Coil Turning Machine Quotation Guide: Cost Factors and Buying Tips

Are you struggling to get accurate pricing for coil turning machines while facing production bottlenecks and safety concerns in your Mexican metal processing plant? As a plant manager, you know that inefficient coil handling can cost your business thousands in lost productivity and potential workplace injuries. The manual flipping of heavy steel coils not only slows down your packaging line but puts your team at risk every single day.

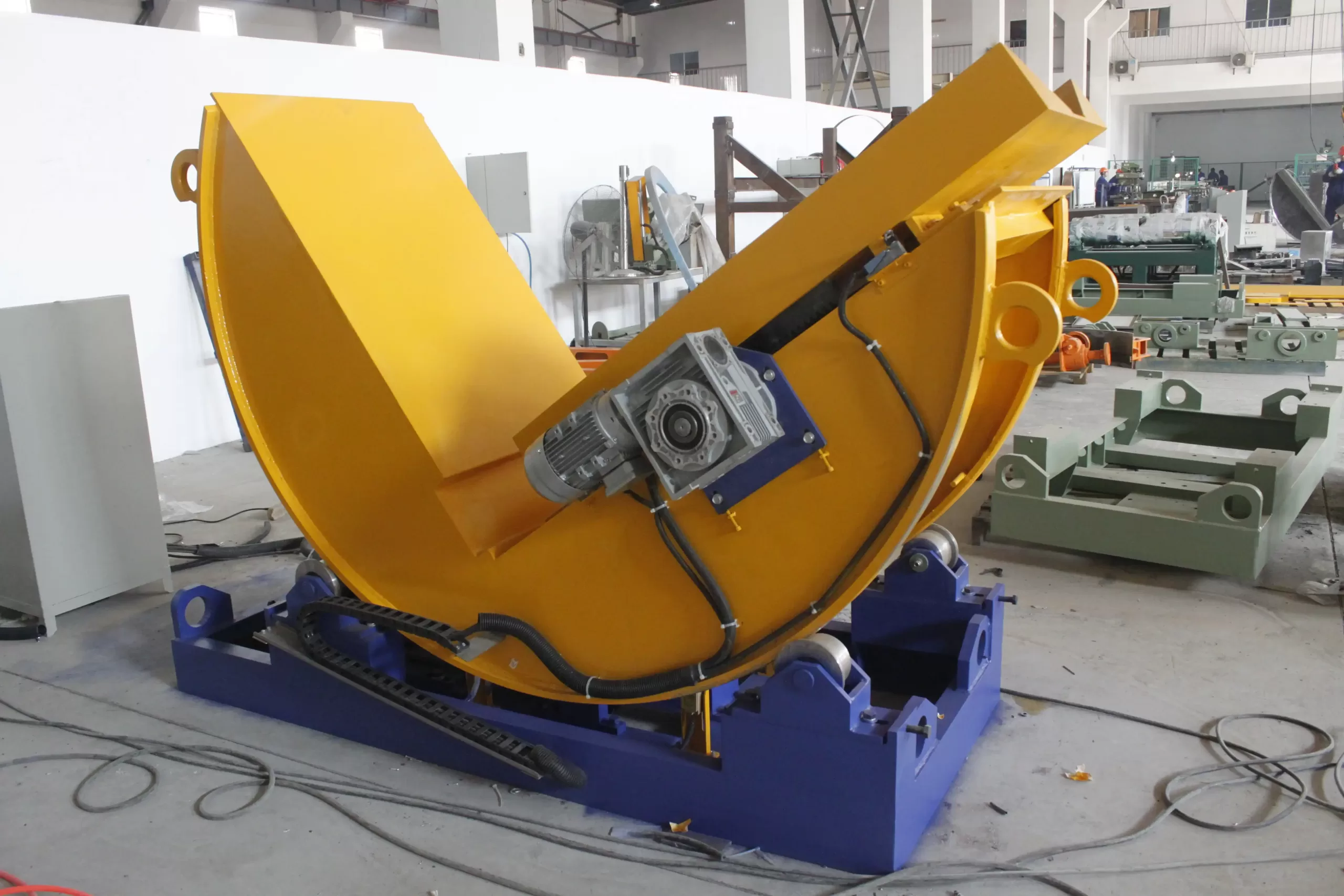

A coil turning machine, also known as a coil upender or tilter, typically costs between $25,000 and $150,000 depending on capacity, automation level, and specific features. The key factors affecting price include: load capacity (2-20+ tons), automation level (manual to fully automatic), safety features, and production speed requirements. For Mexican factories like yours, considering local service support and spare parts availability is crucial for minimizing downtime and ensuring long-term ROI.

