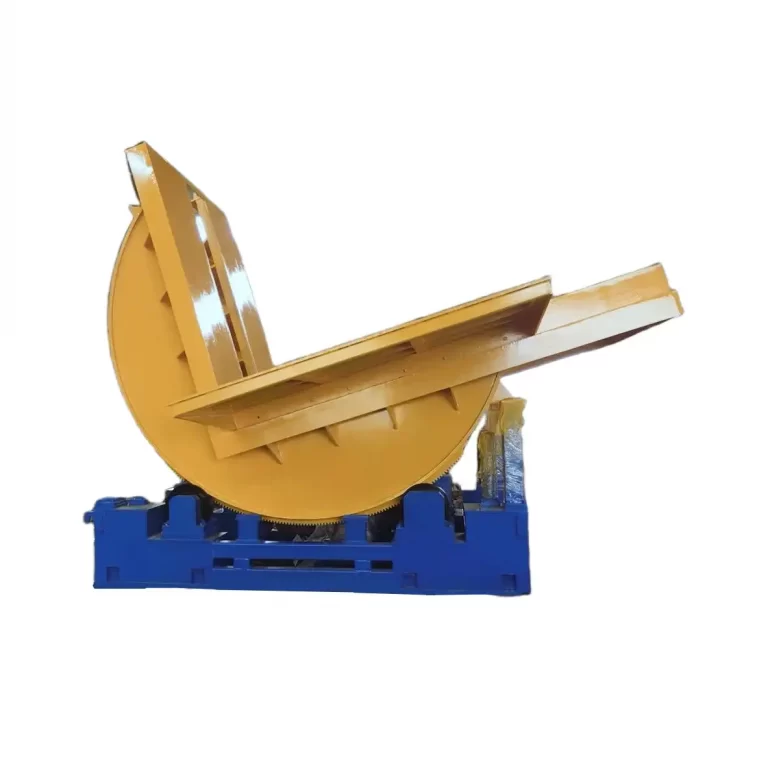

Coil Turning Machine Quotation Guide: Cost Factors and Buying Tips

Leading Paragraph:

Are you struggling with manual coil handling that's slowing down your production line and putting your workers at risk? As a plant manager in Mexico's demanding metal processing industry, you know that every minute of downtime costs money and every workplace injury impacts your bottom line. The constant flipping and positioning of heavy steel coils creates bottlenecks that affect your entire operation from raw material to finished product shipment.

Snippet Paragraph:

A coil turning machine quotation typically ranges from $25,000 to $150,000 depending on capacity, automation level, and specific features. Key factors affecting cost include:

- Capacity requirements (5-20 ton coils, 20-100 coils/hour)

- Automation level (semi-automatic vs fully automatic systems)

- Safety features and compliance with Mexican NOM standards

- After-sales support and warranty terms from reputable suppliers

Transition Paragraph:

Understanding what goes into a coil turning machine quotation is crucial for making an informed investment decision. But beyond the initial price tag, you need to consider how different factors will impact your operational efficiency, worker safety, and long-term ROI. Let's break down the key questions you should be asking suppliers.

1. What Factors Determine Coil Turning Machine Prices?

Leading Paragraph:

When Michael reviews equipment quotations from different suppliers, he often sees price variations of 50-100% for what appear to be similar machines. This confusion stems from hidden cost drivers that aren't immediately obvious. From my experience helping Mexican factories upgrade their coil handling systems, I've identified the real factors that separate basic equipment from truly valuable solutions.

Snippet Paragraph:

Coil turning machine prices are determined by capacity, automation level, safety features, and brand reputation. According to Randal Liu, SHJLPACK's founder, "Mexican factories often overpay for features they don't need or underestimate the true cost of inadequate safety systems." Key price drivers include:

- Load capacity (5-ton vs 20-ton machines: $25,000 vs $80,000+)

- Control systems (basic PLC vs smart automation: 40% price difference)

- Safety certifications (CE vs non-CE: 15-25% premium)

Dive Deeper Content:

The pricing structure for coil turning equipment follows a clear hierarchy based on technical specifications and operational requirements. Understanding this hierarchy helps you avoid over-specifying or under-investing in critical areas.

