quality and throughput.

- Basic Troubleshooting: Empower your operators to solve simple problems themselves. Show them how to clear a simple wire jam or reset a sensor error. This saves valuable time by not having to wait for the maintenance team for every minor issue.

My Personal Insight: Why Your Supplier is More Important Than the Machine Itself?

You have done your homework. You've analyzed the hidden costs of your manual process. You know the essential features to look for in a machine. You even have a solid plan for maintenance and training. Now, you are ready to contact suppliers and choose the one that offers the best price. This seems like the final, logical step. But this is where many people make their most critical mistake. What happens a year from now when you have a technical question or need a spare part urgently? A supplier who was only focused on making the sale might be slow to respond, or impossible to reach at all. Suddenly, that "low-cost" machine is sitting idle on your factory floor, costing you thousands in lost production every day.

Choosing the right partner is the single most important decision in this process. A vendor just sells you a product. A partner invests in your success. A true partner, especially one who has direct experience running a factory, will provide ongoing support, share valuable knowledge, and work with you to ensure your investment pays off for years to come. This is the difference between buying a tool and gaining an asset.

Your supplier is more important than the machine because a good partner provides crucial long-term value beyond the initial purchase. This includes expert guidance to select the right equipment, reliable after-sales support, quick access to spare parts, and valuable operational advice. A cheap machine from a bad supplier is a liability, while a good machine from a great partner is a genuine asset for growth.

I say this from personal experience. I didn't start my career in an office. I started as an engineer on the factory floor. I know the deep frustration of a critical machine breaking down during a busy shift. I understand the pressure that factory managers like you, Michael, are under to meet deadlines and control costs. When I founded SHJLPACK, I made a promise to myself. I wanted to build the kind of company I wished I could have bought from back then—a company built on expertise and trust, not just sales targets.

The Difference Between a Vendor and a Partner

This distinction is everything. A vendor sees the transaction as the end of the relationship. A partner sees it as the beginning. Here's how to spot the difference:

| Aspect | Vendor (Sales-Focused) | Partner (Solution-Focused) |

|---|---|---|

| Initial Conversation | Asks about your budget first. Pushes a specific model. | Asks about your process, bottlenecks, and goals first. |

| Expertise | Recites specs from a brochure. | Shares insights from real-world factory experience. |

| After-Sales Support | A phone number to a call center. | A direct line to an engineer or technician. |

| Spare Parts | Long lead times, treated as a new sale. | Maintains stock of critical parts for quick shipment. |

| Their Goal | To close the deal. | To solve your problem and help you grow. |

A vendor sells you a machine. A partner provides a total solution.

What You Should Demand From Your Supplier

As the customer, you are in the driver's seat. Don't be afraid to ask tough questions before you sign any purchase order. A good partner will welcome these questions.

- "Can you explain why this specific model is the right choice for my operation?" They should be able to connect the machine's features directly to the problems you described.

- "What does your after-sales support process look like?" Ask for specifics. Who do I call? What is the typical response time?

- "Can I speak with one of your technical experts before I make a decision?" A partner will gladly connect you with an engineer. A vendor will try to keep you with the salesperson.

- "What is your spare parts availability for this model?" They should have a clear answer about what they keep in stock and what the lead time is for other components.

I built my business, SHJLPACK, on the foundation of gratitude for what this industry has given me. It allowed me to achieve my goals and help my clients succeed. Now, my mission is to give back by sharing that knowledge. We don't just sell wrapping machines; we provide the total solution, and that solution starts with a relationship built on trust and a shared goal of making your factory more successful.

Conclusion

Improving rewinding efficiency isn't about new hardware. It's about smart analysis, targeted investment, and choosing a partner who is committed to your factory's long-term success.