Understanding these cost drivers will help you make an informed investment that solves your production challenges while staying within budget. Let's explore what really matters when budgeting for your next coil handling equipment.

Now that you understand the basic pricing range, let's dive deeper into the specific factors that will determine your actual investment and how to choose the right machine for your Mexican operation.

1. What Are the 5 Key Factors That Determine Coil Turning Machine Prices?

When I first started working with Mexican steel plants, I noticed many managers were surprised by the wide price range for what seemed like similar coil turning equipment. The truth is, several critical factors separate basic models from high-performance machines that can transform your production line.

The five primary factors determining coil turning machine costs are: load capacity (2-20+ tons), automation level (manual to smart systems), production speed requirements, safety features, and after-sales service quality. According to Randal Liu, SHJLPACK's founder, "Investing in proper capacity and automation typically delivers 30-50% faster ROI through reduced labor costs and eliminated production bottlenecks." Mexican factories should prioritize machines with robust construction and local technical support to handle intensive operations.

Capacity Requirements: Matching Your Production Needs

The most significant cost driver is your coil weight and size requirements. I've seen factories make the mistake of under-sizing their equipment, leading to premature wear and safety issues:

| Capacity Range | Typical Application | Price Range | Recommended For |

|---|---|---|---|

| 2-5 tons | Small wire coils, light manufacturing | $25,000-45,000 | Small workshops, low-volume production |

| 5-10 tons | Medium steel coils, general metalworking | $45,000-80,000 | Most Mexican metal processing plants |

| 10-20+ tons | Heavy steel coils, automotive industry | $80,000-150,000 | Large steel service centers, automotive suppliers |

⚡ Pro Tip: Always buy 20% more capacity than your current maximum coil weight. This accounts for future business growth and prevents equipment overloading.

Automation Level: Labor Cost vs. Equipment Investment

The automation level directly impacts both upfront cost and long-term operational expenses:

- Manual Systems ($25,000-40,000): Basic hydraulic operation, requires 1-2 operators

- Semi-Automatic ($40,000-70,000): Programmable controls, reduced operator involvement

- Fully Automatic ($70,000-120,000): Integrated with packing lines, minimal staffing

- Smart Systems ($120,000-150,000): AI-powered optimization, predictive maintenance

💰 ROI Calculation Example:

- Manual packing: 3 workers × $1,800/month = $64,800/year

- Automated system: 1 operator × $2,200/month = $26,400/year

- Annual savings: $38,400 | ROI period: ~23 months

Safety Features: Protecting Your Most Valuable Asset

In my two decades in this industry, I've learned that safety features aren't expenses—they're investments in your workforce and business continuity. Essential safety components that affect pricing include:

- Emergency stop systems with redundant backup

- Anti-slip platforms and guarding systems

- Load sensors and imbalance detection

- CE certification and local Mexican NOM compliance

According to industry data, proper safety features can reduce workplace injuries by up to 65% in coil handling operations. For Mexican plants facing high insurance costs, this translates to substantial long-term savings beyond the equipment price.

2. How Much Can You Save with Automated Coil Turning vs Manual Handling?

Many plant managers focus solely on the equipment price tag without calculating the true cost of their current manual processes. When I visit factories across Mexico, I often find hidden expenses that dramatically change the ROI calculation for automation.

Automated coil turning typically saves Mexican factories $40,000-75,000 annually compared to manual handling, with ROI periods of 12-24 months. The savings come from: reduced labor costs (2-3 fewer operators), increased production speed (30-50% faster), eliminated product damage (saves 2-4% of material costs), and lower insurance premiums (15-25% reduction). SHJLPACK's data shows that most clients recover their investment within 18 months through these combined savings.