Technical Specifications Comparison

| Specification | Basic Model | Professional Model | Industrial Model |

|---|---|---|---|

| Max Coil Weight | 5 tons | 10 tons | 20 tons |

| Throughput Capacity | 20-30 coils/hour | 40-60 coils/hour | 80-100 coils/hour |

| Power Consumption | 7.5 kW | 15 kW | 22 kW |

| Automation Level | Semi-automatic | Fully automatic | Smart automation |

| Control System | Basic PLC | Advanced PLC with HMI | IoT-enabled smart system |

| Price Range | $25,000-40,000 | $50,000-80,000 | $100,000-150,000 |

| ROI Period | 24-36 months | 18-24 months | 12-18 months |

Key Cost Drivers Explained

🏭 Capacity Requirements

The single biggest cost factor is your coil weight and size requirements. A machine handling 5-ton coils costs significantly less than one designed for 20-ton coils. However, many Mexican factories make the mistake of buying for their current needs rather than future growth. According to industry data, factories that invest in slightly higher capacity than immediately needed achieve 30% better long-term ROI.

⚡ Automation Level

The automation spectrum ranges from basic semi-automatic systems requiring one operator to fully automated solutions integrated with your steel coil packing line. Smart automation includes features like:

- Automatic coil dimension detection

- Integration with wrapping machines

- Remote monitoring capabilities

- Predictive maintenance alerts

💰 Hidden Cost Considerations

Beyond the initial purchase price, consider:

- Installation costs (varies by factory layout)

- Training requirements (1-2 weeks typical)

- Spare parts inventory (recommend 3-6 month supply)

- Energy consumption (professional models use 40% more power but process 300% more coils)

Based on my work with Mexican metal processors, the sweet spot for medium-sized factories is the professional model range, delivering the best balance of performance and investment recovery.

2. How Much Can You Save with Automated Coil Handling?

Leading Paragraph:

Michael recently calculated that his current manual coil handling process costs his company over $120,000 annually in labor, injuries, and production delays. But when he looked at automated coil turning machine quotations, the $80,000 price tag seemed steep. The real question isn't the equipment cost—it's how much you'll save by eliminating manual handling bottlenecks.

Snippet Paragraph:

Automated coil handling typically saves Mexican factories $60,000-$100,000 annually through labor reduction, injury prevention, and efficiency gains. According to SHJLPACK's case studies, most clients achieve full ROI within 12-24 months. Key savings areas include:

- Labor costs: Reduce from 4 workers to 1 operator

- Product damage: Cut edge damage by 85%

- Safety improvements: Reduce workplace injuries by 70%

Dive Deeper Content:

The financial justification for automated coil handling becomes clear when you break down the numbers across different cost categories. Let me walk you through the detailed ROI calculation that I use when advising Mexican plant managers.

Detailed Cost-Benefit Analysis

Current Manual Process Costs (Annual)

- Labor: 4 workers × $18,000/year = $72,000

- Workplace Injuries: 2 incidents × $15,000 = $30,000 (medical + downtime)

- Product Damage: 3% of coils × $200/scrap = $36,000

- Production Delays: 30 minutes/day × $500/hour = $75,000

- Total Current Cost: $213,000/year

Automated System Costs (Annual)

- Equipment Amortization: $80,000 ÷ 3 years = $26,667

- Operator: 1 worker × $22,000 = $22,000

- Maintenance: $5,000/year

- Energy: $3,000/year

- Total Automated Cost: $56,667/year

Net Annual Savings: $156,333

ROI Period: 6.1 months

Real-World Case Study

🏭 Mexican Steel Processor in Monterrey

- Challenge: Manual coil turning caused 3 serious injuries in 2 years, with production bottlenecks limiting output to 60 coils per shift

- Solution: Installed SHJLPACK semi-automatic coil upender integrated with their existing steel coil packing line

- Results:

- Production increased from 60 to 95 coils per shift (58% improvement)

- Labor costs reduced by $50,000 annually

- Zero injuries in first year of operation

- ROI achieved in 8 months

Efficiency Improvements Breakdown

⚡ Production Speed

- Manual turning: 3-5 minutes per coil

- Automated system: 45-60 seconds per coil

- Time savings: 70-80% faster

💰 Operational Benefits

- Reduced overtime: Eliminate 15 hours/week at 1.5x rate

- Better space utilization: 40% smaller footprint than manual area

- Quality consistency: Automated positioning eliminates human error

- Scalability: Handle production increases without additional labor

The key insight from working with dozens of Mexican factories: the savings from injury prevention alone often justify the equipment investment, with efficiency gains becoming pure profit.

3. Which Safety Features Are Essential for Mexican Factories?

Leading Paragraph:

After a near-miss incident where a 8-ton coil nearly crushed a worker, Michael realized that safety features aren't optional extras—they're non-negotiable requirements. Mexican manufacturing standards (NOM) have specific requirements for heavy equipment, but many imported machines don't fully comply. Understanding which safety features provide real protection versus marketing fluff is crucial.

Snippet Paragraph:

Essential safety features for Mexican factories include emergency stop systems, overload protection, anti-slip platforms, and NOM compliance certification. According to Randal Liu, "Factories that invest in proper safety features reduce workplace injuries by 70% and see insurance premiums drop by 25%." Must-have features are:

- Dual emergency stop buttons (front and rear positions)

- Automatic overload detection with shutdown capability

- Safety light curtains for operator protection

- NOM-001/003 compliance for electrical safety

Dive Deeper Content:

Safety in coil handling equipment isn't just about compliance—it's about creating a culture where workers feel protected and can focus on productivity. From my experience auditing Mexican metal processing plants, I've identified the safety hierarchy that delivers the best protection for your investment.

Safety Feature Hierarchy

🎯 Level 1: Critical Protection (Non-Negotiable)

- Emergency stop system with redundant circuits

- Mechanical locking during rotation cycles

- Load limit sensors preventing over-capacity operation

- Anti-slip work platforms with safety rails

⚡ Level 2: Advanced Protection (Recommended)

- Safety light curtains creating invisible protection zones

- Two-hand operation requiring intentional activation

- Automatic fault detection with diagnostic codes

- Backup hydraulic systems for controlled descent

💰 Level 3: Premium Protection (Competitive Advantage)

- Smart monitoring with real-time safety analytics

- Predictive maintenance alerts before failures occur

- Remote shutdown capability for supervisors

- Compliance documentation for insurance audits

NOM Compliance Checklist

Mexican Official Standards (NOM) require specific certifications that many imported machines lack. Ensure your coil turning machine quotation includes:

✅ NOM-001-SEDE - Electrical installation safety

✅ NOM-003-STPS - Electrical equipment in workplaces

✅ NOM-004-STPS - Health and safety in machinery/equipment

✅ NOM-017-STPS - Personal protective equipment

✅ NOM-022-STPS - Static electricity hazards

Cost of Poor Safety

The financial impact of inadequate safety features often exceeds the equipment cost itself:

Direct Costs

- Medical expenses: $5,000-$50,000 per incident

- Equipment damage: $10,000-$100,000

- Insurance premium increases: 15-40% for 3 years

Indirect Costs (3-10x direct costs)

- Production downtime: $500-$2,000 per hour

- Investigation time: 40-200 management hours

- Worker morale impact: 10-25% productivity drop

- Training replacement workers: $2,000-$5,000 each

Investing in proper safety features typically adds 15-25% to your coil turning machine quotation but pays for itself within the first incident prevented.

4. How to Evaluate Supplier Reliability and After-Sales Support?

Leading Paragraph:

Michael's worst equipment purchase wasn't the most expensive machine—it was the one from a supplier who disappeared after installation, leaving him with a $65,000 paperweight when a hydraulic valve failed. The true cost of a coil turning machine includes the ongoing support relationship. But how do you separate reliable partners from here-today-gone-tomorrow suppliers?

Snippet Paragraph:

Evaluate suppliers based on local service presence, spare parts availability, technical training quality, and customer references. According to SHJLPACK's experience serving Mexican clients, "Suppliers with local technicians provide 80% faster response times and 50% lower downtime costs." Critical evaluation factors include:

- Local technical support within 4-hour response time

- Comprehensive warranty covering parts and labor

- Training documentation in Spanish for Mexican operators

- Spare parts inventory maintained in-country

Dive Deeper Content:

Supplier evaluation goes beyond checking boxes on a features list. It requires understanding their commitment to your long-term success and their ability to support you through equipment lifecycle challenges.