Labor Cost Breakdown: The Biggest Saving Opportunity

Manual coil handling requires multiple workers for safe operation, while automated systems need minimal supervision. Here's the typical labor comparison:

Manual Process (3-shift operation):

- 3 operators per shift × 3 shifts = 9 operators

- Average Mexican industrial wage: $1,800-2,200/month

- Annual labor cost: $194,400-237,600

- Plus benefits, insurance, training: +25-30%

Automated System:

- 1 supervisor per shift × 3 shifts = 3 operators

- Annual labor cost: $64,800-79,200

- Annual labor savings: $129,600-158,400

Production Efficiency Gains: Doing More with Less

Beyond labor savings, automated coil turning machines dramatically increase your production throughput:

🏭 Case Example: Mexican Steel Service Center

- Challenge: Manual coil turning created bottleneck, limiting packing line to 15 coils/hour

- Solution: SHJLPACK semi-automatic upender with programmable controls

- Results:

- Production speed: Increased from 15 to 22 coils/hour (47% improvement)

- Labor: Reduced from 3 to 1 operator per shift

- Damage reduction: Coil edge damage decreased from 3% to 0.5%

- Annual value created: $85,000 in combined savings and increased output

Hidden Cost Elimination: The Numbers You Might Be Missing

Many factories don't account for these hidden manual handling costs:

- Product Damage: Manual mishandling causes edge damage, leading to customer rejections and material waste (typically 2-4% of product value)

- Workplace Injuries: Back injuries, crushed fingers, and strain account for 25% of metal industry accidents in Mexico

- Insurance Premiums: Factories with automated handling typically see 15-25% lower insurance costs due to improved safety records

- Employee Turnover: Difficult manual jobs have 30-40% higher turnover, requiring constant recruitment and training

When you add these hidden costs, the true expense of manual coil handling often exceeds $300,000 annually for medium-sized Mexican plants.

3. Which Coil Turning Machine Specifications Matter Most for Mexican Factories?

Not all coil turning equipment is suited for the demanding environment of Mexican metal processing plants. Through my work with numerous factories across Mexico, I've identified the specifications that truly impact performance and reliability in local conditions.

The most critical specifications for Mexican factories are: robust construction for heavy-duty cycles, climate-appropriate components (heat and dust resistance), local service support availability, compliance with Mexican NOM standards, and power compatibility with local electrical systems. SHJLPACK machines are specifically engineered for Latin American operating conditions with reinforced frames and locally-sourced critical components to minimize downtime.

Technical Specifications Comparison Table

When evaluating different models, use this comparison framework to identify the best fit for your operation:

| Specification | Basic Model | Recommended Model | Premium Model |

|---|---|---|---|

| Load Capacity | Up to 5 tons | 5-10 tons | 10-20 tons |

| Cycle Time | 2-3 minutes | 60-90 seconds | 30-45 seconds |

| Power Requirements | Standard 220V | Industrial 440V | Heavy-duty 440V |

| Control System | Manual hydraulic | Programmable PLC | Smart IoT-enabled |

| Construction | Standard steel | Reinforced frame | Premium alloys |

| Warranty | 1 year | 2 years | 3+ years |

| Local Support | Limited | Available in major cities | Nationwide coverage |

| Price Range | $25,000-40,000 | $50,000-80,000 | $100,000-150,000 |

Environmental Considerations for Mexican Operations

Mexico's diverse climate conditions require special attention to these components:

- Heat Resistance: Hydraulic systems must withstand ambient temperatures of 35-40°C (95-104°F) without overheating

- Dust Protection: IP54 rating or better for protection against industrial dust in metalworking environments

- Humidity Management: Corrosion-resistant coatings and materials for coastal regions

- Power Stability: Voltage fluctuation protection for areas with inconsistent power supply

According to Randal Liu, "Factories in Monterrey and Mexico City need different specifications than those in coastal areas. Understanding these environmental factors is crucial for equipment longevity."

Maintenance and Service: Planning for the Long Term

The availability of local technical support and spare parts significantly impacts your total cost of ownership:

✅ Must-have service elements for Mexican operations:

- Local Spanish-speaking technicians within 48-hour response time

- On-site training for your maintenance team

- Readily available spare parts inventory in Mexico

- Emergency support hotline with WhatsApp capability

- Regular preventive maintenance programs

I recommend choosing suppliers like SHJLPACK that have established service networks in Mexico rather than importing directly from overseas manufacturers without local presence.

4. How to Evaluate Suppliers and Avoid Costly Mistakes?

Choosing the wrong supplier can turn your equipment investment into a ongoing headache. I've seen too many Mexican factories sacrifice long-term reliability for short-term savings, only to face months of downtime and expensive repairs.