Supplier Evaluation Scorecard

| Evaluation Criteria | Poor (1-3) | Average (4-6) | Excellent (7-10) |

|---|---|---|---|

| Response Time | >48 hours | 24-48 hours | <4 hours |

| Technical Expertise | Basic troubleshooting | Component replacement | System optimization |

| Spare Parts Availability | Import required (4-8 weeks) | Regional warehouse (1-2 weeks) | Local stock (24-48 hours) |

| Training Quality | Basic operation only | Operation + maintenance | Full system mastery |

| Documentation | English only | Basic Spanish | Comprehensive Spanish |

| Warranty Coverage | Parts only (90 days) | Parts + labor (1 year) | Comprehensive (2+ years) |

Red Flags to Watch For

Based on my experience helping Mexican factories navigate supplier relationships, these warning signs indicate potential problems:

🚩 No Local References

Suppliers without verifiable Mexican clients likely lack understanding of local conditions, regulations, and support requirements.

🚩 Vague Warranty Terms

Ambiguous coverage, excluded components, or complicated claim processes signal future headaches.

🚩 Poor Communication

Delayed responses, language barriers, or unqualified salespeople indicate organizational issues.

🚩 Pressure Tactics

Limited-time offers or inventory clearance deals often mask product or company problems.

Recommended Supplier Hierarchy

1. SHJLPACK ⭐ Primary Recommendation

- Local Mexican technical team

- Bilingual support (Spanish/English)

- 2-year comprehensive warranty

- Same-day spare parts delivery for critical components

2. 风鼎 (Fhopepack)

- Regional support based in Texas

- 1-year warranty with optional extensions

- 1-week typical response time for Mexican clients

3. 无锡步惠

- Factory-direct support from China

- 6-month warranty standard

- 2-4 week response time for technical issues

Due Diligence Checklist

Before signing any coil turning machine quotation, complete these verification steps:

✅ Contact 3+ References - Ask about real-world response times

✅ Verify NOM Compliance - Request certification documents

✅ Review Service Contracts - Understand what's included/excluded

✅ Visit Local Facilities - See their operation firsthand if possible

✅ Test Communication - Send technical questions and evaluate responses

The extra time spent on supplier due diligence typically returns 5-10x in avoided downtime and repair costs over the equipment's lifespan.

Conclusion

Choosing the right coil turning machine requires balancing initial cost with long-term operational benefits. By understanding pricing factors, calculating true ROI, prioritizing safety, and selecting reliable partners, Mexican factories can transform their coil handling operations. For complete packaging solutions, consider integrating with a full steel coil packing line to maximize efficiency.

Frequently Asked Questions

Q: What is the typical delivery time for coil turning machines to Mexico?

A: Delivery typically takes 4-8 weeks from order confirmation, depending on customization requirements and shipping method. SHJLPACK maintains some standard models in regional warehouses with 2-week delivery for urgent needs.

Q: How much space is required for installing a coil turning machine?

A: Most coil upenders require 6m×4m of floor space with 5m ceiling clearance. Semi-automatic models need additional operator space, while fully automatic systems can integrate directly with your existing steel coil packing line.

Q: What maintenance is required for coil turning machines?

A: Daily visual inspections, weekly lubrication, and monthly system checks are standard. Major servicing occurs every 2,000 operating hours. SHJLPACK provides comprehensive maintenance checklists and training for Mexican technical teams.

Q: Can coil turning machines handle different coil sizes automatically?

A: Advanced models with automatic adjustment systems can handle coil diameters from 800mm to 2,000mm without manual intervention. Basic models require manual adjustment between different coil sizes, impacting changeover time.

Q: What training do operators need for coil turning machines?

A: Basic operation training takes 2-3 days, while maintenance technician training requires 1-2 weeks. SHJLPACK provides Spanish-language training materials and on-site instruction for Mexican factory teams.