Evaluate coil turning machine suppliers based on: industry experience (minimum 5 years), Mexican market presence, after-sales service capability, client references from similar industries, and financial stability. According to SHJLPACK's customer data, factories that prioritize supplier reliability over lowest price achieve 40% better equipment uptime and 25% lower total cost of ownership over 5 years. Always verify local service capabilities before purchasing.

Supplier Evaluation Scorecard System

Use this quantitative approach to compare potential suppliers objectively:

| Evaluation Criteria | SHJLPACK | Alternative A | Alternative B |

|---|---|---|---|

| Industry Experience | 15+ years | 8 years | 5 years |

| Mexico Presence | Offices in 3 cities | Distributor only | Import only |

| Service Response | 24-48 hours | 3-5 days | 1-2 weeks |

| Warranty Coverage | 2 years comprehensive | 1 year limited | 6 months |

| Spare Parts Availability | Local warehouse | Import required | Import required |

| Client References | 25+ in Mexico | 8 in Mexico | 2 in Mexico |

| Technical Support | Bilingual engineers | Spanish basics | English only |

| Total Score (100) | 92 | 68 | 45 |

Red Flags to Avoid in Supplier Selection

Based on my experience helping Mexican factories, watch for these warning signs:

🚩 Price too good to be true - Significant underbidding often indicates cut corners on components or service

🚩 Vague warranty terms - Look for specific coverage details and exclusion clarity

🚩 No local references - Always speak with existing Mexican clients about their experience

🚩 Poor communication - If they're unresponsive during sales, service will be worse

🚩 Limited technical documentation - Professional suppliers provide detailed manuals and drawings

The Smart Procurement Process: Step by Step

Follow this proven process to minimize risks in your coil turning machine purchase:

- Needs Assessment (1-2 weeks): Document your specific requirements, production volumes, and space constraints

- Supplier Shortlisting (1 week): Identify 3-5 qualified suppliers with Mexican experience

- Technical Proposal Review (2 weeks): Evaluate detailed proposals with your engineering team

- Reference Checks (1 week): Contact existing clients, especially those in similar industries

- Factory Visit (optional but recommended): See their manufacturing capability firsthand

- Final Negotiation (1-2 weeks): Discuss pricing, payment terms, delivery, and service agreements

- Contract Finalization (1 week): Ensure all terms, warranties, and service levels are documented

💰 Negotiation Tip: Focus on total cost of ownership rather than just purchase price. Sometimes paying 10-15% more for better service support saves you 30-40% in long-term maintenance and downtime costs.

Conclusion

Choosing the right coil turning machine requires balancing initial investment with long-term operational benefits. By focusing on capacity, automation, and supplier reliability, Mexican factories can achieve significant efficiency gains and cost savings. For complete packaging solutions, consider integrating with a full steel coil packing line to maximize your automation investment.

Frequently Asked Questions

Q: What is the typical delivery and installation time for coil turning machines in Mexico?

A: Standard delivery takes 4-8 weeks after order confirmation, with installation and commissioning requiring 3-5 days. SHJLPACK maintains partial inventory in Mexico for faster delivery of popular models, potentially reducing wait times to 2-3 weeks for urgent requirements.

Q: How often do coil turning machines require maintenance in industrial environments?

A: Basic maintenance should be performed weekly (visual inspections) with comprehensive service every 500 operating hours or quarterly. Hydraulic systems need fluid changes annually, while mechanical components typically require lubrication every 200 hours in demanding Mexican industrial conditions.

Q: Can existing manual coil handling be partially automated instead of full replacement?

A: Yes, retrofitting solutions are available that can automate specific aspects like positioning or control systems. SHJLPACK offers upgrade packages starting at $15,000-25,000 that can improve safety and efficiency while preserving some existing equipment, though complete replacement often delivers better long-term value.

Q: What training is typically provided for operators and maintenance staff?

A: Reputable suppliers provide 2-3 days of on-site operator training and 1-2 days of maintenance technician training. SHJLPACK includes bilingual training materials and ongoing support, with advanced maintenance courses available for complex troubleshooting and repair procedures.

Q: How does power consumption compare between manual and automated coil turning systems?

A: Automated systems typically consume 15-25 kW during operation compared to 5-8 kW for basic hydraulic manual systems. However, the higher energy cost is significantly offset by labor savings, with most Mexican factories achieving net operational savings of $3,000-6,000 monthly despite increased electricity usage.